The origin of 5 axis CNC machining can be traced back to the first CNC machine tool developed by John Parsons in the 1950s. Since then, the technology has been developed to manage the motion axes in five directions at a time. Engineers simply need to input the computer with the three-dimensional design sketches, and the tool can function like a skilled engraver, gradually carving the metal block into complex components.

Although it is often said that such a machine is hard to operate and expensive, its practical application is far more extensive than imagined. Its real advantage lies in the fact that by completing multi-angle machining in a single clamping, it eliminates the errors and labor hours spent on repeated clamping.

What in the world makes both aerospace parts and daily necessities possible to produce? Is its working challenge and cost overhyped? Let us start from scratch and lead you to relearn this technology that reshapes the manufacturing sector rules.

What is 5 axis CNC machining?

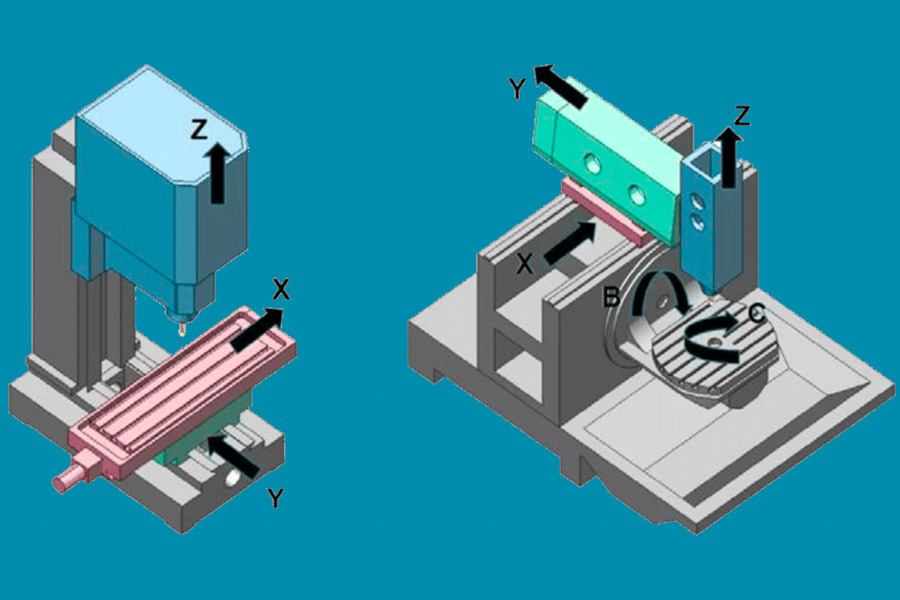

The idea behind 5 axis machining is that the tool can move in five directions, two of which also rotate. This type of processing belongs to the process of multi-axis cutting and forming, which resembles the use of the machine tool as a carving knife to cut the metal raw material into a smooth surface or complex structure step by step.

The most comfortable part is that during processing, there is no need to repeatedly disassemble and readjust the parts like in the traditional approach. The machine can itself regulate the cutting angle, and what is even more astonishing is that it is capable of continuous cutting in a single pass.

For example, the machining of high-precision parts such as turbine blades, which in the past required seven or eight operations, can now be cut in circular slices on a five-axis machine tool, doubling productivity.

The core principle can be divided into three key points:

(1)Five-way coordinated motion

The machine tool uses a combination of three linear axes (X/Y/Z axes responsible for forward and backward, left and right, and up and down movement) and two rotation axes (usually marked as A/C axes) to enable the tool to approach the workpiece at any angle in space. For example, when making turbine blades, the tool can cut vertically and tilt 45 degrees to cut sideways.

(2)Advantages of non-flipping processing

Traditional 3 axis machine tools need to disassemble and adjust the direction of the workpiece many times when processing complex parts, while the 5 axis system automatically switches the processing surface through the rotation axis. Just like shooting an object with a panoramic camera, there is no need to manually rotate the subject, and the lens can capture all angles around it.

(3)Dynamic synchronization accuracy

The tool cutting and workpiece rotation can be coordinated in real time. When processing special structures such as spiral grooves, the spindle moves forward while the workpiece rotates at a constant speed. The two are synchronized at the millimeter level through the CNC system, and the final molding accuracy can reach 0.005mm.

