Don't underestimate the pinion gears, they are a vital role in the mechanical world! The operation of various large equipment is inseparable from the precise coordination between the pinions. They are not big, but they play a big role in transmitting power, adjusting speed and ensuring precision.

It is not easy to turn an ordinary piece of metal material into such a small part with a small size, accurate tooth shape, smooth surface, and can withstand high-intensity work. Processing pinions requires us to constantly break through the processing limits. In a very small space, we must ensure the absolute accuracy of the gear shape, make the surface smooth and wear-resistant, and ensure that the performance of the material itself is excellent enough.

This article will talk about what key steps a piece of raw material goes through before it is finally transformed into a reliable and precise pinion gear. We will disassemble the entire process from raw materials to finished products step by step.

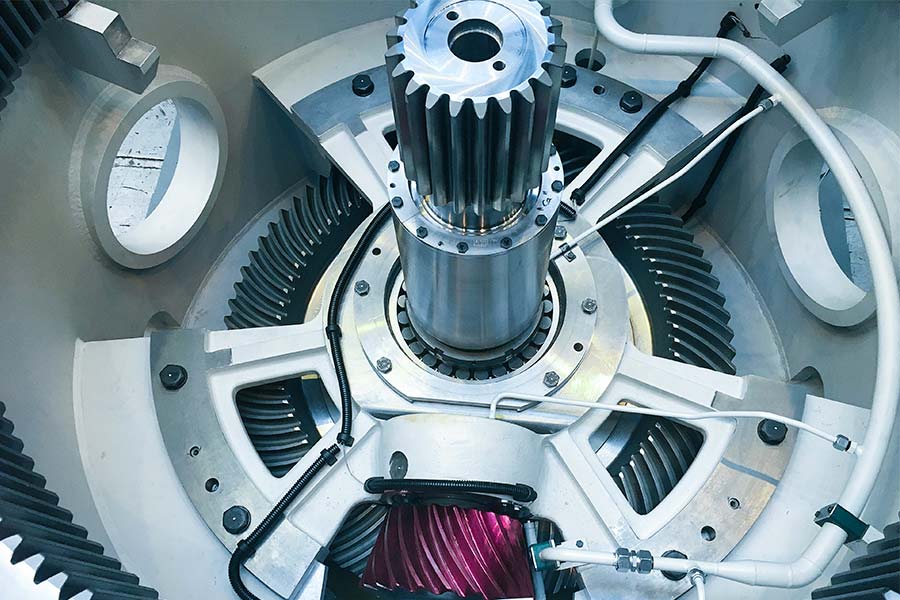

What is pinion machining?

Pinion machining is actually the process of manufacturing a small wheel with teeth. This small wheel (scientific name is pinion) is usually the key part responsible for transmitting power in the machine, and it must work closely with the larger gear.

The core of processing is to use precision machine tools to cut out very precise teeth on metal or high-strength materials little by little, just like carving. Why is it so particular? Because if the shape and angle of the teeth are even slightly different, the whole machine will be noisy, wear quickly, or even get stuck when it is running. It can be said that it is an important link to ensure the quietness, efficiency and long life of the machine. It is indispensable for places like automobile gearboxes and precision instruments.

What steps are required for pinion machining?

1. Prepare the blank

First, prepare the raw materials of the pinion. According to the designed size and shape, cut the metal bar (commonly used are various steels) into sections, or prepare pre-forged or cast blanks that are close to the shape of the pinion.

