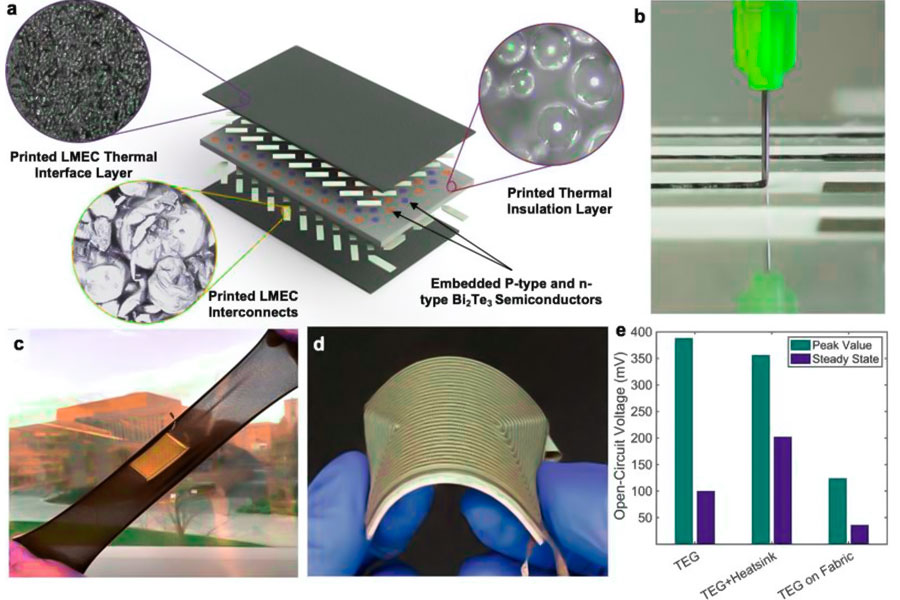

잉크 제트 인쇄 기술 , 3D 프린팅 기술은 전통적인 프로세스 제한을 극복하고 복잡한 구조 및 빠른 프로토 타이핑 개발을 달성하여 개인화되고 확장 가능한 생산을위한 혁신적인 솔루션을 제공합니다. 고화 된 잉크젯 인쇄 기술을 3D 인쇄에 결합하여, JS 제조업을 제공합니다. 기능성 복합 그라디언트 제조의 새로운 패러다임을 개척하십시오.

3D 인쇄의 기본 정의는 무엇입니까?

3d Printing (additative a digital manufaction). 정밀 광고 공합 또는 핫 멜트 라미네이션을 통한 물리적 구성 요소. 생체 모방 형태와 기능의 유기적 조합을 처리하고 실현했습니다.

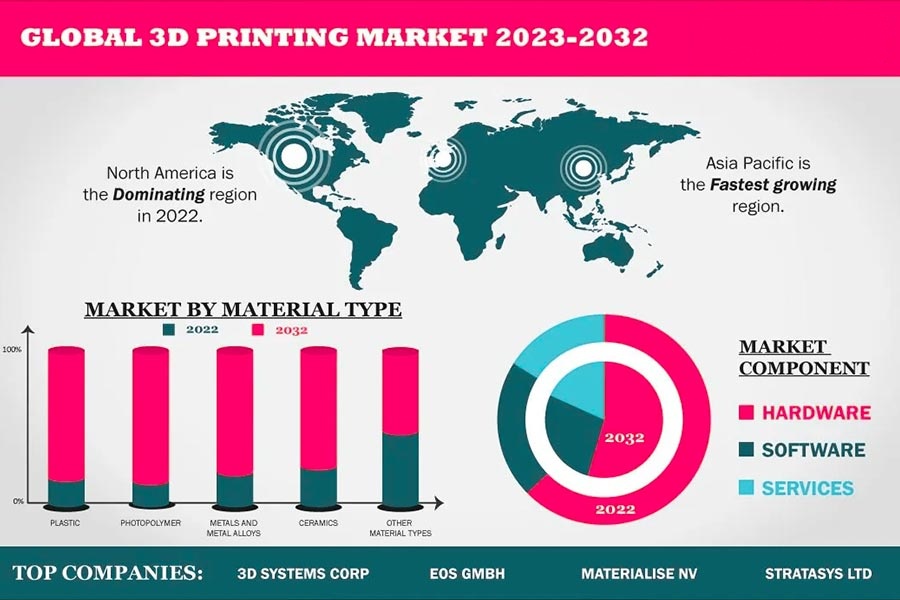

기술적으로 3DPrinting은 FDM, SLA 또는 SLS와 같은 프로세스에 의존하여 다중 재료 복합 구조를 가능하게합니다. 서비스 차원에서 3D 프린팅 서비스는 매개 변수 모델링에서 최종 제품 전달에 이르기까지 실현합니다. 글로벌 3D 프린팅 시장은 어떻게 발전하고 있습니까?

