Although the pinion is small, it plays a key role in precision mechanical equipment, it must transmit power steadily and control movement accurately. How long this small part can be used and how well it performs actually depends largely on what material you choose to make it. Different materials, such as durable steel, rust-proof brass, or lightweight engineering plastics, each have their own advantages and disadvantages and applicable scenarios.

Next, let's take a look at the characteristics of the commonly used materials for pinion machining to help you choose the right material for your next project and easily solve the material selection problem.

What is pinion machining?

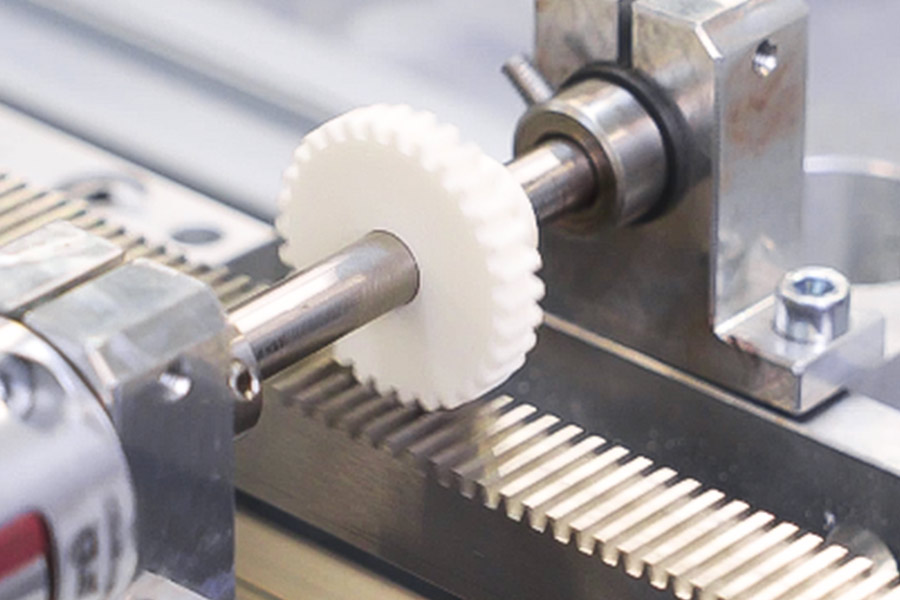

Usually, we regard gears with a modulus less than 1mm and a diameter less than 10mm as pinions. They are used in compact and extremely demanding micro-equipment, such as medical devices, robot joints, and micro reducers. This requires that the pinion machining precision must be extremely high, and the surface must be as smooth as a mirror to ensure smooth transmission, low noise, high efficiency, and long life.

Machining these pinions is very challenging: the small size makes clamping difficult, and the shape, direction and spacing of the tiny teeth must be extremely accurate. The tolerances of size, roundness, runout, etc. are very strictly controlled. At the same time, the tooth surface must be extremely smooth to reduce friction and wear.