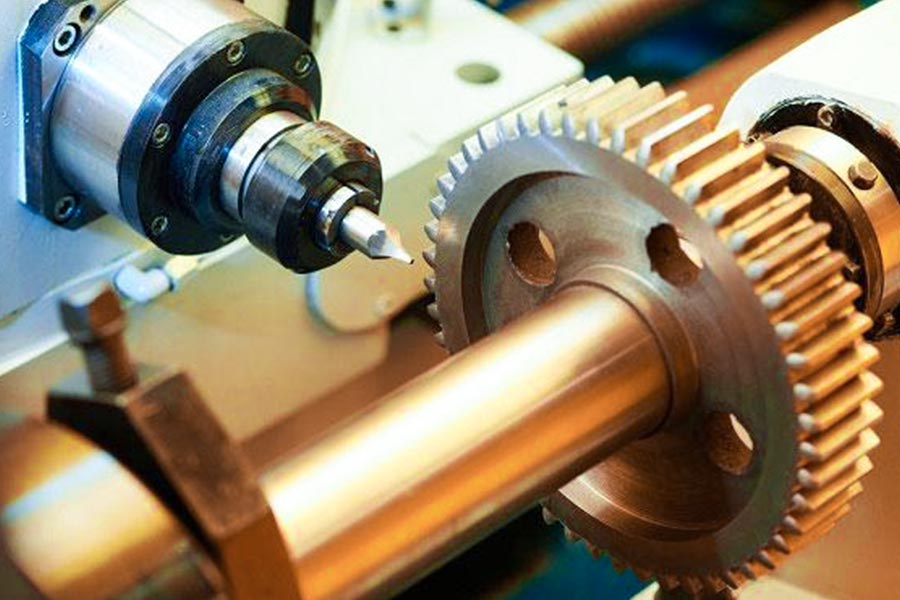

2. Turning the shape

Fix the blank to the lathe, and use the turning tool to process the outer circle, inner hole, and two end faces of the blank to achieve the precise size and surface finish required by the drawing. This step is mainly to determine the basic skeleton shape of the pinion.

3. Tooth processing

This is the core step of pinion machining, which is specially used to process the teeth of the pinion. Install the machined blank on the gear hobbing machine or gear shaping machine.

- Gear hobbing: Use a rotating hob shaped like a worm or comb, which rotates itself and moves slowly along the blank to gnaw out the tooth groove. It is efficient and most commonly used.

- Gear shaping: Use a gear-shaped gear shaping cutter that reciprocates up and down to shovel out the tooth shape on the blank one by one. It is suitable for processing internal gears or gears close to steps.

This step determines the basic shape, number, size and position of the pinion teeth.

4. Heat treatment

The pinion that has just had its teeth cut is usually not hard enough, and it will wear and deform quickly if used directly. Therefore, it must be heat treated and put into a special furnace for treatment.

Common heat treatment methods are:

| Heat treatment process | Main purpose and effect | Applicable scenarios |

| Carburizing and quenching | Allow carbon elements to infiltrate the surface of the gear and then quench it. The surface becomes very hard (HRC 58-62), while the heart maintains toughness. | Automotive and engineering machinery gears that require high wear resistance and impact resistance. |

| Induction hardening | Allow carbon elements to infiltrate the surface of the gear and then quench it. The surface becomes very hard (HRC 58-62), while the heart maintains toughness. |

Medium to large gears require hardening in specific areas.

|

| Quenching+high temperature tempering |

Whole heating quenching followed by high-temperature tempering. Obtain good comprehensive mechanical properties (balance of strength and toughness).

|

Gears that do not require high surface hardness, but require high overall strength. |

| Nitriding | Heat in a nitrogen-containing atmosphere to allow nitrogen to infiltrate the surface and form a hard layer. High hardness, minimal deformation, and good corrosion resistance. | Precision instruments and aviation gears require stable dimensions and wear resistance. |

5.Gear grinding

After heat treatment, the pinions will inevitably have extremely small deformations, and the accuracy of gear cutting is not enough for occasions with extremely high precision requirements. At this time, the gear grinding machine is needed. It uses a high-speed rotating, extremely precisely shaped grinding wheel to grind each side of the teeth very accurately and smoothly little by little.

This step is the key to ensure that the pinions can transmit power quietly, smoothly and efficiently. Low noise, long life and accurate transmission all depend on it.

The accuracy level that can be achieved by gear grinding is usually much higher than that of gear cutting:

| Common accuracy levels (ISO 1328) | Main application scenarios | Characteristic |

| Level 5-6 | High precision machine tool spindle, aircraft engine, precision reducer. | Require extremely low noise, extremely high transmission stability, and long service life. |

| Level 7 | Automobile gearbox (high gear), industrial robot joints, precision instruments. | Require low noise, high transmission efficiency, and long lifespan. |

| Level 8 | General industrial gearboxes, automotive gearboxes (mid low gears), and construction machinery. | Good cost-effectiveness, meeting general industrial needs. |

| Level 9 and below | Agricultural machinery, low requirement transmission. | Low cost, suitable for occasions with low requirements for noise life. |

6. Finishing

After the pinion machining is basically completed, some minor finishing work may be required:

- Deburring: Our operators usually use manual or machine to carefully remove the small burrs and burrs left over from the edge and root of the gear to prevent scratching or affecting assembly.

- Cleaning: Clean the pinion thoroughly to remove oil stains, metal debris, etc. stained during the processing.

- Rust prevention: According to customer requirements, we may also apply anti-rust oil or do other anti-rust treatments to prevent rust during storage or transportation.

