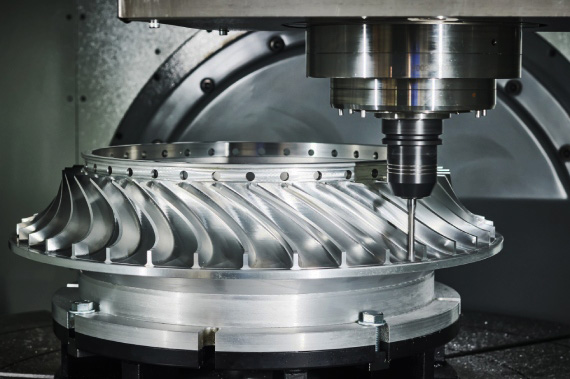

A piece of hard metal can be turned around and adjusted flexibly under the control of precision machine tools. The cutting tool can cut from any side you want, and the cutting is very accurate. Just like this, little by little, the metal finally becomes a precision aircraft part, a medical nail, or even an exquisite sculpture.

This is the power of 5 axis CNC machining! It represents the top level of modern manufacturing in making complex shapes, making them precise, and making them quickly.Next, let’s take a closer look at what the 5 axis CNC machining service can do.

What is 5 axis CNC machining?

Simply put, 5 axis CNC machining is a more advanced CNC milling technology. Like the three-axis and four-axis milling machines we are familiar with, it uses high-speed rotating tools to cut the material into the desired complex shape little by little like carving.

The most common CNC milling machine in the factory now mainly relies on the tool to move in three linear directions (front and back, left and right, up and down) to work. This 3 axis machine tool is very useful for making parts with simple structure and low cost, but its capacity is limited, and it cannot make some complex shapes.

5 axis CNC machining is much more powerful. Our operators first use CAM software to translate the complex machining actions into detailed instructions (the so-called G-code) that the machine tool can understand based on the design drawings of the parts.

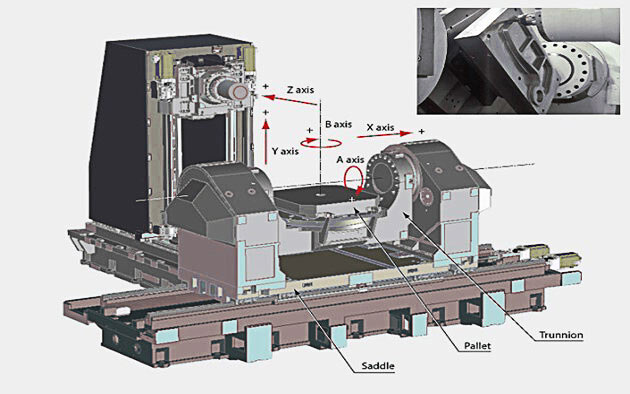

After receiving these instructions, 5 axis CNC machining can move the tool in those three linear directions and rotate the workpiece itself or the tool by two additional angles. This is equivalent to having two more flexible joints during machining, allowing the tool to contact the workpiece from almost any direction.

What are the key advantages of 5 axis CNC machine tools?

Today, more than half of the precision parts processing needs involve five-sided processing, which directly promotes the popularity of five-axis machine tools in manufacturing workshops. Compared with traditional three-axis processing, 5 axis CNC machining services show significant advantages in multiple dimensions:

1.Single clamping to complete complex processing

5 axis machine tools have five directions of movement (three linear axes plus two rotary axes). The biggest convenience is that you only need to clamp and fix the workpiece once, and the machine tool can take care of all the remaining complex processing steps by itself, and directly make the finished parts.

This is completely different from 3 axis machine tools. When making complex shapes, 3 axis machine tools often require you to remove the workpiece, turn it over or change the angle to re-clamp it several times.

The result is: Making complex parts faster and cheaper, avoiding the errors caused by multiple clamping, and the finished product is more reliable.

2.Short tool application and excellent surface quality

5 axis machine tools allow the workpiece or tool to turn the angle flexibly, bringing the processing area closer to the spindle.

Professional advantage: You can use shorter and stronger cutting tools. Short tools have higher rigidity and natural frequency, which can effectively suppress cutting vibration.

Direct effect: Greatly improve the surface finish of the workpiece (lower Ra value), reduce the need for subsequent polishing, and achieve higher cutting parameters (feed, cutting depth), while extending tool life.

