Surface finishingis a widely overlooked link. It lies behind the product's shiny appearance and governs the core performance and experience.

Think of these headaches: the parts you have designed are dimensionally accurate, but they are wasted and worn out due to excessive friction as they are being assembled. Your top-of-the-line electronic products with excellent looks have fingerprints all over their surfaces when touched by consumers, and the cost drops right away. The reasons for these headaches are usually that the surface processing is not good.

It is not as easy as the previous beautification process. Automobile parts' wear resistance, medical equipment's corrosion resistance, bonding strength between metal, and mobile phone shell's touch all rely on surface treatment. It is as if wearing an invisible smart coat to the product, not only looking good but also functional.

Don't underestimate it!While the consumer may not notice it, the finishing quality on the surface directly affects product life, reliability and customer satisfaction.

Give a real-life example: in theautomotive industry, more than 80% of recalls are because of surface defects! Isn't this sufficient to demonstrate the issue? Whether it is to make mirror gloss or matte feel, to improve rustproof function or to ensure adhesion of the coating, surface treatment is a crucial core technical link in precision manufacturing. It determines if the products manufactured by us are just usable or rather easy to use and durable.

Core Answer Summary:

| Processing purpose | Common Process Examples | Central role |

| Enhance aesthetics | Sandblasting, polishing, anodizing, painting. | Change color, luster, and texture to enhance a sense of sophistication |

| Enhance performance | Hard anodizing, hard chromium plating, nitriding. | Improve hardness, wear resistance, and corrosion resistance |

| Change function | Gold plating, silver plating, passivation. | Enhance conductivity, weldability, and biocompatibility |

This article will answer your questions:

- In this guide, I will define for you what surface treatment is.

- I will show you how to read the surface roughness markings on engineering drawings.

- Then I will outline the most usedmetal surface finishing techniques.

- Combined with a real-life selection problem, how to balance performance requirements, aesthetic effects and production costs, use real cases to explain how to choose.

- Finally, use the Q&A session to answer specific questions you may encounter.

Why Must You Trust This Guide? JS's Real-World Practice in Surface Treatment

We don't just process parts in our JS company. What we offer is the finished product that customers can now acquire and use.The subtle details of the surface treatment process are exactly those we discuss.

- For example, if you want your mobile phone cover to be as smooth and brittle as Apple phones, what coarse sand and fine sand are you supposed to spray? We do.

- And for the medical implant electrolytic polishing to be implanted in the human body, how to choose parameters to make it smooth and safe so that the body would not reject it? It is also a question we ponder day after day.

Wehelp you solveall the component problems from inside out, from dimensional accuracy to the final appearance and feel. Speaking of experience, none of the recommendations in this guide come directly from books, but rather summarized after we've helped customers resolve hundreds of problems.

- Has the customer encountered the problem of the color being darker and lighter in some areas after anodizing? That's because of the non-uniform film thickness, and we've overcome it.

- The product of the client failed the salt spray test and rusted? The problem is that the coating was not selected appropriately at the beginning, and we experienced the same thing.

Every one of the words you are reading here is our field experience gained from repeated trials in the lab and continuous testing in the workshop, sweat and money. It is not an empty theory but a proven method tried hundreds of times.

"Quality master Philip Crosby emphasized: Quality is not defined by inspection but built and made right from the beginning."

The primary aim of this guide is to allow you to carry out the surface treatment at the manufacturing and design root, remove possible hazards, and improve product quality and dependability.

Interpreting the Language of Engineers: Surface Roughness

For us engineers, smoothness is not just a feeling. It is a key parameter that can be accurately measured and clearly written in black and white, which issurface roughness.

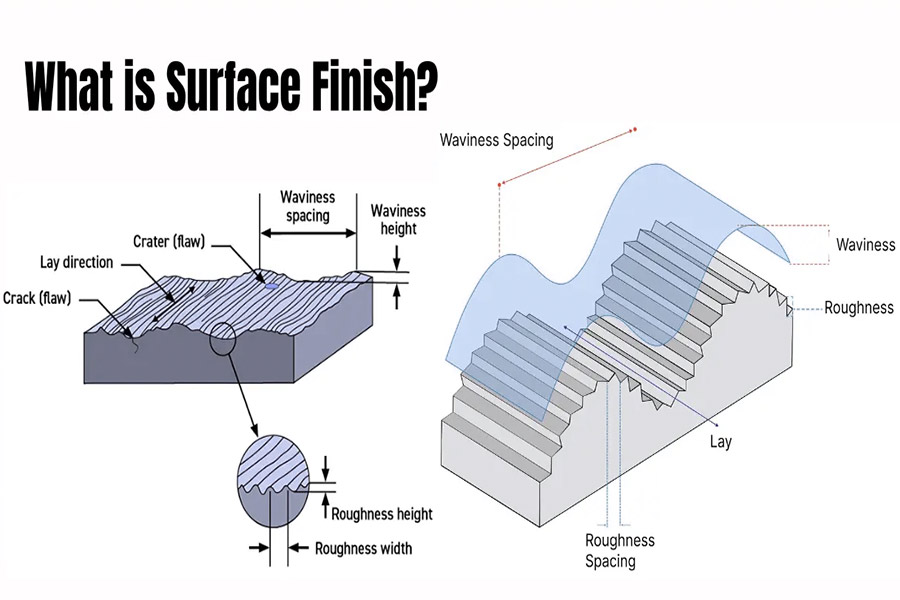

What is surface roughness (Ra)?

Simply put, Ra (Roughness Average) is the core indicator to measure how "rough" or "smooth" a surface is.

Imagine: Even if the metal surface looks smooth, it actually looks like a miniature mountain when you zoom in, with "peaks" and "valleys".

How to measure Ra?It is measuring the average height from these "mountains" down to the "valley bottom."

Numerical significance:The smaller the Ra value, the smaller the peaks and valleys, and the flatter and smoother the surface.

For example:

- Ra 3.2 µm: It feels like a compacted dirt road, with a sense of ups and downs.

- Ra 0.8 µm: It's like a flat asphalt road, much smoother.

- Ra 0.1 µm: That is absolutely the ultimate smoothness of the top F1 track level.

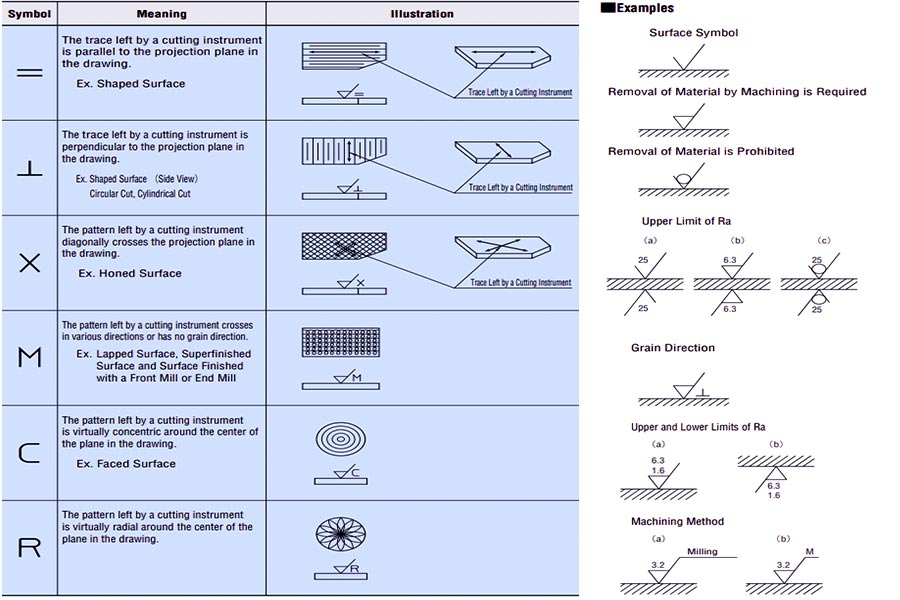

How to read the surface treatment symbols on the drawings?

- The "check mark" sign (√) on the blueprints is the specification for surface roughness. The critical information is hidden in the following places:

- Ra value (key!):The number written inside the "check mark", such as 3.2, means the maximum allowable roughness (the Ra value cannot exceed it).

- How to process?: The text on the horizontal line above the "check mark" tells you what process to use to achieve it, such asmillingand grinding.

- How to measure the length? : The number to the right (or below) of the "check mark" indicates the sample length (sampling length) selected during measurement.

- Which direction is the texture facing? : The small symbols under the "check mark", such as = (parallel), X (cross), M (multi-directional), indicate the direction of the surface texture.

How smooth can different processes make it? (Common Ra value range)

The process you choose largely determines how smooth the surface can be. Let's take a look at our common ones:

| Processing technology | Typical Ra value range (µm) | The feeling of looking/touching |

| Casting | > 12.5 | It is clearly rough, with visible sand holes and granular texture. |

| Milling | 1.6 - 6.3 | You can see/feel the knife marks one by one. |

| Turning | 0.8 - 3.2 | There are very fine spiral patterns, smoother than milling. |

| Grinding | 0.2 - 1.6 | It's quite smooth, with some directional fine lines. |

| Polishing | < 0.4 | Very bright, advanced can achieve mirror effect. |

"Understanding surface roughness Ra and drawing symbols is a key step to ensure the performance and appearance of parts. Don't let roughness become the shortcoming of your product! At JS, we deal with these details every day. Want parts that are both easy to use and good-looking? Send us the drawings and let us use our practical experience to help you choose the right process and control the quality from the source."

Mainstream Surface Finishing Process Tour

There are many ways to treat the surface, just like our engineer's toolbox. Each tool has its best treatment method. The key depends on what effect you want the part to achieve.

Category 1: Subtractive method-making the surface smoother

This is to grind the surface or remove a layer to make it smoother, more uniform or to create a specific texture:

- Sandblasting/shot peening: Strike the part's surface with high-speed sand or small steel shots. The effect is to make a uniform matte surface, and it can also release the stress inside the part to make it stronger. I often use it to make appearance parts or clean the surface.

- Polishing/grinding: The goal is to pursue the ultimate smoothness! From machine polishing to more advanced chemical mechanical polishing, the core idea is to grind layer by layer to minimize the surface pits (Ra value) and make it shiny or even like a mirror. Watch cases and high-end decorative parts are inseparable from it.

- Wire drawing: This must have been seen by everyone. The texture of manyhome appliance panelsis to use a sanding belt or brush to "draw" straight lines on the surface in a specific direction, which looks very textured.

Category 2: Additive method - put "clothes" on the surface

This process is to put an extra layer of material on the exterior of the part, mostly for protection, appearance or to create new function. In the common plating and surface finishing operation:

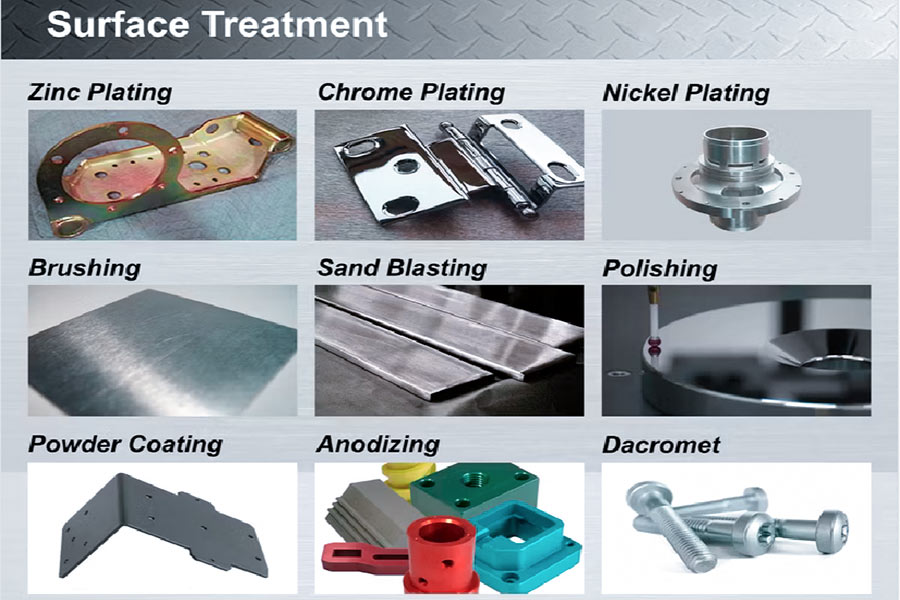

- Electroplating: Immerse the part in a solution of metal and pass an electric current to plate a thin layer of metal film continuously on the surface. For example, nickel plating is anti-rust, chrome plating is glossy and wear-resistant (like a car bumper), and gold/silver plating is mainly for conductivity. We often use it to make connectors and ornamentation parts.

- Anodizing (for aluminum): It's the "exclusive armor" for aluminum and its alloys. Through the electric treatment, a hard and dyeable oxide film "grows" on the surface of aluminum. It's colorful, corrosion-proof and wear-resistant. We use the process on many consumer electronics and automobile components.

- Spray painting/powder spraying: The most popular, maybe. Spray painting is spraying liquid paint, and powder spraying is spraying charged plastic powder (statically adsorbed and then baked). It is of high color variety and good protection. From cars to washing machines, everywhere. Most utilized inour workshop is powder spraying, which is cost-efficient and also eco-friendly.

Category 3: Conversion method - modifying the surface itself

This is not an additive or subtractive method, but modifies the surface material's properties:

- Passivation (stainless steel): Use a special acid to wash away the remaining iron filings on the surface so that the natural, super rust-proof chromium oxide thin film on the stainless steel surface is more compact and perfect, and the rust-proof property directly reaches a high level. You need to pass this level for the production ofmedical devicesand food-grade equipment.

- Blackening/phosphating (mainly for steel): Blackening forms a thin black oxide layer on the surface of steel, and phosphating forms a phosphate crystal layer. The main function is to prevent rust, and it's a great primer for subsequent painting, making the paint stick better. The majority of black bolts and tools you see are blackening treated.

- Heat treatment (surface hardening): For example, nitriding and carburizing. It's not just heating, but putting the parts in a special atmosphere to heat them. Allow these materials "drill" into the surfaces with parts and change the "physique" of the surface. The purpose is to make the surface of the parts particularly hard and wear-resistant, but the core must be tough. Gears and shafts, which bear severe friction, all rely on it.

"Prof. Mike F. Ashby, an authority on material selection, emphasized that the selection, processing and surface treatment of materials should be regarded as a whole, which is a collaborative path to achieve product function, beauty and reliability. "

The choice of surface finishing process depends on the functional requirements, appearance requirements and use environment of the parts. JS focuses on material surface technology and provides professional research and judgment. Please provide us with your specific needs and part drawings. We will combine our experience to recommend the most suitableprocess solutionfor you to ensure that the parts have reliable performance and meet the appearance standards in one step.

Actual Case Analysis: Surface Treatment Decision of a High-End Drone Bracket

Surface treatment does not mean choosing a process. It is more like building blocks. It is necessary to combine different "building blocks" (processes) according to the needs of different parts of the parts to achieve the most perfect effect. The following drone bracket case is particularly illustrative of this truth.

Customer challenge: It must be good-looking, durable, light and cost-effective

We have a customer who wants to make an aluminum alloy (6061-T6) bracket for a professional aerial photography drone. The requirements are not simple:

- High appearance: It must be of high-quality matte black and must be exactly matching the body design.

- Must be durable: It often flies outdoors, exposed to wind and rain, and must be scratch-resistant and corrosion-resistant.

- Key parts must be wear-resistant: The inner hole connecting the bracket and the gimbal is frequently active, so it must have low friction and be super wear-resistant, otherwise it will become loose in a short time.

- Costs must be controlled: This is something that needs to bemass-produced, so it can't be too expensive.

JS's trick: partition processing and solve it step by step

The initial plan encountered contradictions:

- Problem 1: If the entire bracket is hard anodized, the wear resistance of the inner hole (HV500+) is absolutely satisfied, but the overall appearance is dark gray, not the pure matte black that customers want, and the cost is very high.

- Problem 2: If only ordinary sandblasting + black anodizing is done, the appearance is matte black, and the cost is also reduced, but the hardness of the inner hole is not enough (ordinary anodizing is about HV300), and it can't withstand the daily friction of the gimbal.

The above two solutions are not feasible, what to do?We used our deep understanding of surface finishing tools to optimize the combination scheme:

Step 1: Overall sandblasting

After theCNC machinedbracket, first perform 150# glass bead sandblasting on the whole. This step makes the surface of the entire part even and delicate, laying the foundation for the subsequent matte effect.

Step 2: Protect the key parts

Use a special high-temperature resistant rubber plug to accurately protect the inner hole that requires wear resistance. This step must be accurate and leakage must not happen.

Step 3: Get the color appearance

Now, do ordinary black anodizing for the bracket. Because the inner hole is protected, the oxidation liquid cannot enter, so only the outer surface turns black. We control the thickness of the black oxide film to about 15µm, so that we can get the high-grade matte black appearance that customers want, and the cost is in line with expectations.

Step 4: Local hard oxidation

Carefully remove the protective rubber plug of the inner hole and perform hard anodizing on this inner hole alone. This step makes the oxide film thickness on the inner hole surface reach more than 40µm, the hardness exceeds HV500, the wear resistance is very good, and the gimbal friction problem is perfectly solved.

Final result: Use the combination solution to achieve the effect of 1+1>2

Take a look at the real benefits brought by this combination solution:

| Index | Single process plan | JS combination scheme | Advantages reflected |

| Appearance | Hard oxidation appears as dark gray/bright gray, which does not meet the requirements. | High grade matte black, fully satisfying the design. |

Enhance the aesthetic value of the product.

|

| Wear resistance of inner hole | The ordinary oxidation hardness is insufficient (about HV300). | Hard oxidation, hardness>HV500, excellent wear resistance. | Significantly extend the lifespan of core components. |

| Comprehensive cost | The cost of fully hard oxidation is high. | The cost of the combination plan is reduced by about 20%. | Significantly enhance market competitiveness. |

Core revelation:

This case teaches us that excellent surface finishing engineering is not about "ordering a dish" from the menu, but like an old Chinese doctor prescribing a prescription, the "symptoms" (demands) of different parts of the parts are determined, and then a precise "combination prescription" is prescribed. This relies on the understanding of various processes and the practical experience accumulated in the workshop.

"Surface finishing engineeringis a key link in determining product performance and appearance. Faced with complex requirements, JS is good at using a combination of processes to achieve the best results at the best cost. Want your key components to be both reliable and outstanding? Send us your part drawings and performance requirements immediately, and the JS engineering team will customize a surface treatment solution for you."

FAQ - Answer Your Surface Treatment Questions

Which is better, anodizing or painting?

In fact, there is no simple "better", the key depends on what your parts need.

- Anodizing is mainly for aluminum parts. It is to form a hard film on the substrate. It has super strong bonding, extremely wear-resistant, and more metallic texture, but fewer color options.

- Spray painting/powder spraying is to cover a layer of paint with extremely rich colors, which is suitable for almost any material and has high cost performance, but the coating is relatively easy to be damaged by bumps.

Which treatment method should I choose?

For extreme durability and metallic feel (aluminum parts), choose anodizing. For colorful appearance or non-aluminum materials, choose spray painting. There are other solutions in the field of plating & surface finishing (such as electroplating), and the final choice depends on your specific needs.

Why do my stainless steel parts still rust? Isn't it said that stainless steel will not rust?

Regarding the question of rusting of stainless steel parts,a key point needs to be clarified:

The nature of stainless steel is "relatively not easy to rust", but not "absolutely not rust".During processing or use, the surface may be contaminated with pollutants such as iron filings, or its natural protective oxide film may be destroyed. These damaged or contaminated areas will become the starting point of rust in humid, salty environments.

Therefore, for applications that require extremely high rust resistance (such as medical devices and ship parts), it is not enough to use stainless steel alone. Passivation treatment must be performed after processing. Passivation completely removes surface contaminants through chemical methods and causes the stainless steel surface to rebuild a denser and more stable chromium oxide protective film. This is a key step to ensure that stainless steel parts can play their due corrosion resistance.

Are "surface finish" and "surface roughness" the same thing?

As an engineer at JS, the difference between surface finish and roughness needs to be clarified:

The two are essentially stating the same attributes, but with opposite angles of expression.

- Surface roughness is a quantitative technical parameter that accurately measures the microscopic concavity and convexity of the surface through a specific value (such as Ra=0.8μm). The smaller the value, the smoother it is.

- Surface finish is a traditional qualitative concept, which uses grade symbols (such as ▽7) to vaguely describe the degree of smoothness. The higher the grade, the smoother it is.

In modern engineering practice, we prefer to use roughness markings with Ra values (such as Ra 1.6). This expression is more accurate, quantifiable, and in line with international standards, and can avoid processing errors caused by vague grade definitions.

Simply put: Roughness is expressed in numbers, smoothness is expressed in symbols, and digital roughness is the universal language of current engineering communication.

Summary

Surface finishing is far from being an optional link at the end of the manufacturing process. It is a core engineering element that requires strategic consideration at the beginning of product design. It directly determines the product's appearance appeal, functional reliability, service life and overall cost-effectiveness. Mastering and optimizingsurface finishing processesis a key capability to create excellent products.

Are you worried that improper surface treatment will weaken the value potential of your product?

At JS, we have complete surface finishing equipment and deep engineering accumulation. From CNC finishing,sheet metal forming, to final surface treatment, we provide one-stop service. We are a technical surface finishing equipment company and a partner to help you solve problems.

Take action now:

- Upload your design: Let us evaluate how to "customize the coat" for your parts.

- Get an expert solution:JS engineerswill recommend the best surface treatment combination based on your performance, appearance and cost requirements.

- Receive a clear quote: Quickly obtain a comprehensive manufacturing quote covering processing and surface treatment.

Let us work together to ensure that your products are of quality, inside and out.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com