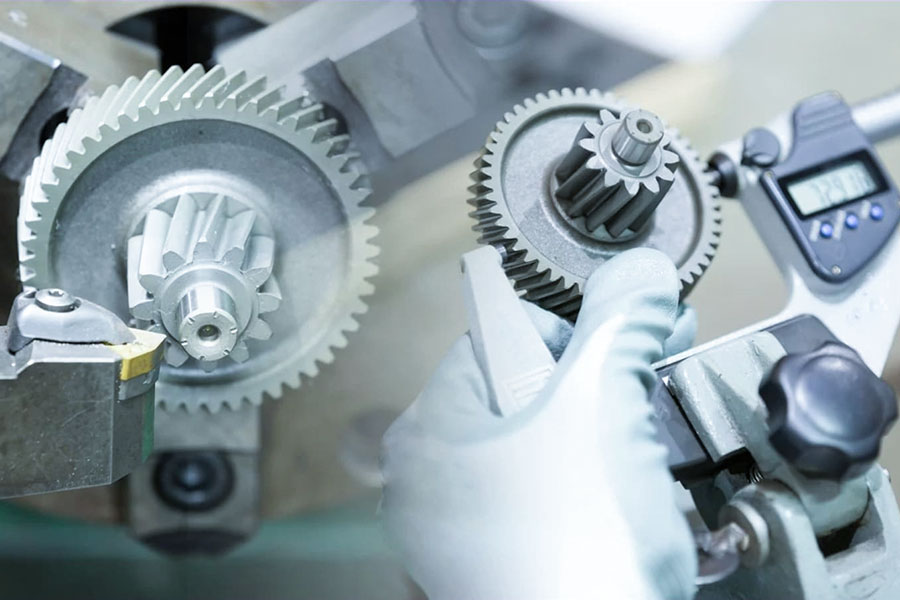

7. Final inspection

After the pinion is thoroughly cleaned, it will enter a strict inspection link. Use various precision measuring tools and instruments to measure every detail such as the shape and contour of the teeth, the distance between teeth, the inclination of the tooth surface, the smoothness of the surface, etc., to ensure that it fully meets the stringent requirements of the design drawings.

Only pinions that pass all inspections can be considered qualified products and are allowed to be installed in the machine for work.

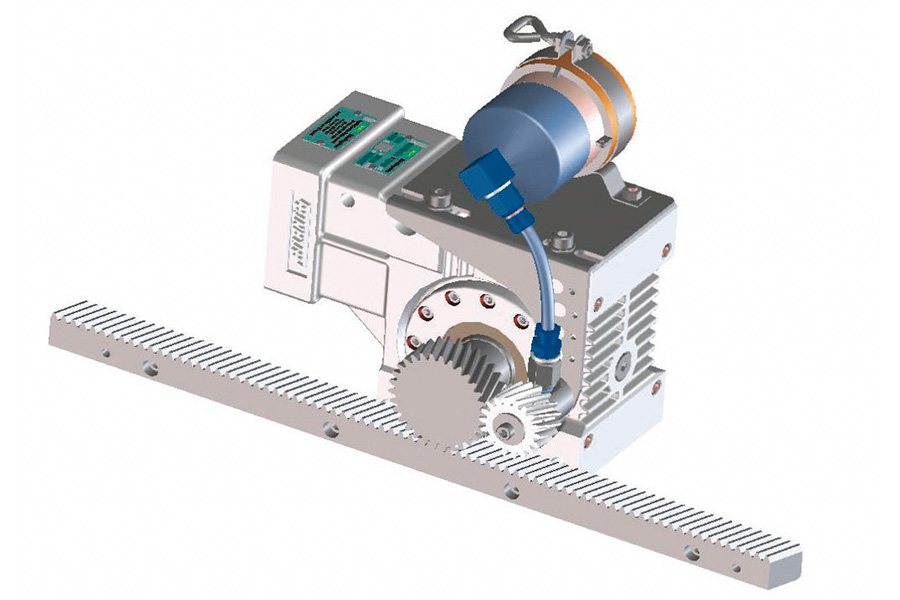

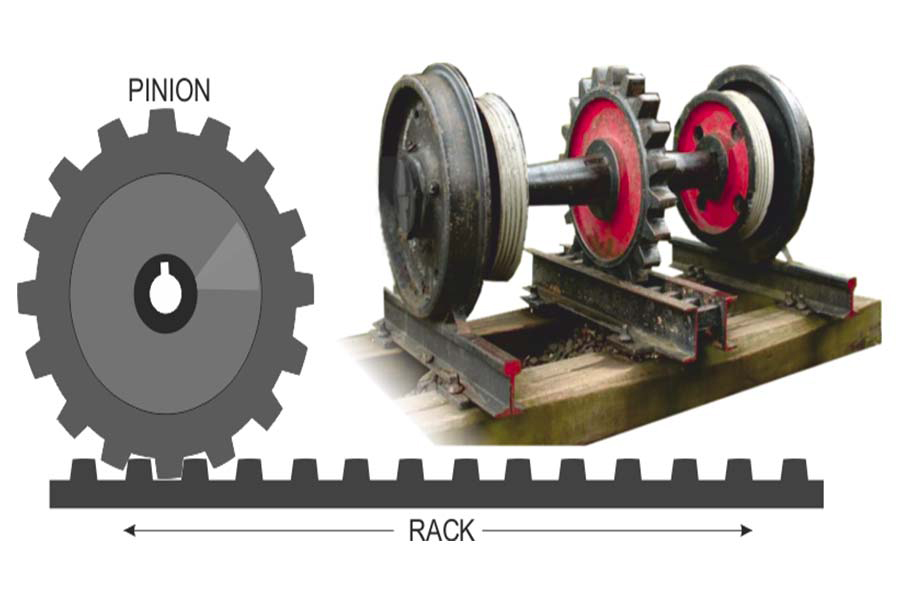

How do racks and pinions work together?

1. Perfect fit

The pinion teeth and the tooth grooves on the rack are specially designed to match perfectly (usually involute tooth shape). The pinion tooth protrusion fits firmly into the rack groove, just like a key in a lock.

2. Core action

- The first case: the pinion turns and the rack moves in a straight line. When the pinion is driven by the motor to rotate, its teeth push the corresponding tooth grooves on the rack. Because the rack itself is restricted to move in a straight line (such as when mounted on a guide rail), it is driven by the pinion to move forward or backward in a straight line.

- The second case is that the rack moves in a straight line and the pinion turns. If an external force directly pushes the rack to move in a straight line, the teeth of the rack will push against the teeth of the pinion, forcing the pinion to rotate around its axis.

3. Key node coordination

The teeth must be the same size: This is a hard requirement! The size specification (module) of each tooth on the pinion and rack must be exactly the same.

The inclination angle of the teeth is consistent: the inclination angle of the side of the teeth must also be the same. This determines whether the direction of force transmission is smooth and stable when they push each other. Different angles are prone to jamming and noise.

Leave a small gap: When the teeth bite, a tiny gap needs to be left between the sides. This gap is to make them run smoothly without getting stuck, to add lubricating oil, and to offset the slight errors in thermal expansion and contraction or installation. But this gap cannot be too large, otherwise it will make a clanging sound, wear quickly, and the position will be inaccurate. It is important to adjust this gap during installation.

4. Assembly method

- Parallel alignment: The rotation axis of the pinion must be parallel to the direction of movement of the rack. If it is crooked, only part of the teeth will be strained, and they will be worn out quickly, and they will be noisy and vibrating.

- Tooth to tooth: The width direction of the pinion teeth should be aligned with the length direction of the rack teeth.

Is there a big difference between gear and pinion machining?

1. Small gears are relatively difficult to operate

The pinion is small in size, and it is more difficult to clamp it on the machine tool. It must be clamped firmly without loosening, but it must not be deformed by clamping it too hard. The operation requires more skills.

Because the parts are small, a little error has a great impact, so the measurement is naturally more delicate and time-consuming than that of large gears.

2. Higher precision requirements

The pinion machining often drives the large gear or rack, and is the starting point of power transmission. A slight shape deviation or inaccurate position on its teeth will be amplified by the large gear behind it, resulting in significantly increased noise and vibration, and unstable transmission. Therefore, the tooth shape accuracy and pitch accuracy of the small gear are usually more stringent than those of the passive large gear.

3. The structure is easy to deform

The small gear usually has a thinner wall or a more complex shape. During the tooth cutting process and subsequent heat treatment, it is more likely to be distorted and deformed than the thick large gear. Controlling this deformation is a key challenge in processing pinion.

How does pinion processing technology serve different industries?

1. Medical devices

Used in surgical robot joints, precision dental drills, insulin pumps, and endoscope probes.

Human life is at stake, requiring extremely high gear transmission accuracy, absolutely reliable operation, and extremely low noise. Processing technology ensures smooth and accurate movement, and the material must also have good biocompatibility and corrosion resistance.

