3D印刷技術は、デジタル製造で生産の論理を再構築しています。 "data-len =" data-len = "data-len =" data-len = ""> ">製造の。 デザインと生産の間のリンク、3Dプリントモデルの間のリンクは、有効なツールを有効にします。 jsは、プロの3D印刷サービスを提供する< href = "https://jsrpm.com/blog/how-does-3d-printing-work"> fdm、sla、sls、および金属印刷プロセスは、プロトタイプ開発から小型バッチ生産まですべてをサポートし、イノベーションを支援し、革新を支援し、革新を支援します。

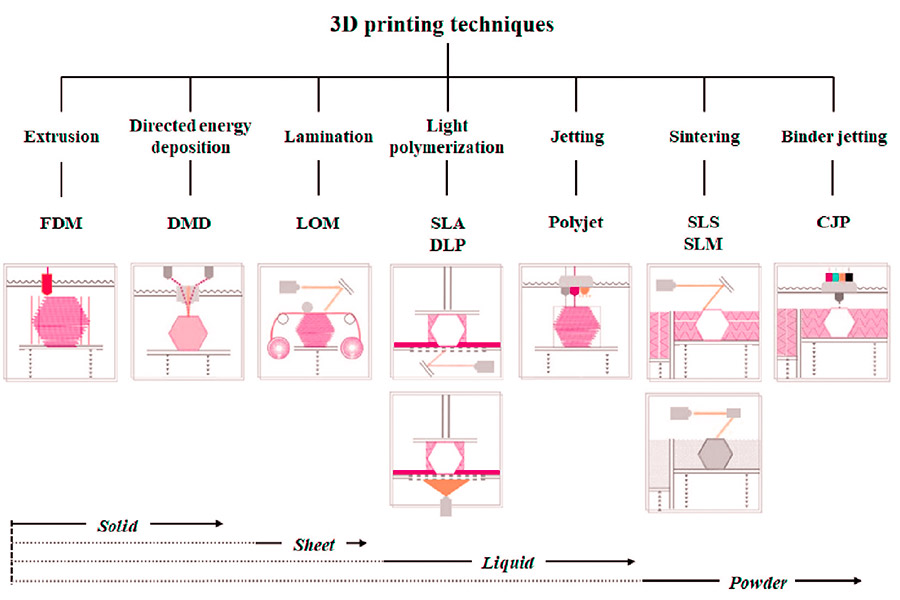

1. fused 堆積モデリング(fdm) 2.StereoLithography(SLA) 3。 data-len = "32" data-v-7b79c893 = ""> 選択的レーザー焼結(SLS)

5。 data-pos = "2" data-len = "30" data-v-7b79c893 = "" "> 選択的レーザー融解(SLM) 比較テクノロジー 1.層の厚いほど、層間の接着が弱くなります 2。 data-len = "57" data-v-7b79c893 = ""> レイヤーが厚いほど、密度の高い構造

層の厚さと材料特性のバランス 1.ティックレイヤーは素材を保存しますが、強度を犠牲にします 2。 data-len = "55" data-v-7b79c893 = ""> 薄い層は強度を追加しますが、印刷に時間がかかります 実際のアプリケーションでのレイヤーの厚さの選択 1.機能パーツ対表示部品 2.材料プロパティの適応 1。 data-translateId = "fbd5b82e2df1324255a84edf9d0b4cc3" data-pos = "3" data-len = "31" data-v-7b79c893 = "">

Data-TranslateID = "6E82DB129939D697EF96C0383F6A7C4A" data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" " data-translateId = "9c8d0c9d004d7eaa4d3d8db94a4466e7" data-pos = "3" data-len = "32" data-v-7b79c893 = ""> スキャン速度が遅いほど、単位面積あたりの露出エネルギーが高くなるほど、治癒が深くなります。スキャンが速すぎる場合、治療法が不完全になる可能性があります。 data-translateId = "ffe4b3c216a21b0c77872d309cf51e13" data-pos = "0" data-len = "3" data-v-7b79c893 = ""> 層の厚さ(Z-Axis解像度) resin properties