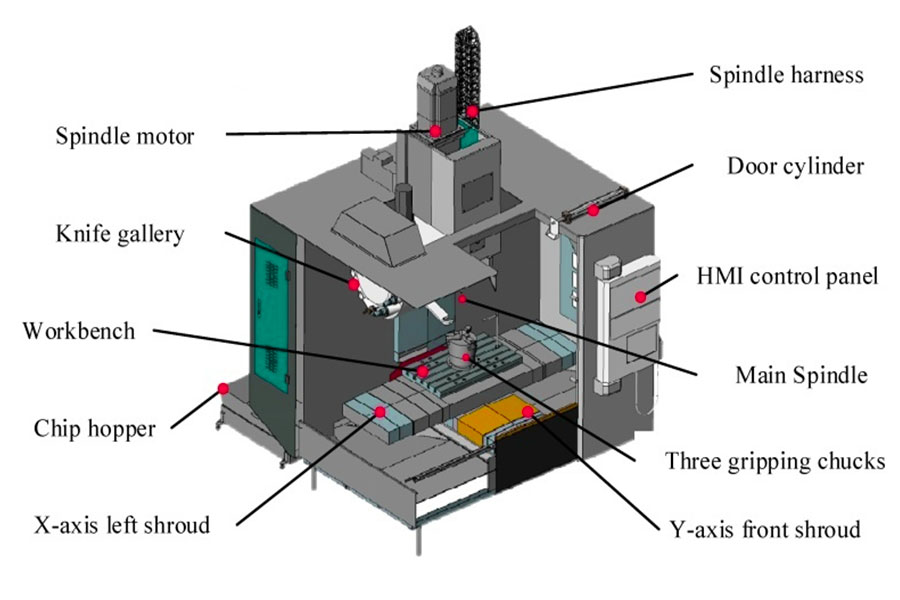

What are the key components of a 5 axis CNC machining center?

1.The main structure of the machine tool

It can be understood as the "skeleton" of the equipment, which is generally made of cast iron or steel structure to support all parts. If the basic frame is not strong enough, it is easy to vibrate during high-speed cutting, which may eventually cause dimensional deviations in the parts.

When selecting equipment, 5 axis CNC machining service provider will focus on the rigidity of the frame, especially when processing hard materials such as aviation titanium alloy, a heavy frame must be used.

2.The structure of the five motion axes

This is the core of the five-axis! The following is a structural description of the five-axis machine tool motion system:

| Movement axis | Direction of movement | Function description |

| X-axis | The workbench moves vertically and horizontally. | Forming the basic machining path, the essential core motion axis for all CNC equipment. |

| Y-axis | Horizontal movement perpendicular to the X-axis. | Cooperate with the X-axis to expand the plane processing range and form two-dimensional processing capability. |

| Z-axis | The tool moves vertically up and down. | Controlling the precision of machining depth directly affects the depth dimension of the mold cavity. |

| A-axis | Rotating motion around the X-axis. | Realize workpiece angle adjustment to meet the requirements of inclined surface machining. |

| B axis | Rotating motion around the Y-axis. | Collaborate with the A-axis to enhance spatial processing capabilities and expand the working angle range of the machine tool. |

To process a twisted turbine blade, the worktable rotates while the tool tilts, and all the arcs can be processed at once without repeatedly disassembling and assembling parts.

3.Spindle system

The spindle system is the core unit of the machine tool to achieve cutting processing, and the speed can range from several thousand to tens of thousands of revolutions per minute.

- High speed is suitable for fine processing (such as polishing the metal shell of a mobile phone).

- High torque is suitable for rough processing (such as digging deep grooves in steel parts).

The selection of this system is directly related to the business capabilities of 5 axis cnc machining center manufacturers, the 12,000rpm spindle of ordinary 3 axis equipment can only handle conventional metal cutting, while the 40,000rpm high-speed spindle configured in the 5 axis linkage machining center can undertake micro-processing orders for precision instruments such as medical bone drills.

4.CNC system and software

The CNC system is responsible for converting design drawings into machine tool action instructions, including hardware such as operation panels and processors, as well as special software from brands such as Siemens.

The software can automatically plan the 5 axis linkage path. For example, when machining an impeller, the system will automatically avoid the collision position between the tool and the workpiece, reducing the difficulty of manual adjustment. This intelligent control allows novices to complete complex parts machining while ensuring machining accuracy.

5.Tool magazine and tool changer

To store tools and complete automatic switching during machining. Mini 5 axis CNC machining center is usually equipped with 12-24 tools, while large equipment can be expanded to more than 200 tools to meet the needs of multi-process machining of complex parts. When the 5 axis CNC machining service accepts small batch orders, it can save time by changing tools quickly. For example, aluminum alloy is made in the morning, and stainless steel is cut directly in the afternoon.