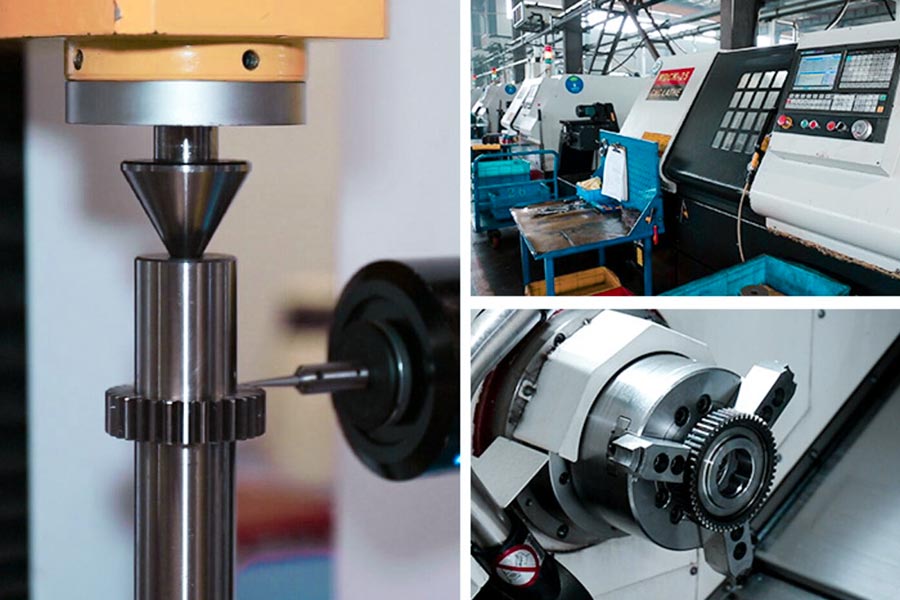

How does pinion machining work?

1. Precision material preparation

- Material selection: Commonly used are high-strength alloy steel, stainless steel or hard engineering plastics.

- Preliminary molding: After getting the material, the first step is to make a blank close to the shape of the gear. In order to save material and reduce the amount of subsequent processing, precision turning or cold heading (that is, to make the metal form a rough shape) is generally used to complete this step.

2. Core process: tooth shape machining

With the initial blank, the most critical tooth shape part begins to be processed. There are two main mainstream methods:

(1)Gear hobbing

- The principle is very simple: Use a high-speed rotating, toothed hob and a rotating workpiece to bite each other, just like printing out a mold, and roll out a precise involute tooth shape.

- High machine requirements: A computer-controlled CNC gear hobbing machine must be used, equipped with an ultra-small, ultra-precision hob (the modulus is as small as 0.1-0.3, and the blade must be diamond-plated, which is harder and more wear-resistant).

- Precision is the key: The machine itself must be particularly stable, the position error cannot exceed 0.003 mm each time it is repeated, and the spindle must swing less than one thousandth of a millimeter (1 micron) when it rotates.

(2)Gear hobbing

- Generally used to handle special structures. Some gear shapes cannot be hobbed, such as those with teeth inside or several gears stacked together (multi-link gears), so gear hobbing can only be used.

- It uses a very small (2mm) small gear hobbing cutter that jumps up and down at high speed to cut out the teeth one by one.

3. Fine pinion machining and molding technology

Sometimes, in order to achieve better performance or process particularly difficult-to-cut materials, more sophisticated molding methods are used:

Cold extrusion molding:

- In short, it is to use a very hard mold, under great pressure, to directly squeeze the metal blank into a gear shape like kneading plasticine. This is not cutting.

- The metal texture inside the gear surface of the extruded gear is continuous and complete, without any traces of cutting, and the overall strength can be increased by more than 30%. Therefore, we often use this method to process those small and demanding gears in watches.

Powder metallurgy:

- Use ultra-fine metal powder or ceramic powder, first inject it into the mold like an injection, and get a green billet with a shape that is very close to the final product, and then heat it at high temperature to sinter and shape it.

- Obvious advantages: Complex-shaped teeth can be made directly, such as helical gears and herringbone gears, and the finished product has basically no burrs, saving the subsequent process.

4. Final finishing process

After the rough processing or forming of the tooth shape, the surface accuracy may not meet the standard and further finishing is required:

- Precision shaving: Use a shaving cutter with a special blade to gently scrape the rolled/inserted gear tooth surface, removing only a little metal about 5 to 10 microns thick, making the tooth surface smoother and more regular.

- Honing: Let the gear and an abrasive-coated ceramic honing wheel bite each other, contacting while turning. Using the tiny friction between them and the effect of the abrasive, the tiny flaws are ground away little by little, and the tooth surface is further polished, and the surface roughness can reach a very low level (Ra value is better than 0.1 micron).

- Chemical mechanical polishing: If the tooth surface needs to be extremely smooth and achieve a mirror effect (such as used in precision medical equipment), use CMP. This method can obtain a tooth surface with ultra-high precision finish (Ra less than 0.05 microns).