Model Geometry

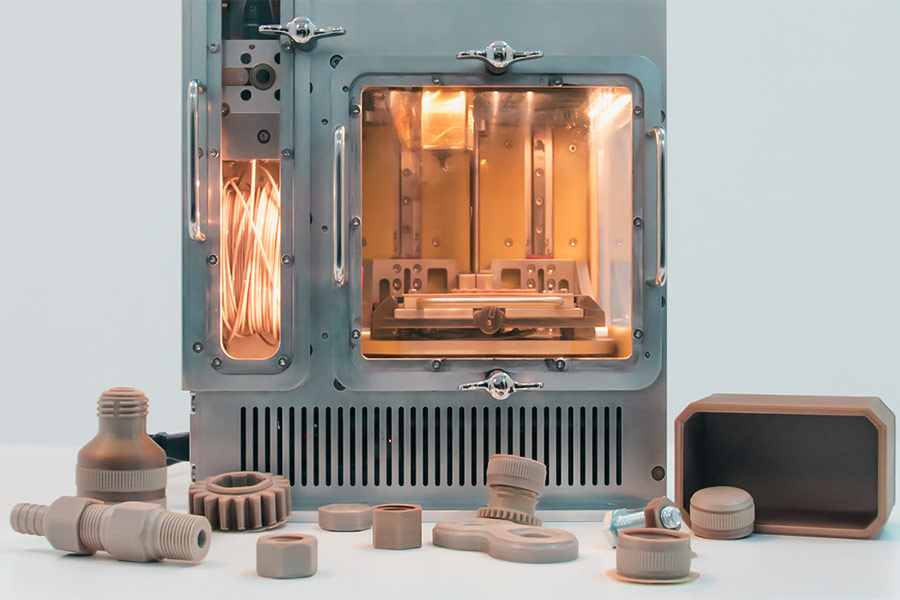

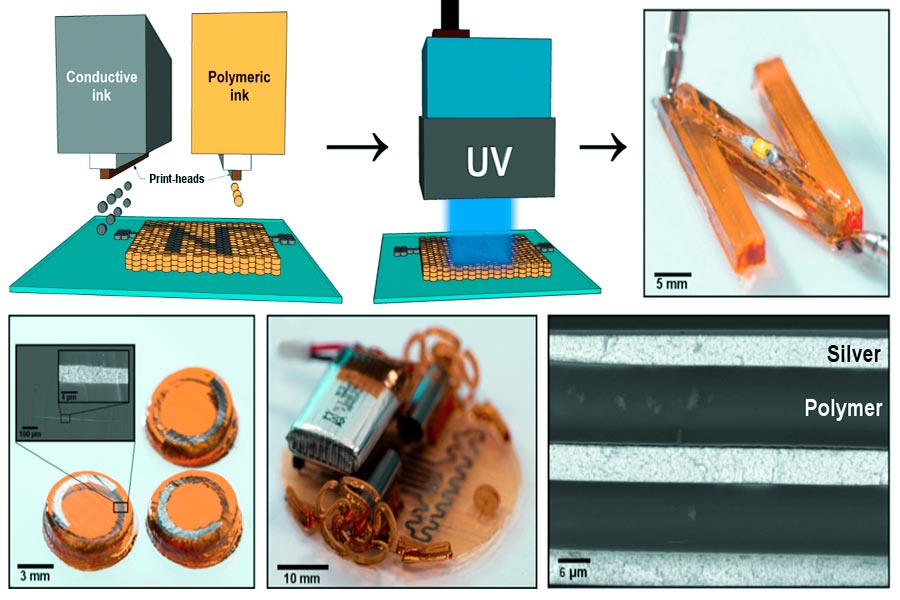

パラメーターの比較と最適化の提案表 By properly selecting parameter combinations, the 3D printing model can achieve precise manufacturing from concept verification to functional prototypes. 1.3D printing of metallic materials (high temperature environment preferred) SLM/DMLS (selective laser melting/sintering) 2.Ceramic 3D printing technology (ultra-high temperature resistance potential) SLA/DLP (light-curing ceramics) 3.High-Performance engineering plastic 3D Printing FDM (Molten deposition modeling) SLS (selective laser sintering) Technology selection recommendations for high temperature scenarios Ink jet printing technology is by layering liquid material on top of each other to create three-dimensional objects. Its core lies in high high-precision jetting and curing control. Specific implementation steps and key technologies are as follows: 1.Preparation of materials: Adaptation of liquid media 2.Ink jet print head: Precision droplet injection Piezoelectric drive or thermal foaming technology: 3.Layer by layer stacking: droplet solidification molding 4.Post-treatment: enhancement and surface optimization 1.Structural adaptation principle Overhang structure (>45°): Bridge structure (long span): 2.Matching and separation of materials Easy peel combination: Chemical dissolution combination: ABS+HIPS: Lemonin is needed to dissolve the scaffold and is suitable for complex internal parts such as gear components. 3.Actual performance requirements 4.Post-treatment efficiency Quick removal: Environmental Protection Plan: It is advisable to select biodegradable scaffolds (e.g. PBDE-based biodegradable materials) to reduce waste liquid treatment costs. 5.Printer adaptation FDM equipment: SLA/DLP equipment: 1.Multi-material printing technology support JS's 3D printing services include MJF and composite metal/ceramic printing technologies, which can switch different materials (e.g. metal-ceramic, carbide-polymer) during the same printing process to achieve continuous or segmented gradient changes in material composition. 2.Material compatibility and gradient design Through JS's 3D printing services, customers can choose from a variety of material combinations, including metals, ceramics and composites, and freely design the microstructure of functional gradient components (such as abrasionresistant + substrate layer). 3.Process optimization and performance assurance JS's industrial-grade equipment supports thickness control (±0.005mm) and temperature management to ensure uniform interface bonding strength and gradient transition across different materials and meet extreme working conditions such as high temperature and pressure. 4.Customized solutions For areas such as aerospace and medical devices, JS's team can provide a full range of services, from material selection and gradient structure design to reprocessing, such as: As a disruptive technology, 3dprinting continues to drive change in manufacturing with its diverse process types (e.g. FDM, SLA, metal printing, etc.) and a wide range of application scenarios (from industrial manufacturing to medical innovation). Whether it is the efficient production of complex functionally gradient parts or the rapid iteration of custom models, 3D printing services demonstrate irreplaceable flexibility and economy. Technology service providers represented by JS have further lowered the technology threshold by integrating multi-material printing, precision process control and industry-wide chain support, allowing businesses to focus on design innovation and value creation. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.Does SLS printing require support? SLS printing usually does not require support. The unsintered nylon powder will naturally envelop the model to avoid collapsing in the air. Only a few complex designs require a small amount of ancillary support, which greatly simplifies the reprocessing process. 2.Which technology is suitable for printing transparent parts? SLA technology is suitable for printing transparent parts. It uses photosensitive resin that hardens under UV light. The surface is smooth and transparent. Suitable for making high precision transparent model (such as optical parts). 3.What does the layer thickness of FDM affect? The thickness of FDM layer influences surface smoothness, printing time and printing strength. The thicker the layer, the more visible the pattern, the faster the printing, but the intensity may be reduced. 4.How big a part can 3D printing make? Industrial-grade 3D-printing devices can manufacture large parts of meters (such as aerospace parts), while desktop devices are usually limited to a few dozen centimeters and are suitable for small models or prototypes. 3D印刷技術の種類は何ですか?

