Think about the high-end drone in your hand, which is light but extremely strong, or the automotive engine parts we designed, which can still operate reliably under high temperature and high pressure. The key step behind this is actually determined at the start of the project: which metal alloy did we choose?

In the field of high pressure casting, light metals such as aluminum, zinc, and magnesium are the absolute main force. They are light in weight and have good fluidity, which are particularly suitable for efficient molding of complex and precise parts. Although steel and iron can also be die-cast, they are usually used in special scenarios with more extreme requirements.

Choose aluminum, zinc or magnesium?

This is by no means a casual decision. Each material has distinct characteristics: magnesium pursues extreme lightweight, zinc has outstanding toughness, and aluminum is relatively balanced in strength, heat resistance and processability. If you choose the right one, the product performance will have a solid foundation. If you choose the wrong one, the parts may have problems in strength, heat resistance or molding, which is not cheap.

It can be said that material selection is one of the lifeblood of the success of high pressure casting projects. Today I will talk to you about how we view the selection ofdie-casting materials in JSand how to get this crucial question right.

Core Answer Summary:

| Material type | Main advantage | Typical application examples | Material costs |

| Aluminum alloy | The best overall performance (strength, weight, cost). | Automotive components, 5G communication housing, power tools. | Medium. |

| Zinc alloy | The best precision and surface treatment performance. | Precision connectors, bathroom hardware, decorative parts. | Low (but high specific gravity). |

| Magnesium alloy | The lightest structural metal with excellent shock absorption and shielding performance. | Laptop casing, camera body, drone frame. | Higher. |

This article will answer your questions:

- In this guide, I will share the three most commonly used alloys for high pressure casting and their respective material properties.

- Then, let's talk about the often overlooked key role: special steel for aluminum high pressure casting mold.

- Finally, using a real medical device case, we will disassemble how choosing the right material can improve product performance and reduce costs.

Why Trust This Guide? Practical Notes from JS's Front-Line Engineers

Whenever a drawing of analuminum high pressure casting partis delivered to us, our JS material engineer team will automatically start a series of key considerations:

- How high a temperature can it withstand?

- Does it need to shield electromagnetic interference?

- Is the surface sandblasted and oxidized or simply painted?

Because at JS, we know that the considerations behind choosing A380 aluminum alloy for car engines and AZ91D magnesium alloy for drone frames are completely different. The selection of mold steel and how to perform heat treatment are directly related to whether the expensive molds invested by customers can stably produce hundreds of thousands or even millions of qualified products.

I remember a customer who made marine electronic equipment. Their initial design used an aluminum alloy shell, but it always had problems in the salt spray environment. After analysis, we changed the material from aluminum to a special zinc alloy. Not only did we change the material, we also optimized the mold design at the same time. Taking advantage of the excellent fluidity andsurface finish of zinc alloy, the product's ability to withstand salt spray corrosion has tripled!

Even better, zinc alloy has a good electroplating effect, which directly cuts off a costly secondary coating process, and the unit cost has dropped by 15%. "Understanding" the material properties is the daily work of our JS engineering team.

"I agree with Herbert Holloman's words: In any engineering design, material selection lays the foundation for 80% of the performance of the entire project, and it defines the boundaries of possibility. "

The bits and pieces shared in this guide are not empty theories, but all hard-core experience we have accumulated next to high-temperature die casting machines, in precision testing rooms, and through countless trials and errors and successes.

System 1: Parts Materials - The Final Form of Your Product

As a JS engineer, I deal with these metal materials the most every day. They are like partners with different personalities, and ultimately determine the appearance and capabilities of the product in your hands. I will share with you the three most commonly usedhigh pressure casting materials below:

Aluminum alloy - the all-round main force

Aluminum alloy is most used in die castingbecause it has the best overall performance. It is strong enough, light enough, not easy to rust, and has good thermal conductivity, and the cost is relatively reasonable.

Commonly used grades are A380, A360, and ADC12, which have good fluidity. Imagine that under high pressure, they can fill every corner of the mold quickly and smoothly like honey, especially suitable for high-pressure casting,a rapid prototyping process.

What are its powerful aspects?

The biggest advantage is that it is light and powerful, has a good heat dissipation effect, and can withstand a certain high temperature. Like part of the engine housing and gearbox housing on your car, as well as those parts of the 5G base station that need heat dissipation, and even the fuselage of many power tools, aluminum alloy high pressure casting parts may be used.