5. Ensure quality

No matter how well the gears are made, they must be strictly inspected to ensure quality:

Core inspection equipment: JS usually uses a special computer-controlled coordinate measuring machine, which can accurately measure the key parameters of the gears, mainly including:

- Is the tooth profile accurate?

- Is the direction of the teeth skewed?

- Are all the teeth evenly distributed around the center?

Real-time adjustment: The most important thing is that the detected data can be directly told to the processing machine. The machine can immediately fine-tune the tool's motion trajectory based on these results, and compensate for the error just measured in the next workpiece or subsequent processing steps. Form an automatic cycle of measurement, correction, and reprocessing to ensure that the gears are perfect.

Technical difficulties and solutions:

| Challenge | Key technical countermeasures for JS |

| Cutting tools are prone to deformation/breakage | Diamond/cubic boron nitride (CBN) coated cutting tools. |

| Small workpiece clamping deformation | Vacuum suction cup/low stress elastic fixture. |

| Cutting heat causes dimensional drift | Micro lubrication (MQL) low-temperature cutting. |

| Burrs are difficult to remove | Electrolytic deburring/plasma etching. |

What materials are used for pinion machining?

Most commonly used metal materials

1. High-strength alloy steel:

- Carburizing steel: Such as Japan's SCM415, China's 20CrMnTi, and the United States' 8620.

- Quenching steel: High-carbon chromium bearing steel such as SUJ2 and GCr15.

Processing technology:

- Carburizing and quenching: Make the surface of the pinion very hard (up to HRC58-62), very wear-resistant, while the core maintains good toughness and is not easy to break. Small reduction gears in cars are often used in this way.

- Vacuum heat treatment: Especially suitable for processing very small and extremely high-precision pinions (module less than 0.3mm), which can effectively reduce gear deformation.

Advantages: Pinion made of this material are particularly durable, can withstand great force and are not easy to break, and have good impact resistance. They are most suitable for places where you need to exert force and work hard.

2. Stainless steel

- Austenitic stainless steel: Very corrosion-resistant, not easy to rust, we often use it on pinion in medical equipment or food machinery that need to be cleaned frequently or exposed to special environments.

- Martensitic stainless steel: It can be hardened by heat treatment (surface hardness can exceed HRC50) and is relatively wear-resistant.

- Special requirements: Pinion like those in surgical robots must also pass special biosafety certification (such as ISO 10993).

3. Special alloys

- Titanium alloy: Light, strong, and particularly corrosion-resistant. It is used in small and critical drive systems in aircraft and spacecraft.

- Copper alloy: It has a certain lubrication effect and good shock absorption ability. It is often used in transmission small gears in some precision instruments.

Engineering plastics

1. Common engineering plastics

| Material | Characteristic | Application scenarios |

| POM (polyoxymethylene) | High rigidity, low friction coefficient, easy to process. | Printer paper feeding gear. |

| PA66+fiberglass | Improved temperature resistance (120℃) and creep resistance. | Car window machine drive gear. |

| PEEK (polyetheretherketone) | 260℃ temperature resistance and chemical corrosion resistance. | High temperature transmission of semiconductor equipment. |

2.Special modified plastics

- Filled with graphite/PTFE: Improve self-lubrication (oil-free environment).

- Carbon fiber reinforcement: Improve rigidity and dimensional stability (robot joint gears).

What factors should be considered when choosing the right material for pinion machining?

1. Working conditions and load requirements

(1)Load type and size:

- The torque and bending stress of the pinion machining directly affect the force level of the tooth root and tooth surface. The greater the load, the higher the material strength required.

- If the system has frequent starts, stops, overloads or external shocks, the material needs to have good toughness to withstand these sudden forces.

