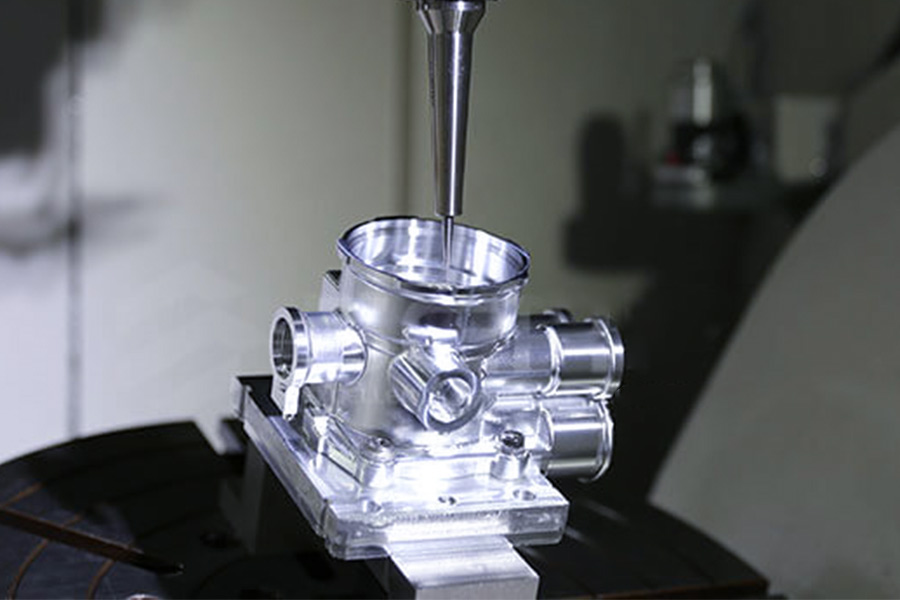

CNC milling is an innovative cutting method that relies on computer-controlled rotating cutting tools to remove excess parts from the surface of raw materials, ultimately obtaining the accurate shape and complex details required by the design. Unlike traditional manual milling methods, CNC milling can directly convert computer design drawings into actual processing routes.

This technology allows the entire production process to run automatically, the processing results are more accurate, and the quality of each batch of parts is basically the same. From the mid-20th century to the present, this technology has become a key technology for modern factories to produce various products, whether it is making sample models or mass production.

What is the main working principle of CNC milling?

CNC milling uses computer programs to control machine tools to complete processing tasks. The operator inputs the design drawings into the CAM software to generate G code, and the machine tool automatically performs cutting actions according to the code instructions. The tool is installed on the high-speed rotating spindle, the workpiece is fixed on the worktable and moves along multiple coordinate axes, and the target shape is cut through combined movements in different directions. This automated processing method can handle complex geometric structures and maintain high precision, and the processing accuracy can usually reach ±0.005 mm.

Our team of engineers optimizes tool paths and cutting parameters according to customer needs, provides precision CNC milling service, shortens production cycles while ensuring quality, and ensures that each part meets the dimensional tolerances and surface finish required by the drawings.

What are the main types of CNC milling machining? and their characteristics

CNC milling technology has developed a variety of specialized processing types according to the processing requirements and workpiece geometry, each of which has its own unique process characteristics:

1.Plane milling

It is also called slab milling and is the most commonly used type of CNC milling. This process is specifically used to process planes. It is divided into down milling and reverse milling according to the movement direction of the worktable and the material. In down milling, the tool rotation direction is the same as the feed direction, and in reverse milling, the direction is opposite. We use high-rigidity machine tools and special face milling cutters to produce extremely high flatness of the surface. Usually plane milling is used as the first process, and the reference plane is first processed before subsequent finishing.

2.Face milling

It is similar to plane milling, but with higher precision. The axis of the face milling cutter is always vertically aligned with the material surface. This tool is equipped with more blades than ordinary plane milling cutters. The blade in the middle position is responsible for finishing the surface, and the outer blades first cut off the excess material. Our company uses a special machine tool with a hydrostatic spindle for face milling. The surface processed is smoother than a mirror and reaches an accuracy of less than Ra0.4μm.

3.Straddle milling

This is a process that is specifically used to process pairs of parallel surfaces. We install two side milling cutters on both sides of the tool bar, clamp the workpiece and process two parallel surfaces at one time. This method saves time and ensures parallelism. We use computers to control the tool spacing, and guide rails and parts of different sizes can be quickly adjusted for processing. Workpieces that used to take 2 hours to prepare can now be started in 15 minutes.

4.Combined milling

This is a highly efficient method in CNC milling machining. Operators install milling cutters of different sizes on the same tool bar and process several planes of the part at the same time. We use an automatic adjustment system to control the speed and feed rate, which ensures quality and can cut metal quickly. We often use this method to process machine housings and parts with multiple grooves, and the efficiency is highest when making batches of more than 100 pieces.