6.Auxiliary accessories

- Coolant nozzle: Spray water or oil while cutting to prevent the material from overheating and deformation.

- Chip conveyor: Clean metal debris like a vacuum cleaner to avoid scratching the workpiece.

- Real case: A medical device factory found a five-axis service provider to process joint prostheses, but the other party did not adjust the coolant properly, and the stainless steel surface was full of burn marks, and the entire batch of parts was scrapped.

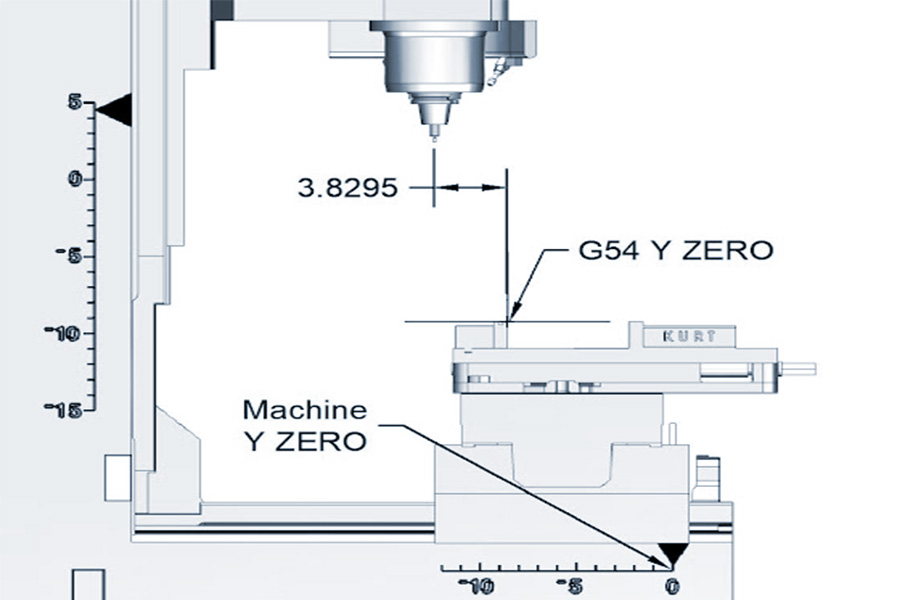

How to set the coordinate system commonly used in five-axis machining?

1.Determine the machining zero point position

- Touch the workpiece surface with a tool setting instrument or probe to find the position you want to use as the zero point (such as the corner or center of the workpiece).

- When JS processes turbine blades, our engineers usually set the center of the bottom surface of the blade root as the zero point.

2.Input data to the control system

- Select G54 (or G55, G56) on the machine tool operation panel and fill in the measured zero point coordinates (X/Y/Z values).

- Note: If it is a five-axis machine tool with a turntable, you must also enter the initial angle value of the rotation axis (A/C axis).

3.Deal with the influence of the rotation axis

- During 5 axis machining, the workpiece may be flipped by the turntable, causing the zero point to move.

- Solution: Bind the coordinate system and the rotation axis in the programming software and let the system automatically compensate for the position.

4.Verify the coordinate system

- Run the program empty to observe whether the tool is close to the workpiece as expected. Don't cut it directly!

- Our tips: Raise the Z axis 50mm before trying again, and don’t worry if it crashes.

5.Switching between multiple coordinate systems

If the same workpiece needs to be processed in multiple areas, after setting G54, repeat the above steps to set another zero point for G55.

Applicable scenarios: For example, when processing cavities and locating holes on a mold at the same time, using different coordinate systems saves the need to re-calibrate the tool.

5-axis vs. 3-axis: How to distinguish?

1.Core difference

3 axis machine tools are like precise coordinate painters, and can only move tools in three linear directions (front and back, left and right, and up and down) of X/Y/Z. On this basis, 5 axis machine tools have two more rotation axes (usually marked as A/B axes), which is equivalent to equipping the tool with mechanical joints, allowing it to tilt freely during cutting.

| Comparing dimensions | 3 axis machining | 5 axis machining |

| Movement axis | X/Y/Z linear axis. | Add A/B rotation axis. |

| Processing complexity | Flat/simple surface. | Complex three-dimensional structures such as turbine blades. |

| Human intervention needs | Each side of the processing requires manual flipping of the workpiece. | Fully automatic multi angle cutting. |

| Accuracy error | ±0.1mm. | ±0.02mm. |

| Typical cost | $70,000-$210,000. | $420,000+. |

2.Applicable scene selection

Choose 3 axis: Suitable for limited budget (equipment price is 30%-70% cheaper), processing flat/shallow groove parts (such as mobile phone shells), or small batch production (no complex programming).