3.Processing delicate and difficult parts

Because the 5 axis machine tool is more flexible (the 5 axes can move in coordination), it is inherently more accurate than the three-axis machine tool.

Core capabilities: This not only means smoother surface of the parts, but more importantly, it unlocks the ability to manufacture highly complex geometric parts. Such parts (such as impellers, integral blades, complex mold cavities, biomedical implants) are often impossible to process with three-axis machines or have extremely low processing efficiency and difficult to ensure accuracy.

4.Ability to accept more types of orders

Five-axis processing capabilities have become a key entry ticket to high-precision manufacturing fields such as aerospace, high-end medical equipment, precision molds, and energy equipment. It can process parts that cannot be completed economically and efficiently or even cannot be achieved at all by relying on 3 axis or 3+2 positioning processing.

What are the specific steps of 5 axis machining from programming to finished product?

5 axis CNC machine tools, like other CNC machine tools, work under the command of computers. It relies on computer programming to accurately control how the tool moves and how the workpiece moves (or turns). The whole process can be divided into three steps:

Step 1: Draw a digital model of the part

Our engineers first use professional 3D CAD software to carefully draw the parts to be made on the computer. This digital model is the basis for all subsequent work.

Step 2: Turn the design drawing into an operating manual for the machine tool

The drawn CAD model will be imported into the CAM software.

The role of CAM software is very critical:

- It automatically plans the route that the tool should take according to the shape of the part.

- It translates complex machining actions into a language that the machine tool can directly understand, G code.

- This G code tells the machine tool's tool how to move in the three linear directions of X, Y, and Z. It also simultaneously directs the worktable (or spindle head) to rotate and tilt around the A axis and B axis (or other rotation axis combination).

The key is here: The movement of the five axes (X, Y, Z linear axes + A, B rotary axes) is synchronized and coordinated, so that the tool can cut complex shapes at the best angle.

Step 3: The machine tool is constructed according to the drawing and clamped once

The generated G code is input into the control system of the 5 axis CNC machine tool.

The machine tool moves strictly according to the instructions: The tool moves flexibly in space, and the workpiece is constantly adjusting the angle.

The biggest advantage is: Using the freedom of these five axes, the workpiece only needs to be clamped and fixed on the machine tool once, and the five faces or even more complex shapes can be processed in place.

The result is:

- Greatly save time, eliminating the trouble of repeated disassembly and repositioning.

- Reduce costs, reduce labor and machine time.

- The parts are made more accurately, avoiding the errors that may be caused by multiple clamping.

Note: The specific speed and rotation method of the machine tool will vary depending on the structure type (such as turntable rotation or swing head rotation) and configuration of the machine tool.

Why choose 5 axis machining instead of other machining?

Choosing between 5 axis machining and other technologies does require careful consideration. Don't worry, it will be much easier to choose if you understand their core differences. Let's focus on comparing the two most common "rivals":

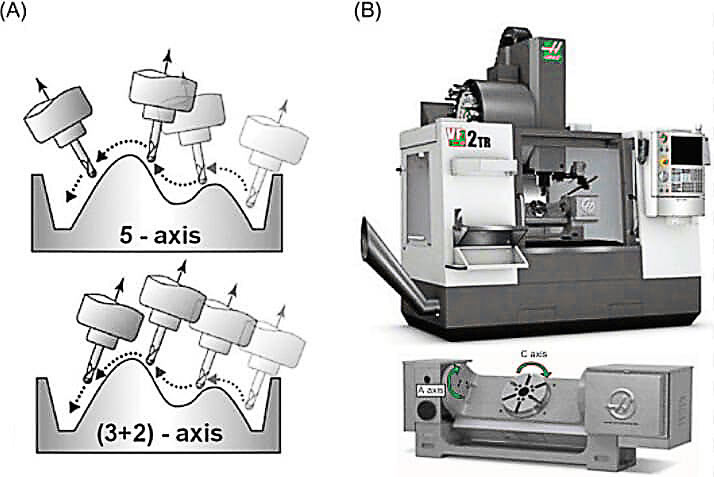

1. 5 axis vs. 3+2 axis (indexing machining)

Many people are easily confused: Although the names have five axes, the working methods are very different!

5 axis (true five-axis):

Core features: During machining, the 5 axes (X, Y, Z linear axes + A, B/C rotary axes) are moved simultaneously, continuously, and coordinated (professionally called RTCP/tool tip following function). The tool can adjust the angle while moving, and cut complex surfaces quite smoothly.