Zinc alloy - precision and surface expert

The strength of zinc alloy lies in the manufacture of precision and high appearance requirements of parts. It has a low melting point and excellent fluidity. It can drill into the thin and complex thin-walled structures in the mold, and it has less wear on the mold, so the mold can be used longer.

- Commonly used grades: Zamak 3, Zamak 5, ZA-8.

- Its core advantage is that the products have accurate dimensional accuracy andgood surface finish, which is very suitable for subsequent treatment such as electroplating and spraying. There is also a hidden skill: it can naturally shield some electromagnetic interference (EMI/RFI).

- Typical applications: Car door handles, bathroom hardware, precision plug and socket shells in electronic products, zipper heads and various decorative badges.

Magnesium alloy - the king of lightweight

Why is it the lightest? It is the lightest of our commonly used structural metals, about 33% lighter than aluminum and about 75% lighter than steel!

- Common grades: AZ91D, AM60B are the mainstream.

- Its outstanding advantages: the core is just one word, light! Extremely light. And it also has a special feature, good energy absorption and shock absorption effect, and strong electromagnetic shielding performance.

- Therefore, those who pursue the ultimatelightness and thinness of laptop shells, advanced camera bodies, drone frames, and the skeleton inside the steering wheel of the car, the dashboard bracket, which must be both light and a little tough, magnesium alloy is the first choice.

Aluminum, zinc, and magnesium are the three main materials for die casting, each with its own focus. Aluminum alloy is versatile and durable, zinc alloy is fine and beautiful, and magnesium alloy pursues extreme lightness.

"At JS, we focus on understanding the characteristics of these materials and can help you match the most suitable high pressure casting process solution. Optimize performance and cost. If you have any questions about the material selection of your die casting project, feel free to talk to us. We are always ready to use the most suitable metal to cast the core competitiveness of your product."

System 2: Mold Material - The Hero Behind the Casting Precision

Now, let me talk in depth about the success of high pressure casting, the important role behind it, mold material. It directly determines the precision of parts and the life of molds. A set of molds must be able to withstand thousands or even tens of thousands of times of violent erosion of high-temperature molten metal and huge clamping force to ensure dimensional stability, no cracking, and no deformation. This is directly related to the return on your mold investment.

Mold steel: Core support under high temperature and high pressure

The working environment of thedie casting moldis extremely harsh: it must be repeatedly eroded by boiling molten metal at around 700°C (or even higher), and it must withstand hundreds of tons or even thousands of tons of clamping force. In this environment, ordinary steel will quickly soften, deform or crack.

What materials do we generally choose?

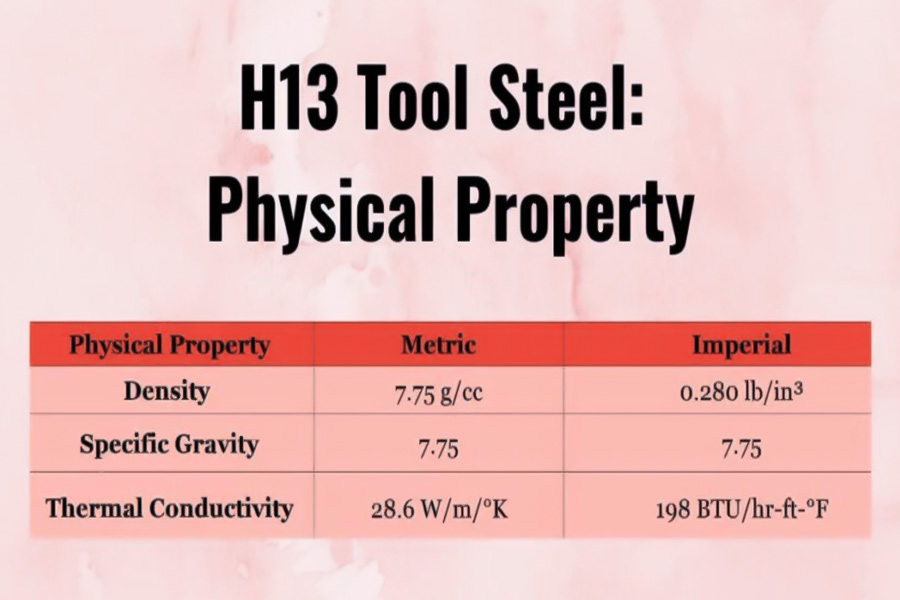

H13 steel is definitely a pillar-level existence in the industry.It has three excellent capabilities:

- Excellent high-temperature strength: At high temperatures above 600°C, it can still maintain sufficient hardness and strength to resist the erosion of aluminum liquid and deformation caused by pressure.