2. Automotive industry

Hidden in automatic transmissions (especially planetary gear sets), turbocharger adjustment mechanisms, electric window/seat motors, various sensors and actuators.

Directly affecting driving experience and reliability, processing technology allows these pinions to withstand high torque and wear resistance, ensuring smooth shifting, smooth and quiet functional operation, and improving transmission efficiency and vehicle fatigue life.

3. Consumer electronics

Drives micro vibration motors in mobile phones, autofocus and optical image stabilization mechanisms in camera modules, smart watch knobs, drone gimbals, etc.

Pursuing extreme miniaturization and silence, processing technology achieves precise meshing in extremely small sizes, with sensitive and reliable movements and almost silent operation, which directly affects the feel and functional stability of the product.

4. Aerospace and military industry

Used in aircraft actuation systems, missile servos, precision optical instrument adjustment mechanisms, and inertial navigation equipment.

Extreme environments have strict requirements. Processing technology ensures that gears maintain dimensional stability and transmission accuracy under severe vibration and huge temperature differences. Material strength and lightweight are the key, which directly affects equipment performance and reliability.

5. Precision instruments and automation

Drive the sample stage of laboratory analytical instruments, the precision motion platform of semiconductor manufacturing equipment (such as lithography machines), and the inside of the harmonic reducer of industrial robot joints.

The core lies in the positioning accuracy and repeatability of micrometers or even nanometers. Processing technology is the basis for achieving ultra-precision transmission, eliminating return clearance, and ensuring long-term stable operation of equipment.

What are the key factors to consider in pinion machining?

1. Precision requirements

The pinion tooth shape and tooth direction must be very accurate, the tolerance of key dimensions must be strictly controlled (micrometer level), and the gear shaking when rotating must be very small.

2. Tooth surface quality

The tooth surface must be very smooth, hard and wear-resistant, which usually requires heat treatment of the pinion.

3. Material selection

The material depends on where the gear is used, such as high strength, wear resistance or corrosion resistance. Commonly used materials are alloy steel, stainless steel or engineering plastics, which must meet performance requirements and be easy to process. JS provides over 50 types of materials to meet your needs for pinion machining materials.

4. Structural design

The root of the gear must be designed to be strong enough, and the entire structure must be easy to process and manufacture.

5. Processing technology

Select the appropriate processing method according to the precision requirements and production quantity. Hobbing or gear shaping is commonly used for rough processing, and grinding or honing is used for fine processing.

- Use high-precision machine tools and tools.

- The pinion must be fixed very firmly during processing to prevent deformation.

- The heat generated during processing must be controlled to avoid affecting the accuracy.

6. Post-processing

- Burrs must be cleaned up: All burrs and flash left after processing must be completely removed.

- Cleanliness cannot be sloppy: Some industries, such as gears used in medical and semiconductor equipment, have extremely strict requirements on cleanliness.

Summary

Pinion machining combines material selection, precision machining, heat treatment and strict testing. At JS, we start with precise design and select suitable steel to process the gear blank. In the critical heat treatment process, JS relies on experience to accurately control and ensure that every size and tooth shape is perfectly up to standard.

It is these precise and interlocking steps that ensure that the pinions produced by JS can achieve accurate, reliable and quiet power transmission in harsh environments such as automotive gearboxes and precision equipment.

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is a pinion?

A pinion is a smaller gear in a mechanical transmission. It usually meshes with a larger gear to form a gear pair, which is used to transmit power and motion, and change the speed or torque. It is commonly found in various mechanical systems, clocks, automobile gearboxes and other equipment.

2. What should be paid attention to when designing a pinion?

Select high-strength materials (such as alloy steel), accurately calculate the tooth shape and size to ensure smooth meshing, perform surface hardening treatment to improve wear resistance, design effective lubrication to reduce friction and wear, and ensure installation accuracy and rigidity to prevent partial load failure.

3. What are the standards for a good gear?

Smooth and accurate transmission, strong load-bearing capacity, wear resistance and fatigue resistance, not easy to fail under expected working conditions, and manufacturing accuracy meets the standards.

4. How long is the life of a pinion processed by JS?

The life of a pinion processed by JS can usually reach more than 10 years, depending on the usage scenario and load intensity. We significantly improve wear resistance through selected materials, precise heat treatment and micron-level tooth surface polishing. Thirty years of precision manufacturing experience ensures that each gear is durable.

Resource