Advantages:

- Faster speed: No pause, one-step, suitable for continuous machining of complex surfaces (such as impellers, turbine blades).

- Better surface quality: Continuous movement brings smoother surfaces.

- Can do more complex work: Really handle those complex spatial surfaces.

- The fixture is simpler and saves money: One clamping is enough, and the fixture cost is low.

3+2 axis (positioning five-axis/indexing processing):

Core features: It is essentially an advanced version of 3 axis processing. It first rotates the workpiece to a fixed angle with two rotating axes (A/B) and locks it, and then uses only three linear axes X, Y, and Z to mill like an ordinary 3 axis machine tool. After completing one angle, it rotates to the next angle (indexing) and then locks the processing. The movement is step-by-step.

Advantages:

- Programming is relatively simple: It can be understood as adding angle positioning to the 3 axis program.

- Suitable for processing planes/simple inclined surfaces: For example, processing multiple planes or holes in different directions on a workpiece (such as casings and box parts).

- The cost of machine tools is usually lower: The requirements for machine tool motion control are not so high.

Disadvantages:

- Slow speed: Every time you change the angle, you have to stop, turn, lock, and restart.

- Cannot make complex continuous surfaces: The angle is locked, and the tool can only cut vertically or at a fixed angle.

- There may be joints on the surface: The junction of different angle processing areas may not be perfect.

5 axis vs. 3+2 axis

| Characteristic | 5 axis | 3+2 axis |

| Form of exercise | Coordinated motion of five axes simultaneously and continuously. | First locate the angle (lock), then perform three-axis machining. |

| Speed | Fast (continuous without pause). | Slow (requires division pause). |

| Programming complexity | High (requires professional CAM, considering interference). | Medium low (can be seen as 3 axis+angle). |

| Fixture cost | Usually low (single clamping). | Possible high (considering multi angle support). |

| Equipment cost | Usually higher. | Usually lower. |

2. 5 axis CNC machining vs. 3D printing

Fundamental difference:

| Category | 5 axis CNC machining | 3D printing |

| Manufacturing principle | Subtractive manufacturing (cutting and forming). | Additive manufacturing (layer by layer stacking). |

| Core Differences | Dependent on the physical contact of cutting tools for cutting, limited by tool accessibility. | No tool interference restrictions, free construction of complex geometric shapes. |

5 axis CNC machining:

Advantages:

- High material strength: Directly using engineering materials (metal, plastic blocks), the performance of the machined parts is the performance of the material itself, which is usually better than that of additively manufactured parts.

- Top precision and finish: Especially dimensional accuracy and surface finish (Ra value), far exceeding most 3D printing. All sizes (from small parts to large workpieces). The mini 5 axis cnc machining center is particularly good at micro-machining of small parts with high precision and complex curved surfaces.

- Mature and efficient (batch): Suitable for medium to large batch production, fast speed and stable quality.

Disadvantages:

- Design restrictions: The tool can only be processed where it can touch, and complex cavities and extremely complex topological structures may be difficult to make or require special processes (such as EDM). The mini 5 axis cnc machining center can process relatively small workpieces.

- Material waste: Cutting will produce waste (chips).

- Fixture/programming: Clamping and complex programming are required.

Advantages:

- Design freedom: Complex structures (including internal cavities, integrated assembly) can be manufactured without tool restrictions.

- Agile production: No fixture required, suitable for prototype/small batch customization, material utilization rate exceeds 90%.

- Efficient iteration: No mold constraints, fast verification of design changes.

Disadvantages:

- Performance limitations: Interlayer bonding is weaker than forgings, there is anisotropy, and fatigue performance is low.

- Limited precision: Post-processing is required to improve surface quality (sandblasting/CNC finishing), large size is prone to warping and deformation.

- Poor economic efficiency: The cost of metal printing equipment exceeds $700,000, the hourly printing fee is nearly a thousand dollars, and the time required for a single piece is too long (for example, aerospace parts generally exceed 24 hours).

Choose based on core needs:

- To make high-strength, high-precision, high-surface quality metal or plastic parts, 5 axis linkage is the first choice.

- For parts with multi-directional planes/holes, 3+2 axis may be more economical and efficient.

- For extremely complex designs, small batches, prototypes, or internal cavity structures that cannot be made by traditional methods, 3D printing is very suitable.