(2)Speed:

The faster the gear rotates, the more heat is generated, and the greater the dynamic load and inertia force it is subjected to. This places higher demands on the material's high temperature strength, ability to resist fatigue damage, and wear resistance. At high speeds, the weight of the material may also affect the moment of inertia, which needs to be considered.

(3)Working environment:

- Temperature: High temperature will make the material softer, reduce strength and hardness, and may even cause slow deformation. Low temperature will make the material brittle and reduce toughness. When selecting materials, ensure that the materials can maintain the required performance at the working temperature.

- Corrosion: If the pinion machining is exposed to moisture, acid, alkali, salt spray or other corrosive environments, corrosion will greatly reduce the fatigue strength of the material. In this case, it is necessary to select corrosion-resistant materials or protect the pinion surface (such as coating, electroplating).

2. Functional requirements of pinion

- Strength and stiffness are the basis: The tooth root is anti-bending and anti-tooth breakage, and the tooth surface contact is anti-pitting and spalling. The key is the yield strength, tensile strength, bending and contact fatigue strength of the material.

- The tooth surface must be hard and wear-resistant: The contact surface hardness must be high to resist abrasive scratches and adhesive wear, and the wear resistance depends directly on the surface hardness.

- Toughness: The material must be tough and prevent brittle fracture. High strength and high toughness are difficult to take into account. Carburized steel is often selected for impact, and high-hardness quenched steel is selected for stable load.

- Fatigue resistance function: Pinion are repeatedly stressed, and fatigue damage (tooth breakage, pitting) is the main cause. Bending and contact fatigue limits are crucial.

- Dimensional stability: The precision requirements for pinion machining are high. Material selection should consider hardenability, small heat treatment deformation, and convenience for subsequent grinding correction.

- Lightweight: When aviation, automobiles, etc. need to reduce weight, lightweight materials (aluminum alloy, engineering plastics, powder metallurgy) or lightweight design can be selected while ensuring strength and stiffness.

3. Heat treatability of materials

- Hardenability: The ability of a material to obtain the required hardness, especially when the size is large. Pinions are small in size, and hardenability is usually not a big problem, but uniformity needs to be considered.

- Heat treatment deformation:The size and shape changes caused by different materials and heat treatment processes vary greatly. Heat treatment deformation is one of the main factors affecting the precision of pinions. It is necessary to select materials with good heat treatment processability and small deformation, or reserve sufficient margin for subsequent finishing. Carburizing quenching and induction quenching are often used for hard tooth surfaces.

4. The particularity of pinions

- Failure risk: In the gear train, pinion machining has a small number of teeth and each tooth participates in meshing more times. In theory, it is more prone to fatigue failure than large gears. The selection of materials should focus more on their fatigue strength and surface durability.

- Design size: Small size is relatively easier to harden, and the heat treatment process may have more room for selection.

Which is more durable, steel or plastic gears?

1. Steel pinions are usually more durable and have a longer lifespan:

- Material is strong and hard: Steel itself is very strong and hard, and can withstand a lot of force and is particularly resistant to wear. This means that under the same hard work, steel teeth are not easily worn flat or squeezed out of shape.

- Heat and pressure resistance: It can withstand higher working temperatures, greater pressure and torsional force, and it is not easy to get tired and deformed or cracked after a long time of hard work.

- Life advantage: In general, in places where heavy work, high force, high speed or high ambient temperature are required, steel pinion machining will give you a longer use time.

2. Plastic pinions are generally not as wear-resistant as steel:

- Afraid of heat and deformation: Plastics tend to soften and deform when exposed to high temperatures, and their strength is also poor. Under continuous strong force or high-speed rotation, it is more likely to wear, crack or deform directly.

- Afraid of aging: Some plastics will become brittle over time, or their performance will deteriorate after contact with certain oils and chemicals.

- Lightweight and quiet: The advantages of plastic are light weight, quiet operation, and in many cases no additional oiling and maintenance are required, and it will not rust.

