インクジェット印刷技術、3D印刷技術は従来のプロセスの制限を克服し、複雑な構造と迅速なプロトタイピング開発を達成し、パーソナライズされたスケーラブルな生産のための革新的なソリューションを提供します。 buting fort for bous bour custom custom fort cortion fort forming forming forming forming forming forming機能的な複合勾配製造の新しいパラダイムの先駆者

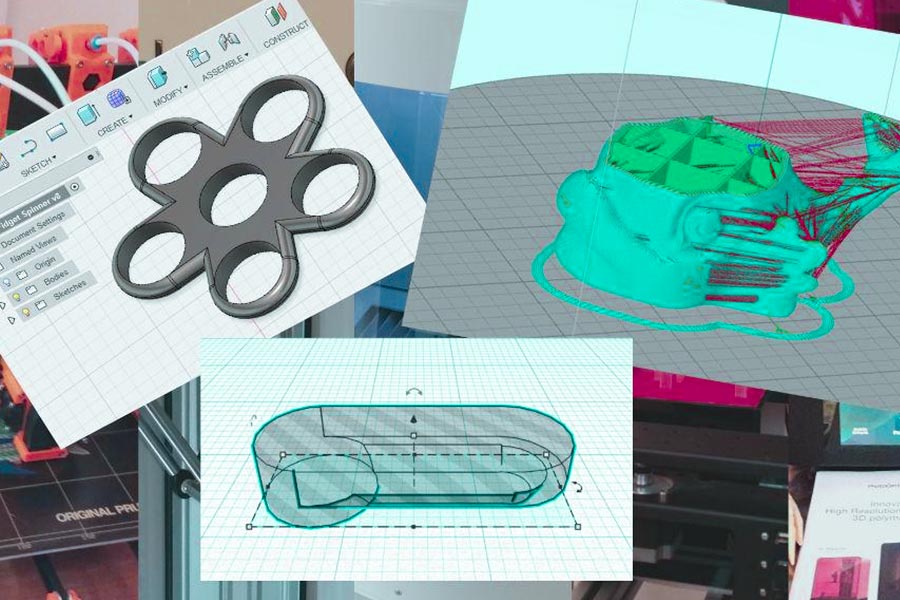

intecular aidular age <精密光重合または高温溶融積層による物理成分。 技術的には、3DprintingはFDM、SLA、SLSなどのプロセスに依存しているため、マルチマテリアルコンポジット構造が可能になります。 サービス寸法では、3D印刷サービスからデジタルサービスからのフルチェーンの配達を実現します。 この二重の革新がデジタルの革新を行うと、この二重の革新が施されています。カスタマイズ。 ここにあるのは、市場サイズの分析です。