여기서 시장 크기의 분석이 있습니다. 1. 글로벌 규모 및 성장 추세 3D 프린팅 모델 는 산업 프로토 타입, 의료 임플란트 및 소비자 제품 개발을 포함하여 설계 및 제조 요구 사항의 35% 이상을 차지합니다. 인쇄 서비스, 비즈니스의 핵심 사업 전략, 핵심 운영 비용, href = "https://jsrpm.com/contact-us"> 구동 생산 및 소규모 커스터마이징 . 2. Global 3D 인쇄 시장 크기 데이터 (2022-2027) 세분화 된 시장 및 지역 분배 <기술 유형에 의한 데이터 -v-7b79c893 = ""> Metal 3D Printing (35%) : 폴리머 3D 인쇄 (40%) : 시장 : 미래 성장 드라이버 재료 제한 3D 인쇄 모델에 사용할 수있는 재료 범위가 제한된 경우, 특히 고성능 필드에서 제한됩니다. href = "https://jsrpm.com/blog/what-materials-are-used-in-printing"> 3D 산업 등급 금속의 인쇄 는 매우 높은 분말 순도가 필요하지만, 기존의 수지 재료는 장기적인 내구성 요구 사항을 충족하는 데 어려움을 겪고 있으며, 이는 항공 우주, 기타 의료 임시 모델에서 3D 프린팅 모델의 적용을 직접 제한하는 데 어려움을 겪습니다. 시나리오.

년

시장 규모 (수십억 달러)

연간 성장률 (CAGR)

핵심 성장 영역

주요 주행 요소

2022

240

15.3%

항공 우주, 의료, 자동차.

금속 3D 인쇄 모델에 대한 수요가 폭발했습니다.

2023

276

15.3%

금속 인쇄, 치과 모델.

인쇄 서비스 홍보.

2025

375

16%

지능형 제조, 건물 모델.

다중 물질 3D 프린팅 모델의 획기적인 혁신.

2027

500

15.3%

바이오 프린팅 및 개인화 된 소비자 제품.

클라우드 인쇄 서비스 확장.

지역

2022 년 시장 규모 (수십억 달러)

주요 성장 드라이버

북미

90

항공 우주 및 자동차 제조.

유럽

75

의료 임플란트, 건물 모델.

아시아 태평양

60

전자 제품, 치과 커스터마이징.

다른 지역

15

교육 및 문화 및 창의적 제품.

3D 인쇄의 과제와 한계는 무엇입니까?

2. data-translateid = "06d5b62876aee919c3899c1642d057fd"data-pos = "3"data-len = "35"data-v-7b79c893 = "" "> <">

기술의 발전에도 불구하고 3D 인쇄 모델의 정확도는 장치 해상도 및 계층 두께에 의해 여전히 영향을받습니다. href = "https://jsrpm.com/3d-printing"> 미니어처 기어와 같은 미량의 스케일 정밀도 가 필요합니다.

복잡한 구조의 설계 제한

while 3d 인쇄 형태를 생성하는 복잡한 구조물 변형 또는 표면 결함.

< ">

5. data-len = "41"data-v-7b79c893 = "" "> 표준화 및 인증 부족

산업 부문은 엄격한 재료 성능과 안전 표준을 가지고 있지만 3D 프린팅 모델에 대한 프로세스 매개 변수에 대한 균일 한 인증 시스템이 없기 때문에 상용화가 어렵습니다.

. 6. data-translateid = "7fd03fc5c9e0c2d771d520e3b41668ea"data-pos = "3"data-len = "34"data-v-7b79c893 = "" ">

대부분의 3D 인쇄 모델은 최종 성능 요구 사항을 충족 시키려면 연삭, 연마 또는 열 처리가 필요합니다. < "> 기계적 특성의 층 및 교정은 수지 모델이 청소 및 보조 경화가 필요하므로 리드 타임이 크게 길어집니다.

환경 및 지속 가능성 문제

3d 인쇄물은 자원 폐기물을 줄이기 위해 제조 및 기술 혁신이 필요합니다.

3D 프린팅은 프로토 타이핑에 어떻게 사용됩니까?

1. data-len = "37"data-v-7b79c893 = "" "> 빠른 반복 및 설계 검증

- 3D 프린팅은 CAD 디자인을 물리적 프로토 타입으로 빠르게 변환하여 개념에서 물리적 개체로주기를 단축 할 수 있습니다.

- JS 기술 협회 : Step 및 STL과 같은 3D 파일 형식 업로드 및 약속 24 시간 내에 약속합니다. 프로토 타입 생산에서 후속 개발 단계로 원활한 전환을 보장합니다.

<

- SLA 및 SLS와 같은 3D 프린팅 기술은 ± 0.005mm 정확도를 달성하며 복잡한 구조 또는 정밀 구성 요소의 프로토 타입 검증에 적합합니다.