Choose 5 axis: When encountering deep cavity structures (such as engine cylinder blocks), special-shaped curved surfaces (denture implants), or ultra-high precision requirements (aerospace bearings), five-axis can complete the process that traditional machine tools require 5-6 clampings in one go.

3.Efficiency and cost balance

Although the purchase price of 5 axis machine tools is higher, its continuous processing characteristics can save more than 60% of working hours when processing complex parts such as automotive molds. For example, to manufacture aluminum alloy turbocharger impellers, three-axis requires 7 days + 3 manual calibrations, while five-axis only takes 2 days to complete fully automatically.

Which industries rely most on 5 axis CNC processing technology?

1.Medical industry

- Demand characteristics: Human implants (such as joints and bone plates) need to fit the patient's anatomical structure perfectly, with precision requirements comparable to the thickness of a hair (tolerance ±0.01mm), and the materials need to be biocompatible and have a smooth surface.

- JS's 5 axis CNC machining services advantage: We can process complex surfaces in one go, and provide full-process processing from titanium alloy joints to porous bone implants based on the personalized needs of patients. A single clamping can complete the engraving of special-shaped surfaces, avoiding multiple adjustments in traditional processes.

- Typical applications: Ball and socket structure of artificial hip joints, porous surface of spinal fusion devices, and precision channels of minimally invasive surgical instruments.

2.Electronics industry

- Pain point solution: Electronic products go for thinness and lightness, but small components such as heat sinks and chip interfaces require extremely high precision requirements (e.g. the tolerance of mobile phone SIM card slots should be less than 0.05mm).

- JS technical specifications: Aluminum shells' curved chamfers and internal card slots can be machined in parallel by our five-axis machine tools, and even circuit board positioning holes are engraved on the metal surface to avoid multi-process connection mistake.

- Sample products: Laptop integrated metal body, 5G base station radiator, semiconductor wafer carrier.

3.Customized processing

- Subverting tradition: In the past, manual proofing took 2-3 weeks. 5 axis CNC can transform complex designs (such as gear set prototypes) into physical objects within 48 hours, and materials ranging from plastic to carbon fiber can be handled.

- JS's core value: Our engineers can quickly verify the feasibility of special-shaped structures. For example, automobile clay models are directly upgraded to testable metal functional parts, shortening the development cycle by 60%.

- Typical cases: One-time molding of drone folding joints and precise restoration of customized denture occlusal surfaces.

4.Aerospace

- Ultimate requirements: Aircraft engine blade weight reduction of 1 gram, the whole machine saves 2 tons of fuel per year. Satellite brackets must be both lightweight and radiation-resistant, and the topological optimization structure is as complex as a vascular network.

- 5 axis CNC machining service threshold: We have passed AS9100 aviation certification and can provide micron-level processing for key components such as rocket engine fuel chambers, and even achieve milling instead of grinding, directly milling a mirror effect (Ra≤0.1μm).

- Products processed by our company: Spacecraft fuel nozzles (accuracy up to 1 micron), wing spoiler curved airfoil, rocket engine nozzle cooling channel.

How to reduce the cost of 5-axis machining?

1.Pay attention to the price of machine tools

The price of five axis CNC machine tools is influenced by multiple factors, with regular models typically costing hundreds of thousands of dollars, while high-end configurations may exceed millions of dollars. This price fluctuation mainly depends on brand positioning, processing range, technical configuration, and degree of automation.

Taking medium-sized equipment as an example, the basic model quotation is concentrated in the range of 100,000 to 200,000 US dollars, but if it is necessary to expand the processing stroke or add intelligent monitoring modules, the overall cost may double.

It is worth noting that companies in the 5 axis CNC machining UK field tend to choose models equipped with thermal compensation systems, which can automatically correct deformations caused by environmental temperature and are particularly suitable for high-precision mold manufacturing.

2.Core cost composition

Bed of machine tool casting is approximately 25%-30% of the total investment. This part has a tendency to adopt resin sand casting process in order to exhibit improved shock absorption capability. However, as far as what really affects the cost is concerned, it is tied to the core component of the motion control system. This imported precision roller guide rail, could be three times the price of the domestic one, but can keep repeat positioning accuracy in ±0.003mm stable.