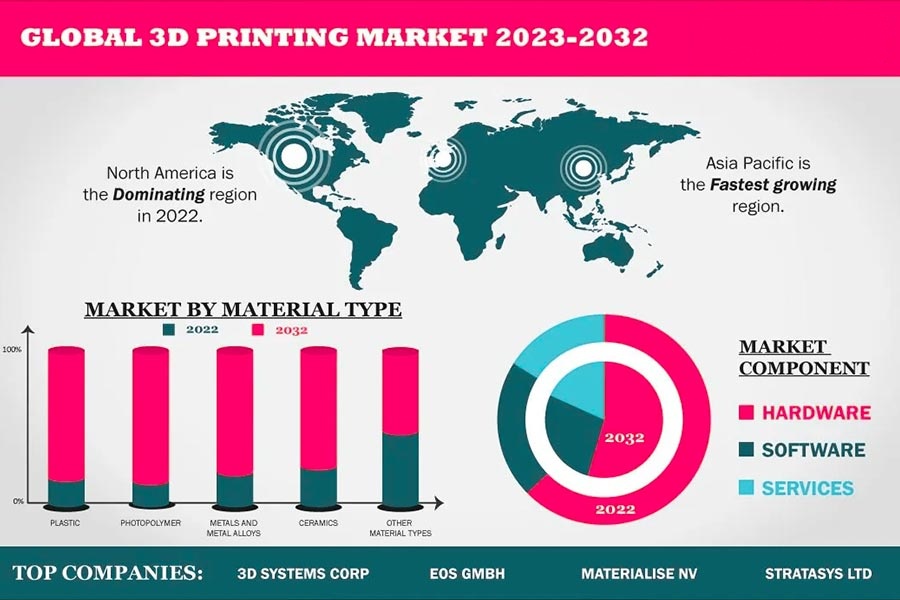

1. グローバルスケールと成長傾向 2023 woh readrers" 2022年までに240億米ドルに達すると予想されます。 href = "https://jsrpm.com/3d-printing"> 3D印刷モデル産業プロトタイプ、医療インプラント、消費者製品の開発など、設計および製造要件の35%以上を占めています。 < href = "https://jsrpm.com/contact-us">駆動型制作と小規模なカスタマイズ。 2.global 3D印刷市場サイズデータ(2022-2027) 3。 data-len = "43" data-v-7b79c893 = ""> セグメント化された市場と地域配信 metal 3d printing(35%): ポリマー3D印刷(40%): by市場: 4。 data-len = "21" data-v-7b79c893 = ""> 将来の成長ドライバー data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" ""> 1。 data-len = "20" data-v-7b79c893 = ""> 材料制限 3D印刷モデルで利用可能な材料の範囲が限られている場合、特に高性能フィールドで。 産業用グレードの金属の3D印刷には非常に高い粉末純度が必要です。

テクノロジーの進歩にもかかわらず、3D印刷モデルの精度は依然としてデバイスの解像度と層の厚さに影響されます。 "">可視階層パターンを生成できますが、光重合(SLA)は高精度ですが、不適切な再処理は表面の粗さにつながる可能性があります。 ミニチュアギアなどのミクロンスケール精度が必要です。 3。 data-len = "40" data-v-7b79c893 = ""> 複雑な構造の設計制限 3D印刷モデルは、ゆっくりとしている 産業部門には厳格な材料性能と安全基準がありますが、3D印刷モデルのプロセスパラメーターの均一な認証システムの欠如は、商業化が困難になります。

ほとんどの3D印刷モデルでは、最終的なパフォーマンス要件を満たすために研削、研磨、または熱処理が必要です。 機械的特性の層とキャリブレーション、樹脂モデルでは洗浄と二次硬化が必要であり、リードタイムを大幅に長くします。 1。 data-len = "37" data-v-7b79c893 = ""> 迅速なイテレーションと設計検証 data-translateid = "c0191cbeb2d83ced6c9a02e3b871d50d" data-pos = "3" data-len = "38" data-v-7b79c893 = "">

3.material data-translateId = "CDF53D93315C92C16B385EA81BDAF461" data-pos = "3" data-len = "29" data-v-7b79c893 = "">