- JS 기술 협회 : JS의 CNC 가공 정확도는 3D 인쇄를 통합하여 ± 0.005mm 를 통합 할 수 있습니다. 정확도.

- 3D 프린팅은 금속 (티타늄 합금, 스테인리스 스틸), 플라스틱 (나일론, ABS), 복합재 등과 같은 재료의 프로토 타이핑을 지원합니다.

- JS 기술 연관성 : 50 가지 이상의 재료의 라이브러리와 함께 금속, 플라스틱 및 복합재에 대한 처리 서비스를 제공합니다. 3D- 프린트 프로토 타입 최종 생산 솔루션을 최적화하십시오.

<"> < ">

5.Formation of complex complex structures 6.Green manufacturing practices 1.Medical and Biotechnology Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc. JS technology association: 2.Automotive and Aerospace Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades). JS technology association: 3.Education and research Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development. JS technology association: 4.Industrial manufacturing Application scenarios: Mold inserts, fixtures, automation equipment components. JS technology association: Real-time application analysis of JS Consumer electronics industry: Cooling components for smart wearables Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces. Technical difficulties: JS company solution: 1.Process selection 2.Design optimization 3.Quality control 4.Technical highlights 5.Achievements 1.Material innovation New high-performance metal alloys: Breakthroughs in biocompatible materials: Expansion of Composites Applications: 2.Technological breakthroughs 3.Extension of application In the medical field: Aerospace: 4.Sustainable technology 5.Frontier exploration 1.Automated process upgrades 2.Intelligent scheduling and resource management 3.Innovations in materials and processes 4.Standardization and lean production 5.Energy and equipment maintenance management The application of 3D printing technology has pushed the boundaries of traditional manufacturing, from lightweight smart wearable devices in the consumer electronics industry to precision parts maintenance and complex structural innovations in industrial equipment. Not only does the technology shorten product development and reduce customization costs, it also provides unprecedented solutions for the industry through the diversity of materials and process flexibility. A pioneer in 3D printing technology, JS is driving the transition 3D models printing from prototype validation to mass manufacturing with its high precision processing capability (e.g. ±0.005mm tolerance), multi-material compatibility and intelligent manufacturing processes. Whether personalized prosthetics in the medical field or abrasion-resistant coating repairs for industrial devices, 3D models printing is redefining manufacturing possibilities. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.How to use 3D printing to customize prosthetics in the medical field? Through medical scanning modeling, biomaterial 3D printing and other methods, personalized prosthetics are designed to meet patients' needs accurately. 2.Can 3D printing produce complex mechanical parts? By using SLM and other technologies, complex metal parts such as aircraft engine blades and automobile transmission components can be manufactured directly, breaking through the limitation of traditional technology. 3.What parts can be 3D printing for cars? Cars can be 3D printed with lightweight components such as brackets and gears, interior parts, prototypes and tool fixtures to improve design freedom and productivity. 4.How can 3D printing help with school teaching? 3D printing supports students to build hands-on models, visualize abstract concepts, improve practical skills, and think creatively.

JS 빠른 프로토 타이핑 및 빠른 제조 전문가 CNC 가공, 3D 프린팅, 우레탄 주조, 빠른 툴링, 사출 성형, 금속 주물, 판금 및 압출을 전문으로합니다. 꼬리표:

What industries are currently covered by 3D printing technology?

What are the latest developments in 3D printing technology?

How can JS achieve a 15% efficiency improvement in 3D printing?

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment preparation time (single order)

8 minutes

20 minutes

+60%

Post processing time (per piece)

12 minutes

30 minutes

+58%

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment utilization rate

82%

65%

+26%

Order delivery cycle

4.5 days

5.5 days

+18%

<테이블 스타일 = "Border-Collapse : 붕괴; 너비 : 100%; 경계 넓음 : 1px; 경계 색상 : #000000;" Border = "1">

Indicator

JS scheme

Other printing shops

Efficiency improvement

Material switching time (single order)

3 minutes

15 minutes

+80%

Single layer printing time (SLA)

3 seconds

6 seconds

+100%

<테이블 스타일 = "Border-Collapse : 붕괴; 너비 : 100%; 경계 넓음 : 1px; 경계 색상 : #000000;" Border = "1">

Indicator

JS scheme

Other printing shops

Efficiency improvement

Clamping time (single order)

5 minutes

15 minutes

+67%

Novice training cycle

1 day

3 days

+67%

<테이블 스타일 = "Border-Collapse : 붕괴; 너비 : 100%; 경계 넓음 : 1px; 경계 색상 : #000000;" Border = "1">

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment downtime

2 hours/week

5 hours/week

+60%

Unit energy consumption cost

$0.8/hour

$1.2/hour

+33%

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources

관련 블로그

Criticism

Featured Blogs