- Sufficient toughness: Strong ability to resist cracks caused by repeated heating and cooling cycles.

- Good balance: High comprehensive scores in hardness, toughness, and thermal fatigue resistance, durable, and relatively cost-effective.

A reliable and durablealuminum high pressure casting toolingmust have a core skeleton of high-performance hot working die steel such as H13. This is the basic guarantee for the mold's long lasting life.

Mold coating: Improve protection ability

Good steel alone is not enough. High-temperature aluminum liquid is particularly easy to stick to the mold (especially aluminum high pressure casting), and there will be a series of problems on the mold surface, which will lead to:

- Part surface defects (strain, sticking).

- The mold is difficult to remove, extending the production time.

- Premature mold failure.

This requires the use ofhigh-performance coatingsto form a super-hard, wear-resistant, low-friction and chemically inert protective layer on the mold steel surface.

The mainstream technology is PVD coating:This technology can accurately "plate" a thin layer of special materials on the mold surface.

What is the commonly used coating? Depends on the needs:

- Titanium nitride (TiN): Golden, versatile, mainly improves surface hardness and wear resistance, making the mold more durable.

- Chromium nitride (CrN): Silver-gray Chromium nitride (CrN): The most excellent function is to be resistant to aluminum alloy melt adhesion! Especially suitable for aluminum alloy high-pressure casting, it can effectively prevent aluminum liquid from sticking to the mold, saving worry and effort, and further reducing wear.

How obvious is the coating effect?

| Performance index | Uncoated mold steel | TiN coated mold steel | CrN coated mold steel | Lifting effect |

| Surface hardness (HV) | Approximately 500. | Approximately 2300. | Approximately 1800. | Increase by 3-4 times. |

| Abrasion resistance | reference. | Increase by 5-10 times. | Increase by 3-8 times. | Significantly extend lifespan. |

| Anti aluminum liquid adhesion | reference. | Moderate improvement. | Significant improvement. | CrN optimal. |

| Coefficient of friction | reference. | Reduce by 30-50%. | Reduce by 40-60%. | Smooth demolding. |

Source: ASM International - Handbook of Physical Vapor Deposition (PVD) Processing.

If the mold is not well made, no matter how good the part design is, it will be useless. Good mold = hot work die steel (H13 is the core) + coating (TiN wear resistance, CrN anti-stick aluminum).

"At JS, we know that the right choice of mold material and good use are directly related to the life of your mold, the quality of the part, and ultimately your cost. Die casting molds are not cheap, so don't let the material shortcomings hold you back. Do you have any questions about the mold? Welcome to discuss with us in depth and jointly optimize the solution to ensure that you get the maximum return on your mold investment."

Actual Combat Case Analysis: Choosing the Best Shell Material for Handheld Medical Scanners

Handheldmedical devices used by doctorsare really a big problem to design! It must be light enough so that doctors can hold it for a long time without getting tired. It must be strong enough not to break if it falls on the ground. The key is that it must protect the delicate electronic components inside tightly and not be interfered by the messy electrical signals from the outside world.

H3: Customer Challenge: Make a lightweight, strong and EMI-shielding medical device housing

A medical technology startup we worked with designed a great handheld ultrasound scanner and was ready to mass-produce the housing. They ran into trouble:

- Method 1-CNC machining: The precision was up to standard but the manufacturing cost was too high, which affected the final pricing competitiveness of the product.

- Method 2- Plastic injection molding: The strength was not enough, and in order to prevent electromagnetic interference (EMI), an additional layer of conductive coating had to be sprayed, which was expensive and troublesome.

- Method 3- Aluminum alloy solution (A380): Although thehigh pressure casting aluminum methodwas considered, it was indeed much stronger than plastic, but it was still a bit heavy in practice, and the doctor's hands would get sore after using it for a long time. It had EMI shielding performance, but the design had to be strengthened, which was not ideal.

JS solution: From aluminum to magnesium, one step at a time!

Our team carefully analyzed the customer's core needs: extreme lightness and inherent anti-interference ability. This immediately made us think of the strengths of magnesium alloy.

We gave our customers a bold suggestion: Don’t use aluminum alloy, try magnesium alloy (AZ91D)! The reason is very good:

- Lightweight breakthrough: The final finished shell is 33% lighter than the original aluminum alloy design, which effectively reduces the fatigue of doctors after long-term operation.

- Intrinsic EMI shielding: Magnesium alloy itself is a good anti-electromagnetic interference (EMI)! Using it as a shell, there is no need for additional spray coating or special structural design, and it can easilypass the EMC standardsof medical equipment such as IEC 60601.