- For large-scale production, five-axis or traditional 3 axis/multi axis are usually more efficient and less costly.

Which parts need to use a 5 axis CNC machining center?

1.Complex curved surface parts

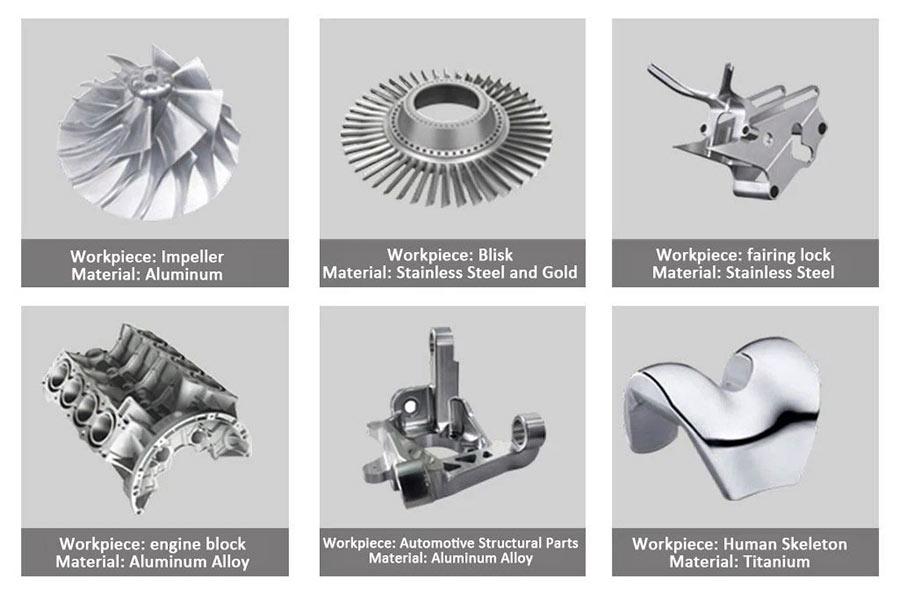

Typical representatives: Blades, impellers, integral blade disks of aircraft engines/gas turbines, cavities of high-precision injection/die-casting molds (such as automotive covers, consumer electronics shell molds), and complex human implants.

Solution:

- Solve tool interference problems such as deep cavities and negative angles. By rotating the worktable or swinging the spindle head, the tool can always approach the processed surface at the best angle.

- 5 axis linkage (moving 5 axes at the same time) can make the tool center point or tool tip point move accurately along the complex curved surface path, which can obtain better surface finish and eliminate step residue.

- Surface processing is completed in one clamping to avoid repeated positioning errors.

2.Multi-directional feature parts

Typical representatives: Complex engine cylinder block/cylinder head, gearbox housing, precision medical device housing/bracket, aerospace structural parts (such as wing ribs, joints).

Solution:

- By rotating the worktable, any surface of the workpiece can be easily adjusted to a position that is convenient for processing, and multi-angle holes/slots/planes can be processed.

- Maintain the position accuracy of cross-surface features (±0.01mm level).

- Save more than 50% of clamping and adjustment time.

3.Thin-walled parts that are easy to deform

Typical representatives: Long spars and wing beams on aircraft, thin-walled turbine shells, ribs in deep cavity molds, and heat dissipation shells of electronic equipment.

Solution:

- Adjust the cutting angle of the tool relative to the workpiece, so that the main cutting force can be directed to the direction of better workpiece rigidity.

- Use shorter and more rigid tools to improve processing efficiency and quality.

- Side milling process reduces the risk of deformation by more than 70%.

4.Ultra-high precision components

Typical representatives: Precision optical lens molds (especially aspherical surfaces), high-precision gears, and key load-bearing components of aerospace.

Solution:

- For extremely precise parts, even micron-level repeated positioning errors are unacceptable. 5-axis machining can eliminate the error accumulation of multi-process clamping (error chain <3μm).

- 5 axis cnc machining center is the only one that can efficiently and accurately complete more than 20 processes such as roughing and finishing, surface/hole system processing, etc.

- Meet the requirements of mirror and aspheric precision below Ra0.4.

How to shorten the machining cycle of 5 axis machining?

1.Optimize programming and tool path

Use intelligent CAM software more often during programming to simplify the tool path as much as possible and reduce the time of idle tool running. For example, 5 axis CNC machining UK will use adaptive cutting function to keep the tool at full load, and the efficiency will be directly increased by more than 20%.