Our selection recommendations:

- If you need to withstand wear and tear and use it for a long time, steel gears are the first choice. For example, the key gears in the car gearbox and the parts responsible for high-power transmission in factory machines.

- If you care more about light weight, low noise, and few environmental restrictions, plastic gears may be able to be used and more cost-effective. For example, the pinion machining in toys and the light-loaded gears in home appliance timers.

Will choosing cheap materials shorten the life of the pinion?

Generally speaking, choosing cheap materials is likely to shorten the life of the small gears, but this depends on how to change the materials and where the gears are used.

1. Change to worse materials (such as plastic to steel):

This will almost certainly shorten the life of the pinion machining. Plastics are far inferior to steel in strength, heat resistance, and wear resistance. If plastic is used where steel should be used to save money, the gears are easily deformed, worn or cracked under high force, high speed or high temperature, and the life is greatly shortened.

2. Use cheaper similar materials:

This is risky. It is not 100% certain that something will go wrong, but the probability of something going wrong is higher.

For example, cheap steel may have more impurities, poor heat treatment, or lower strength level. This kind of pinion machining is more likely to deform, wear faster, or easily produce metal fatigue under heavy loads. It may not break immediately, but it is definitely not as durable as good steel, and the lifespan may be reduced unknowingly.

Or use cheaper plastic, which may be softer, more afraid of heat, and more prone to aging and brittleness. Under the same use environment, it will break faster.

Key points to note:

- If the pinion machining is just a gentle rotation in a household blender, it may be fine to use cheaper materials. But if it is rotating at high speed in a factory machine, saving money on materials is very risky, and there is a high probability of early scrapping.

- What does cheap mean? For example, plastic is used when steel should be used? Or is the same material of poor quality? Obviously, the first one has a greater impact, but the second one may also have great risks.

Our money-saving tips:

- Think carefully about how much force the gear needs: If the force is really small, the speed is slow, and the environment is not harsh, you may be able to choose the right plastic.

- Find a reliable supplier: The same nylon or steel, different manufacturers make very different quality. Find a reputable supplier, using regular and cheaper materials is usually safer than finding a brand-name manufacturer.

Summary

Pinion machining, it is not easy to choose materials for it. At JS, we know that this requires a comprehensive assessment of the material's strength, toughness, wear resistance, and processing and manufacturing feasibility. Our professional team will deeply understand the characteristics of different materials, closely combine the working scenarios and performance requirements of pinion machining, and make accurate choices.

Please remember that for precision transmission systems, the high-performance materials that JS matches for pinions directly determine whether the entire system can operate long-term and reliably, which is the core value of our technology accumulation.

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is the primary consideration when selecting materials?

The primary consideration for selecting pinion materials is to meet the performance requirements of the working conditions, match the feasibility of the processing technology, and finally optimize the cost-effectiveness. For example, alloy steel is used in heavy-duty scenarios, stainless steel is selected in corrosive environments, and economical carbon steel is used in ordinary working conditions.

2. When to use stainless steel?

Stainless steel is suitable for scenarios with high corrosion or strict cleanliness requirements. For example, when the gears of food processing equipment are exposed to acid and alkali detergents, ship gears are exposed to salt spray environments, or medical equipment needs to be frequently disinfected. At this time, some cutting economy is sacrificed in exchange for corrosion resistance, but the cost is 40%-60% higher than carbon steel.

3. What are the advantages of alloy steel?

Alloy steel improves core performance by adding elements such as chromium and nickel: significantly improves strength and hardness while maintaining good toughness. Enhances wear resistance and fatigue resistance and extends gear life. Allows fine adjustment of performance through heat treatment. Suitable for harsh working conditions such as heavy loads and high speeds, although the cost is higher than carbon steel, it has excellent cost performance.

4. Are finishing requirements related to materials?

Finishing requirements are directly related to material properties. Material hardness affects tool selection and surface finish. Ductility is related to burr control. Heat treatment stability determines dimensional accuracy. Different materials require targeted adjustment of cutting parameters.

Resource