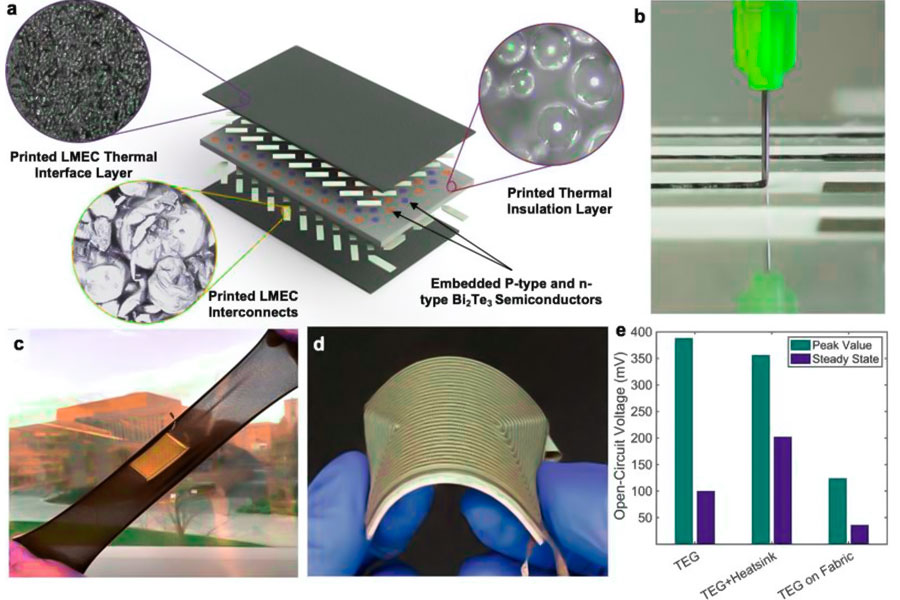

5.Formation of complex complex structures 6.Green manufacturing practices 1.Medical and Biotechnology Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc. JS technology association: 2.Automotive and Aerospace Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades). JS technology association: 3.Education and research Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development. JS technology association: 4.Industrial manufacturing Application scenarios: Mold inserts, fixtures, automation equipment components. JS technology association: Real-time application analysis of JS Consumer electronics industry: Cooling components for smart wearables Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces. Technical difficulties: JS company solution: 1.Process selection 2.Design optimization 3.Quality control 4.Technical highlights 5.Achievements 1.Material innovation New high-performance metal alloys: Breakthroughs in biocompatible materials: Expansion of Composites Applications: 2.Technological breakthroughs 3.Extension of application In the medical field: Aerospace: 4.Sustainable technology 5.Frontier exploration 1.Automated process upgrades 2.Intelligent scheduling and resource management 3.Innovations in materials and processes 4.Standardization and lean production 5.Energy and equipment maintenance management The application of 3D printing technology has pushed the boundaries of traditional manufacturing, from lightweight smart wearable devices in the consumer electronics industry to precision parts maintenance and complex structural innovations in industrial equipment. Not only does the technology shorten product development and reduce customization costs, it also provides unprecedented solutions for the industry through the diversity of materials and process flexibility. A pioneer in 3D printing technology, JS is driving the transition 3D models printing from prototype validation to mass manufacturing with its high precision processing capability (e.g. ±0.005mm tolerance), multi-material compatibility and intelligent manufacturing processes. Whether personalized prosthetics in the medical field or abrasion-resistant coating repairs for industrial devices, 3D models printing is redefining manufacturing possibilities. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.How to use 3D printing to customize prosthetics in the medical field? Through medical scanning modeling, biomaterial 3D printing and other methods, personalized prosthetics are designed to meet patients' needs accurately. 2.Can 3D printing produce complex mechanical parts? By using SLM and other technologies, complex metal parts such as aircraft engine blades and automobile transmission components can be manufactured directly, breaking through the limitation of traditional technology. 3.What parts can be 3D printing for cars? Cars can be 3D printed with lightweight components such as brackets and gears, interior parts, prototypes and tool fixtures to improve design freedom and productivity. 4.How can 3D printing help with school teaching? 3D printing supports students to build hands-on models, visualize abstract concepts, improve practical skills, and think creatively.

3D印刷の基本的な定義は何ですか?

グローバル3D印刷市場はどのように発展していますか?

year

市場規模(数十億米ドル)

年間成長率(CAGR)

コア成長領域

重要な駆動因子

2022

240

15.3%

航空宇宙、医療、自動車。

金属3D印刷モデルの需要が爆発しました。

2023

276

15.3%

金属印刷、歯科モデル。

印刷サービスのプロモーション

2025

375

16%

インテリジェントな製造、建築モデル。

マルチマテリアル3D印刷モデルのブレークスルー

2027

500

15.3%

バイオプリントおよびパーソナライズされた消費者製品。

クラウド印刷サービスの拡張。

エリア

2022年の市場規模(数十億米ドル)

メイン成長ドライバー

北米

90

航空宇宙および自動車製造。

ヨーロッパ

75

医療インプラント、建物モデル。

asia-pacific

60

電子製品、歯科カスタマイズ。

他の領域

15

教育と文化的および創造的な製品。

3D印刷の課題と制限は何ですか?

3D印刷はプロトタイピングにどのように使用されていますか?

What industries are currently covered by 3D printing technology?

What are the latest developments in 3D printing technology?

How can JS achieve a 15% efficiency improvement in 3D printing?

インジケーター

JS scheme

Other printing shops

Efficiency improvement

Equipment preparation time (single order)

8 minutes

20 minutes

+60%

Post processing time (per piece)

12 minutes

30 minutes

+58%

インジケーター

JS scheme

Other printing shops

Efficiency improvement

Equipment utilization rate

82%

65%

+26%

Order delivery cycle

4.5 days

5.5 days

+18%

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線:1px;境界線:#000000;" border = "1">

インジケーター

JS scheme

Other printing shops

Efficiency improvement

Material switching time (single order)

3 minutes

15 minutes

+80%

Single layer printing time (SLA)

3 seconds

6 seconds

+100%

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線:1px;境界線:#000000;" border = "1">

インジケーター

JS scheme

Other printing shops

Efficiency improvement

Clamping time (single order)

5 minutes

15 minutes

+67%

Novice training cycle

1 day

3 days

+67%

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線:1px;境界線:#000000;" border = "1">

インジケーター

JS scheme

Other printing shops

Efficiency improvement

Equipment downtime

2 hours/week

5 hours/week

+60%

Unit energy consumption cost

$0.8/hour

$1.2/hour

+33%

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources

JS

迅速なプロトタイピングと迅速な製造専門家

CNC加工、3D印刷、ウレタン鋳造、迅速なツール、射出成形、金属鋳造、板金、押し出しを専門としています。

タグ:

共有します

Criticism

0 comments

Click to expand more

Featured Blogs

No data