2.Upgrade fixture design

Use modular fixtures or zero-point positioning system, and there is no need to adjust the position repeatedly when changing workpieces. For example, 5 axis CNC machining near me companies always have standardized tooling plates, and the clamping time can be compressed to less than 5 minutes, which is twice as fast as the traditional method.

3.Adjust machining parameters

Boldly increase the feed and speed according to the material characteristics. JS's actual data shows that when cutting aluminum alloy with dynamic milling technology, the feed speed can be increased to 1.5 times the normal speed without damaging the tool, and the machining cycle is naturally shortened.

4.Reduce the number of tool changes

Plan the process in advance and concentrate the same type of processing. We have conducted tests and found that by separating roughing and finishing into batches, the overall efficiency increased by 18% and the tool life was extended.

What are the challenges of 5 axis CNC machining? How to solve them?

1.Difficult programming and low fault tolerance

Difficulty: Control the XYZ axis + dual rotary axis movement at the same time, avoid the workpiece/fixture movement, and the path planning is comparable to a three-dimensional maze, which is easy to get confused.

Countermeasures:

- We usually use professional CAM software to automatically generate tool paths, which has built-in anti-collision detection function.

- Computer empty run simulation: The program must be verified by 3D cutting simulation.

- Disassembly and processing steps: 3 axis rough machining + 5 axis finishing of key parts.

2.High pressure on equipment investment

Current situation: The price of a new imported five-axis CNC machining center is generally more than 2 million, and domestic models also start at 800,000.

Purchase strategy:

- Second-hand market gold rush: Pay attention to 90% new equipment from regular channels, and the price can be cut by 30%-50% (focus on checking the accuracy of the turntable).

- Business matching principle: Give priority to high value-added orders such as medical/aerospace, and don't use 5 axis machine tools to do three-axis rough work.

- Long-term economic account: Complex parts can be processed in a single clamping, and the cost of saving 3-5 processes should be taken into account.

3.High risk of collision

- Tool inspection is required: Use tool setting instrument to confirm tool length (error within ±0.01mm).

- Test run procedure: New program should be run at 10% speed first, and put your hand on the emergency stop button to wait.

- Hardware protection: Optional laser anti-collision system, automatic shutdown in 0.1 seconds when encountering obstacles.

4.Precision control

Three keys to precision guarantee:

- Monthly inspection: Use ballbar to detect the five-axis linkage accuracy of machine tools.

- Real-time compensation: Turn on the thermal deformation compensation function (focus on spindle temperature control).

- Tool management: Equipped with wireless probe to automatically update tool length data.

Special reminder: Recently, a large number of modified 5 axis CNC machining center for sale have appeared in the second-hand market. It is recommended to focus on checking the wear of the worm gear of the rotary table, and don't be pitted by refurbished machines. It is recommended for novices to choose models with RTCP function, which can automatically compensate for the tool offset caused by the rotating axis.

Summary

5 axis CNC machining is the key technology to unlock the manufacturing of complex parts. It accurately transforms engineers' complex ideas into reality through the exquisite linkage of five axes (three translations + two rotations).

As a professional 5 axis CNC machining center manufacturers, JS can not only provide stable and reliable equipment, but also customize a complete set of processing solutions according to customer needs. From mold manufacturing to precision parts processing, we have helped more than 300 companies shorten delivery time, and truly achieved the hard-core strength of complex parts and one-time molding.

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.How does a 5-axis machine tool move the tool?

The 5-axis machine tool uses the XYZ linear axis and two rotary axes to enable the tool to move flexibly in five directions and at multiple angles, and efficiently process complex surfaces.

2.What is the role of the rotary axis?

The rotary axis adjusts the angle of the tool or workpiece to achieve multi-faceted processing, reduce repeated clamping, and improve the processing accuracy and efficiency of complex parts.

3.Does 5-axis processing require special programming?

Yes, multi-axis CAM software programming is required to accurately control the tool angle and rotary axis linkage, avoid collisions and optimize the processing path to ensure efficient forming of complex surfaces.

4.How to avoid collisions between the tool and the workpiece?

Use CAM software to simulate the path, set the safety area and optimize the tool angle and feed speed, and monitor the motion trajectory of the rotary axis in real time to avoid interference.

Resource