3D印刷技術の種類は何ですか?

手法タイプ

速度

コスト

マテリアルタイプ

複雑さの処理機能

JS Companyに関連する利点

fdm

medium

low

plaやabs。 などのプラスチック

★★★

効率的な生産プロセス最適化速度。

sla

fast(dlp)

center

感光性樹脂。

★★★★

JS±0.005mm標準の高精度マッチングマッチング

sls

medium

center

nylon、tpuおよびその他の粉末。

★★★★

金属/複合アプリケーションの拡張をサポートしています。

mjf

非常に高速

中程度

nylon(pa12/pa11)。

★★★★

速い配信のためのバッチ生産効率の改善

slm

slow

tall

金属粉末(チタン、ステンレス鋼)。

★★★★

精密機械加工技術により、部品の複雑さが高くなります。

FDM印刷層の厚さの強度に対する効果は何ですか?

SLA印刷解像度を決定するパラメーターは何ですか?

パラメーター

解像度への影響

最適化方向

典型的な値

光源タイプ

laser> dlp(レーザーは同じ解像度でより高い精度があります)

精密モデル用のレーザーを選択し、大量生産用のDLPを選択します。

レーザー:50μm / dlp:100μm< / td>

スポットサイズ

スポットが小さいほど、詳細が明確です。

高精度レーザーヘッドまたは4K DLP投影を使用します。

50μm(レーザー)

スキャン速度

速度が遅いほど、硬化が完全になります。

細かい領域(0.1mm/sなど)で速度を下げ、広い領域でスピードアップします。

50-200mm/s

レイヤーの厚さ

層の厚さが半分になり、z軸の解像度が4倍増加します。

Use thin layers (25μm) for precision parts and thick layers (100μm) for speed increase.

50μm (standard)

Resin viscosity

Low viscosity improves fluidity and detail filling ability.

Use special resins (e.g. transparent resins with viscosity ≤1500cP).

500-2000cP

Model overhang angle

If the angle is too small, dense support is required, and blocking the light affects the curing.

Avoid <45° overhangs or add auxiliary supports in the design.

≥60° (unsupported)

Which printing technology is more stable in high temperature environments?

Scene temperature

Recommended Technology

Core advantages

Key capabilities of printing shops

600-1000℃

Metal SLM/DMLS.

High strength and creep resistance.

Laser equipment, vacuum environment, heat treatment.

1000-1500℃

Ceramic SLA/DLP.

Ultra high temperature resistance and corrosion resistance.

Specialized ceramic materials and high-temperature sintering process.

200-600℃

PEEK FDM, Nylon SLS.

Economy and lightweight.

Industrial grade equipment and material modification.

How to achieve layered stacking in 3D ink jet printing?

How to choose supporting materials for complex 3D printing models?

Can JS achieve functionally graded components through multi material 3D printing?

Summary

免責事項

jsチーム

For more information, please visit the official website: jsrpm.com FAQs

Resources

JS

迅速なプロトタイピングと迅速な製造専門家

CNC加工、3D印刷、ウレタン鋳造、迅速なツール、射出成形、金属鋳造、板金、押し出しを専門としています。

タグ:

共有します

Criticism

0 comments

Click to expand more

Featured Blogs

No data