- Design integration: We take advantage of the advantages of high-pressure casting to cast the internal structure that originally required multiple parts to be assembled directly on the shell at one time. The assembly steps are also saved, the weight is further reduced, and the cost is naturally reduced.

Comparison of the effects of the two solutions:

| Key indicators | Original plan (A380 aluminum alloy) | JS scheme (AZ91D magnesium alloy) | Effect improvement |

| Shell weight | Reference Value. | Reduce by 33%. | Significantly reduce operational fatigue. |

| EMI shielding capability | Basic compliance (needs to be enhanced). | Intrinsically excellent, no need for enhancement. | Save on shielding coating/structural design costs. |

| Structural complexity | Multi component assembly. | Integrated die-casting molding. | Reduce components, simplify assembly, reduce costs and increase efficiency. |

| Unit price of materials | - | High material cost | Comprehensive cost reduction of 12%. |

Results: Achieve a double breakthrough in performance and cost

As soon as the product was made, customers and doctors were pleasantly surprised! The shell is almost as light as plastic, and it is comfortable and reliable to hold in the hand. This has become one of the biggest selling points of the product.

Project achievements:

- The weight of the whole product is reduced by 25%, improving user experience and competitiveness.

- The overall cost of a single piece is reduced by about 12%, and the effect of eliminating shielding coating and simplifying assembly has overwhelmed the high unit price of the magnesium alloy material itself.

- The material solution passed all certification tests at one time, and the product was released 3 months earlier than originally planned.

Theselection of materialsis not based on whether the unit price is expensive or not, but whether it can perfectly match the product's usage scenario and bring out all the characteristics of the material. This case is the best proof: on the surface, magnesium alloy is more expensive than high-pressure cast aluminum, but the lightweight, natural anti-interference, and simplified design it brings ultimately make a better product.

"If you are also worried about the performance, weight or cost of the device's shell, don't just focus on traditional solutions, let's talk and see if our JS material solution can bring unexpected breakthroughs!"

FAQ - Answers to Your More Questions about Die Casting Materials

What are the most commonly used high pressure casting materials?

In the field of high-pressure die casting that we deal with daily, aluminum alloys are definitely the main players, especially models like A380 and ADC12. They have balanced and reliable performance, good casting fluidity, sufficient strength, and the key is that the price is also reasonable. Because of this, nine out of ten die castings on the market are made of this type of aluminum alloy.

Why can't steel be used for high pressure casting?

This is indeed a frequently asked point. The core problem is that the melting point of steel is too high. Molten steel usually needs to be heated to 1400-1500°C to melt, and the mold steel we use for high-pressure casting cannot withstand such extreme high temperatures.

Imagine: The hot molten steel is pressed into the mold at high speed, and the mold itself will be melted or severely damaged, and stable production is impossible. Therefore, the high pressure casting technology is naturally more suitable for materials with much lower melting points, such as non-ferrous metals such as aluminum, magnesium, and zinc.

Do die castings themselves need coatings?

It depends on where they are used. Although aluminum high pressure casting parts have good performance, they often need surface treatment to meet different needs.

- For example, if you want various colors or better weather resistance, we will powder coat it. If corrosion resistance or some special appearance effects are required, anodizing is also a good choice.

- Zinc die castings are more suitable for electroplating, such as chrome plating and nickel plating, which can produce very beautiful mirror effects and are also super wear-resistant. Therefore, whether to add coating or not depends on what environment your part will face and what additional performance or appearance is required.

Summary

I have been working in the field of high pressure casting for more than ten years, and I know that selecting materials is not as simple as picking a metal at random. This is a real technology! The real power lies in the fact that you have to build a complete set of alloy materials + mold steel + surface treatment combinations for the specific needs of your product.

Whether you can fully understand this combination is the key to the gap between thebest high pressure casting companyand ordinary processing plants. If you choose the right one, the performance, life and cost of your parts will be truly guaranteed!

Take action, don't hesitate!

Don't waste precious development time on trial and error! Your project deserves an optimal solution. Leave it toour JS engineering teamfor in-depth support:

- In-depth assessment of your product needs.

- Combined with our rich material library and process data, we will develop a dedicated solution for you.

- From the initial material selection, we will protect your mold investment and long-term mass production stability.

Please upload your drawingsand get a clear quotation report.In this report, you can see not only the price, but more importantly, JS's professional suggestions and supporting logic for key material selection.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource