Why do some products' soft-glue grips fall off and crack after long-term use, while others can stick to the hard plastic shell tightly, as if they were born as one? In fact,the key is not the glue, but a core choice before overmolding begins: material pairing.

What is overmolding? Simply put,the overmolding processis to wrap a different material (usually soft glue) on the hard plastic substrate. This is not simply gluing two layers of plastic together. It requires the soft glue to melt at high temperature, tightly wrap the substrate, and then rely on the physical bite or even molecular bonding between the materials to stick together. If the adhesion is good, the product will be strong and durable. If the adhesion is not good, it is easy to cause problems.

Therefore, choosing the right material combination is absolutely the key to overmolding! It is far from enough to just look at the performance of a single material. It is necessary to ensure that the substrate and the soft glue (such as the commonly used TPE) that is coated are in tune with each other. They must be able to stick together at high temperatures and can truly merge into one after cooling.

In our JS laboratory,one of the core tasks is to repeatedly test and screen various material combinations to ensure that each overmolding can achieve the best combination effect and final product performance. This is the secret behind those products that are comfortable to the touch and durable.

Core Answer Summary:

| Core concepts | Description | Why is it important |

| Substrate | The first layer of hard material is usually a structural component (such as ABS, PC, Nylon). | It determines the basic strength and shape of the product. |

| Overmold coating material | The soft second layer material is usually a functional/tactile layer (such as TPE, TPU, LSR). | It determines the grip, sealing, and aesthetics of the product. |

| Chemical bonding | The two materials attract and fuse with each other at the molecular level, forming the strongest binding force. | It is the preferred goal for achieving high-quality secondary injection molding |

| Mechanical interlock | By designing structures such as grooves and through holes, the two materials are physically "locked" together. | It is a necessary supplement or alternative solution when materials are incompatible. |

This guide wants to share our accumulated practical experience with you:

- We will provide a practical material combination reference table (this is a common tool in the industry).

- Focus on analyzing the most commonly used plastic overmolding combinations.

- We will also explain in detail the unique characteristics and requirements of silicone overmolding.

- The ultimate goal is clear: To help you accurately select the most suitable overmolding plastic material.

Why Trust This Guide? From The Perspective of JS Material and Process Experts

As an engineer responsible for material and process development at JS, I know that in the field of overmolding (secondary injection molding), material selection decisions are crucial. The value of this guide is rooted in our team's deep practical experience.

"James Hendry, a recognized authority on injection molding in the industry, once emphasized: Materials are the starting point of the process and the cornerstone of product performance. This is particularly reflected in the field of overmolding that we focus on."

At JS, based on countless projects, we have summed up a simple truth: whether a project can be successful,mold design accounts for 70%, and the remaining critical 30%is all bet on material science.

This is not just a casual remark. We have personally witnessed the painful lesson of customers who chose the wrong TPE material grade, resulting in the scrapping of the entire batch of products. We alsosolved the problem of the customer's soft rubber layerbeing easily peeled off at high temperatures by recommending a specific nylon substrate.

This experience is not gained out of thin air.Our team deals with the world's top material suppliers every day, and has actual performance data for hundreds of plastic and elastomer grades. More importantly, we know how to adjust the parameters on the injection molding machine to make the two materials really bite together.

The things in this guide are not theoretical deductions, but the core experience we have extracted with a little bit of practical experience after experiencing the joy of success and the lessons of failure.

The Golden Rule of Secondary Injection Molding: Compatibility Determines Everything

At JS, I deal with injection molding every day,especially overmolding vs insert molding. I deeply understand that if you want two different materials to be used on the same part for a long time,the key lies in whether the different materials can be combined for a long time. And the number one golden rule among them is material compatibility! This directly determines whether the product is strong and durable, or prone to cracking and delamination.

Whether the two materials can be tightly combineddepends mainly on two connection mechanisms:

1. Chemical bonding: "hands" between molecules

Principle:

Under the high temperature and high pressure conditions of secondary injection molding, the soft glue (such as TPE) covered will melt and slightly melt the surface of the substrate. At this time, the molecules of the two materials can penetrate, diffuse and entangle with each other. After cooling, they form a strong chemical bond connection at the interface, just like the molecules are tightly "holding hands".

What are the key considerations?

This mainly depends on the properties of the two materials:

- Polarity: Just like magnets are divided into positive and negative poles, materials with similar polarities are more likely to combine with each other.

- Melting point/processing temperature: The melting temperature of the soft glue must be appropriate, which must be able tomelt itself and slightly soften the surface of the substrate.

- Surface energy: The surface energy is well matched, so that the melt can better wet and spread on the substrate.

Benefits:This is the most ideal situation! The adhesion is super strong, and the parts often present an integrated appearance without obvious seams. Moreover, the requirements formold design are relatively simple and direct, and there is no need to deliberately make too many complex structures.

2. Mechanical interlocking: "mortise and tenon structure" in engineering

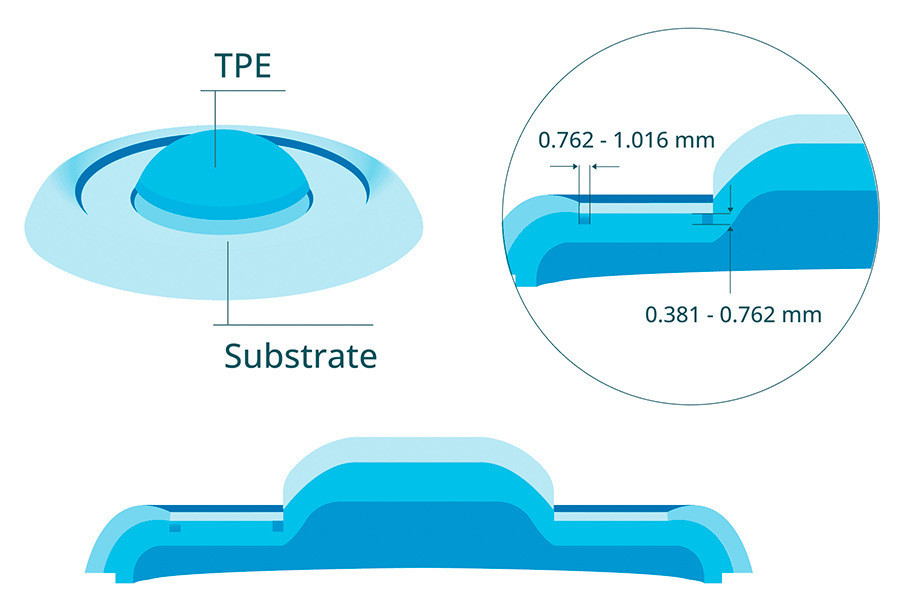

When the strength of the two materials is insufficient, or the chemical bond alone is not strong enough, we need to design the "mechanism" on the substrate in advance. These mechanisms can be small grooves, holes, specific rough textures, or even barb-shaped structures.

Then, during the secondary injection molding, the molten soft glue material will drill into these small holes and fill these structures. When the soft glue cools and hardens, it is physically "locked" in these structures of the substrate, just like an anchor hooking the seabed. If you want to separate them, you must destroy the material itself.

Where do we usually use it?

This method is a savior in many special cases:

- Use silicone (usually with poor chemical adhesion) to cover other materials.

- Coat plastic outside the metal insert.

- When two plastics really can't find a pair that can be chemically bonded.

"The key to successful overmolding is to effectively establish a connection between materials (chemical bonding, mechanical interlocking or a combination of the two), which directly affects product performance and quality. When selecting materials, we should not only look at the general category of materials, but also study the specific grade data and application experience in depth. For example, relying on mechanical locks requires collaborative mold design, and small batch mold verification is essential. JS welcomes discussions at any time to help you find the perfect material partner."

Secondary Injection Molding Material Pairing Guide

This table summarizes the typical combination performance of common hard substrates and mainstream cover materials (TPE/TPV, TPU, LSR) in the industry, and is an efficient tool for screening directions in the initial stage of the project. But remember:

- This table is only a general guide.

- The final combination effect will be affected by the formula, processing conditions and design of the specific material grade.

- The actual effect depends on the proofing!It is only used as a basic reference for project launch, not the final basis.

The following is the core pairing reference table:

| Substrate (hard) | TPE/TPV (thermoplastic elastomer) | TPU (thermoplastic polyurethane) | LSR (Liquid Silicone Rubber) |

| ABS | Excellent (chemical bonding) |

Good (chemical bonding)

|

Poor (requires mechanical interlock/primer) |

| PC (polycarbonate) | Excellent (chemical bonding) | Excellent (chemical bonding) | Poor (requires mechanical interlock/primer) |

| PC/ABS alloy | Excellent (chemical bonding) | Excellent (chemical bonding) | Poor (requires mechanical interlock/primer) |

| PP (polypropylene) | Good (requires special grade TPE) | Poor | Poor (requires mechanical interlock/primer) |

| Nylon (PA6, PA66) | Good (requires special grade TPE) | Good (requires special grade TPU) | Medium (requires special primer and mechanical interlock) |

| PBT | Good | Excellent (chemical bonding) | Poor (requires mechanical interlock/primer) |

| Metal (steel, aluminum) | Medium (requiring mechanical interlock) | Good (requires mechanical interlock) | Good (requires special primer and mechanical interlock) |

My interpretation of the grades in this table:

- Excellent:Strong chemical bonding can be generated between soft and hard materials. This is the most ideal situation, with high bonding strength and few design restrictions. This is the evaluation that our engineers like to see the most.

- Good: A certain chemical bonding can be generated, but the bonding strength is usually lower than the excellent level. I suggest that you add mechanical interlocking features as a supplement or insurance when designing the product to make the bonding more reliable.

- Medium: The chemical bonding is very weak or almost non-existent. Whether it can be successful depends mainly on the mechanical interlocking structure you design, which usually requires surface treatment, such as spraying a layer of treatment agent (primer) to improve the adhesion or protect the surface a little bit.

- Poor: It is difficult to form chemical bonding. The bonding strength must be achieved through a very precise snap-on structure design, and basically a specific primer must beused to treat the hard plastic surface.

From my bitter experience as a JS engineer:

(1)The specific material grade is the king!

This table is a general guide, but the performance of different manufacturers, or even different brands of TPE/TPU/LSR from the same manufacturer, may be very different!

Especially where it is marked "special grade required" (such as PP+TPE, nylon+TPE/TPU), you must ask for compatibility data and processing suggestions for specific brands from material suppliers like us orour JS's technical department.If you directly use this table to order materials, you may fail.

(2)Structural design is the soul!

Especially for medium and poor combinations, or even good combinations, a good and well-considered mechanical interlocking design is often the key to success or failure. Close communication with mold engineers and material engineers is necessary during the design phase.

(3)Proofing tests cannot be saved!

No matter how perfect the theory is, it must be tested in practice. It is strongly recommended that youuse the specific material brand you have selected to do a small sample test(such as a simple overlap test piece) to actually test the bonding strength before officially opening the mold. This step cannot be saved, as it can avoid big troubles later.

This table helps you to preliminarily screen the material combination and avoid obvious problems.The success of overmolding lies in three keys:precise matching of specific grades, targeted structural design, and strict sample verification.

"Don't make decisions based on the table alone! If you are evaluating a project, especially one involving difficult materials, we recommend that you contact our technical team as soon as possible. We will use professional overmolding injection molding technology to help you land the final product steadily!"

Common Material Combinations and Application Cases

Let me tell you about some of the most commonly used and most reliable material combinations in our actual projects, as well as their applications. These are all experiences that have been done and verified:

Case 1: The classic combination of mobile phone cases and tool handles: ABS/PC/PC-ABS + TPE/TPU

- Hard plastic + soft rubber solutions are widely used in parts such asanti-slip mobile phone cases, tool grips, and remote control button areas, and their advantages are significant:

- Functional complementarity: Hard plastic provides structural strength and good appearance, and TPE/TPU soft rubber provides comfortable touch, anti-slip properties, and cushioning and shock absorption.

- Reliable combination: The key chemical bonding makes the interface bonding between the two excellent, ensuring the long-term durability of the product.

At the same time,in rubber overmolding, this combination has also become one of the preferred solutions because of its excellent chemical compatibility, and engineers have high confidence in it.

Case 2: A strong choice for automotive and outdoor products: Nylon (PA) + TPE/TPU

Applications:Car door handle lining (comfortable grip), frequently plugged and unplugged connector interface (cable overmolding), outdoor parts that require flexibility and wear resistance.

Advantages:

- Nylon provides excellent wear resistance, chemical corrosion resistance and high temperature resistance, suitable for harsh working conditions.

- Specially formulated TPE/TPU soft rubber, covering the surface of nylon,provides a soft and elastic protective layer in contact, friction and sealing parts.

Key points:Although the combination is slightly more difficult than the previous one (it is necessary to choose the right special grade of soft rubber), once the match is successful, the effect and durability are very good.

Case 3: Medical and food grade safety guard: Silicone Overmolding

Application scenarios:The edge of the respiratory mask that directly contacts the skin, baby pacifiers, molds that require high temperature baking, and electronic products with strict requirements for waterproof seals (such as smart watches).

Why choose it?

Silicone (especially liquid silicone LSR), it is naturally non-toxic and odorless, meets medical and food grade requirements, is not afraid of extreme high and low temperatures, is not easy to react with other things, and is particularly soft and elastic.

Key reminder:

Silicone is chemically incompatible with most hard plastics, and it cannot stick firmly on its own! To achieve success, these two aspects must be addressed:

- Design a precise "snap-on" structure: Design barbs, grooves, etc. on the hard plastic parts so that the silicone can be physically locked after injection molding.

- Use primer well:Prime the hard plastic surface before injection molding.This layer of glue can act as a bridge to improve the adhesion between silicone and hard plastic. In the medical and waterproof projects we do, these two points must not be sloppy.

These successful cases provide reliable design directions. But the success or failure of the project lies in the details: precise material grade selection, optimized bonding structure design, matching primer and process.

"I usually recommend that when it comes to nylon or LSR combinations, it is best to consult our professional technical team in the early stages of the design. We will jointly determine the optimal material combination, review the structural design, and verify through small batch trial production to ensure that the product fully meets the standards in terms of function, durability and reliability."

FAQ -- Answers to All Your Questions about Material Selection

Question 1: What is the best secondary injection molding plastic?

To be honest, there is really no absolute best, and the product function and performance requirements need to be considered comprehensively.

- Pursuing good feel and cost-effectiveness:ABS is recommended as the substrate, coated with TPE soft glue. It can significantly improve the touch while effectively controlling costs.

- Require transparency and high impact resistance: PC hard glue substrate with coated TPU soft glue is an ideal solution, suitable for applications such as transparent anti-fall shells.

- Pay attention to wear resistance and chemical resistance: Nylon is recommended as the substrate, coated with TPE or TPU materials with wear resistance or chemical resistance.

- Medical applicationsor extreme temperature environments: Liquid silicone rubber (LSR) is an option, but its process requirements are high, and the substrate structure design needs to be carefully selected to match.

Question 2: What materials are used for insert molding?

This is answered in two parts:

- Insert material: usually metal parts (such as brass, stainless steel, aluminum alloy). Ceramic or printed circuit board (PCB) sheets can also be used. The insert is placed in the mold cavity before injection molding.

- Coating plastic selection:Commonly used materials include nylon (Nylon), PBT, PPS and other high-performance engineering plastics. The specific choice depends on the requirements for part strength, insulation performance, temperature resistance level, etc. For example, PPS coated metal inserts are often used for motor parts that require high-temperature electrical insulation.

Question 3: What material is the mold itself made of?

The main force is special steel: Steels such as P20, H13, and S7 are the absolute main force. They have high hardness or are strengthened by heat treatment, especially wear-resistant and impact-resistant, just to withstand tens of thousands or even hundreds of thousands of high-temperature and high-pressure plastic impacts.

What to do with small batches or proofing?

If we only make a few hundred or a few thousand samples, or the product is still in the verification stage, in order to save time and cost,we sometimes use 7075 aluminum alloy to make molds.Aluminum processing is fast, and the mold cost is much lower, but the life span is definitely not as good as steel molds. It is suitable for early verification or not mass production.

Summary

The key to ensuring a successful overmolding process is to have a deep understanding of the material properties. Choosing the right combination of materials not only ensures a strong and reliable product structure, but also significantly improves its market value and user experience. Although the compatibility chart is an important starting point, the most efficient way to truly optimize the design, achieve a strong bond and avoid risks is to work with experienced engineers.

Let the JS team light up your product with overmolding!

- Avoid expensive trial and error: When it comes to material selection, the experts of theJS team can help you choose the right material at the beginning of the project.

- Optimize design and bonding: We don’t just select materials, we can optimize your design to ensure the ideal bonding effect of the overmolded parts.

Get dedicated support now: Contact us and you will:

- Receive a free PDF of the Overmolding Design Guide (including practical principles).

- Speak directly with our engineers to discuss your project needs in depth.

- Find the ideal combination: Let’s work together tofind a material solution with the best performance and cost for your product.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com