For those who are currently considering 5 axis cnc machining center for sale in recent times, please take note. The premium rate of second-hand equipment for direct-drive rotary table equipped equipment is usually more than 15%, as it can rotate to 800°/s, which greatly improves the efficiency of surface processing.

3.Selection of software system

The control system with adaptive machining function is about 20% more expensive than the basic version, but it can automatically optimize cutting parameters and extend the tool life by 30%. If an automatic tool changing system (such as a 24-station tool magazine) is added, the equipment cost will increase by 80,000-120,000 US dollars, but this type of configuration can shorten the tool changing time for mass production to less than 10 seconds.

According to statistics from the British Manufacturing Association, the cost of adding a robot arm to a 5 axis device with a modular design is 40% lower than directly purchasing the whole machine.In the actual operation of our company, the five-axis machine tool can improve the overall efficiency by more than 45% by reducing the number of clamping times.

For example, when machining aircraft engine blades, the traditional process requires five processes, while the five-axis equipment can be completed with a single clamping, which not only saves 70% of the auxiliary time, but also controls the scrap rate below 0.05%. For precision parts with a unit price of more than 1,500 pounds, this means that nearly 10,000 pounds of material losses can be avoided for every 1,000 pieces produced.

4.Cost control suggestions

- Component mix and match strategy: Lightweight aluminum alloy is used for non-load-bearing structures, and key transmission components retain imported configurations.

- Seize the opportunity to purchase: Some British equipment manufacturers launch limited-time discounts at the end of the quarter. In a recent 5 axis CNC machining center for sale event, the price of the standard model has dropped by 12%.

- Phase-based intelligence: Initially configure the basic sensor system, and gradually connect to the Internet of Things platform in the later stage.

- Regional collaboration model: Select several suitable 5 axis cnc machining near me companies to jointly build a technology center and share the right to use high-value equipment.

How to choose the right 5 axis CNC machining service?

1.Look at the equipment hardware

Directly ask the manufacturer what brand of machine tools (such as Germany's DMG and Japan's Mazak) the equipment is used for, and how many years the equipment has been used. As an established manufacturer, we usually have more than 10 5 axis CNC machining centers, which can accept large orders and urgent orders at the same time.

Focus on checking the spindle speed (at least 12,000 rpm) and positioning accuracy (preferably within ±0.005mm). The machine configurations for processing aluminum alloy and titanium alloy are very different.

2.Test technical strength

Requires to see similar parts processing cases, such as joint surfaces of medical devices or aviation impellers. We will provide a video of the processing process, and even let you see how our workshop handles the ultra-precision tolerance of ±0.01mm on site.

3.Compare service flexibility

Test response speed: Send a simple drawing to see how long it will take to get a quote, and JS's professional team will feedback the process plan within 24 hours.

Ask for the minimum order quantity. We also provide small and large batch processing customization services. Even if the drawings are complex, we can respond within 24.

4.Calculate the comprehensive cost

It is necessary to check the cost details provided by the supplier, and pay special attention to the number of quality inspection processes and whether there are additional charges for tooling design.

Confirm hidden costs before signing a contract: For example, how much extra money is required for special materials (such as PEEK plastic), and whether there is an additional charge for modifying drawings.

Summary

5 axis CNC machining technology does have advantages in manufacturing complex parts, especially in the precise control of part details and surface treatment effects. Although it costs more to buy equipment than ordinary processing equipment at the beginning, it is actually quite cost-effective after using it for a long time. The processing time can be shortened a lot, the qualified rate of the parts produced is also high, and there are fewer cases of rework and repair later, and the overall cost can actually be reduced.

In the process of upgrading the manufacturing industry, many companies encounter technical difficulties that are actually related to processing accuracy. Companies in need can contact JS company. We provide free processing solution consultation and quickly send you customized production suggestions!

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.What does 5 axis linkage specifically mean?

Five-axis linkage refers to the synchronous movement of the X/Y/Z linear axis and the A/B rotary axis, so that the tool can continuously maintain the optimal cutting angle and achieve single clamping and forming of complex curved surfaces.

2.How much more expensive is the equipment than the 3 axis?

The price of five-axis equipment is usually 3-5 times that of three-axis, about 210,000-700,000 US dollars, depending on the configuration accuracy.

3.Why is it suitable for processing impeller blades?

5 axis linkage can adjust the tool angle, complete the complex curved surface and thin wall processing of the impeller in a single clamping, ensure accuracy and avoid interference.

4.What skills do operators need?

5 axis operation requires the ability to master CNC programming, system debugging, tool management, collision prevention and 3D drawing analysis.