5.Forming milling

It is used to process irregularly shaped parts. This process uses special milling cutters that can directly cut out fillets or concave and convex surfaces. JS can customize milling cutters of special shapes to cooperate with five-axis machine tools to process turbine blades and gears. Curved parts that previously required three clampings can now be processed in one go.

6.End milling

It is applied mainly to machine vertical surface and fine grooves. We use carbide milling cutters in deep grooving. Once the cutting parameter is set, the tool is hard to shake and iron chips are released smoothly. It is one kind of process that can be applied to machine heat sinks, and the vertical deviation of the groove wall does not exceed 0.02mm.

7.Angle milling

In CNC milling machining, this is specifically utilized to process bevels. The milling cutter is not cutting in the direction of the workpiece, but cutting it at an oblique angle. Our company's machine tool is equipped with an automatic angle adjusting mechanism, which can be clamped simultaneously with the turntable to process oblique holes and bevels. In processing the car gearbox's helical gear, the angle error is controlled within 0.5 degrees.

8.T-slot milling

It is divided into two steps. First, mill a straight groove with a usual milling cutter and secondly, widen the bottom with a T-type milling cutter. JS company offers an anti-shake handle for the tool and uses a step-by-step cutting method to solve the problem of vibration. After processing machine tool table's T-slot, the dimension error is 30% smaller compared to the usual method.

What is the difference between small CNC milling and five axis CNC milling?

Relying on the CNC machine tool precision standards and the American Society of Mechanical Engineers (ASME) 2023 Machine Tool Technology Report, along with JS's actual production data, the following analysis is drawn regarding the intrinsic differences between small CNC milling and five-axis CNC milling:

Technical parameter comparison

| Comparison items | 5 axis CNC milling | Small CNC milling |

| Typical processing dimensions | >1,000mm³ (capable of handling large complex parts). | <500mm³ (suitable for micro parts). |

| Spindle speed | 8,000-15,000 RPM (high torque). | 20000-60000 RPM (high speed). |

| Processing accuracy | ± 0.01mm (affected by axis linkage). | ± 0.005mm (micrometer level). |

| Number of axles | 5-axis (X/Y/Z+2 rotational axis). | 3-axis (X/Y/Z linear motion). |

| Tool Diameter | 3-50mm (standard/large cutting tools). | 0.1-6mm (micro tool). |

| Cost of equipment | $800 thousand to $5 million (industrial grade). |

$150 thousand to $500 thousand (compact model).

|

| Material removal rate | 100-500cm³/min (efficient rough and fine machining). | 5-50cm³/min (mainly precision machining). |

Core difference analysis

1.Structure difference of equipment

Small CNC milling uses a small machine tool structure, with a space of about 1.5 square meters, which is suitable for laboratories and small workshops. Our company's small machine tool is only 800kg, while the basic casting of the five-axis machine tool is 5 tons. The NHX6300 five-axis machine tool produced by German DMG MORI requires 6 square meters of installation space.

2.Comparison of processing capacity

In electronic connector processing by operators using small CNC milling, cutting depth is as high as 50mm. In five-axis machine tool processing of aircraft engine blades, 90° side wall cutting can be completed. ASME statistics show that five-axis processing of curved complex surfaces has 60% higher material removal rates compared to three-axis.

3.Precision control approach

When we equip minuscule CNC milling with a laser calibration module, we usually need to compensate thermal deformation errors. In micro sensor machining, the change of dimension is controlled at ±0.008mm. The five-axis machine tool utilizes a Renishaw probe as an automatic tool runout correction and the surface contour error of the artificial knee joint is ≤0.015mm.

4.Differentiation in application scenarios

The small CNC milling is applied in the medical industry to process dental implants, and its 1.5mm diameter threaded hole processing qualification rate is 99.2%. Five-axis machine tools are applied in aerospace enterprises to process titanium alloy wing frames, and the surface splicing gap is ≤0.03mm. Of the 152 products manufactured by the company in 2024, 68% of the small machines are used to create precision parts, and five-axis machines are mainly used to machine molds and complex structural parts.

How to distinguish CNC milling from composite machining CNC milling turning?

1.Distinctive processing methods

CNC milling is essentially applied with rotary tools to work on fixed workpieces, and it is best for cutting features such as planes, grooves, and curved surfaces. CNC milling turning combines turning and milling operations. The workpiece may be turned, and the tool carries out both milling and turning operations at the same time. It is most suitable for producing complex rotating components such as shafts, flanges, etc.

2.Different machine tool structures

CNC milling machine usually have three axes (X/Y/Z) or more linear motion axes, and the spindle fixes the tool. CNC milling turning composite processing machines are equipped with rotating spindles. The INTEGREX series of compound machines from Japan's MAZAK has a turning spindle speed of 5,000rpm, and the milling spindle is equipped with an independent drive module. When the operator processes the automobile gearbox housing, he first uses the turning function to process the outer circle, and then uses the milling cutter to process the flange surface.

3.Different applicable parts

CNC milling is suitable for processing non-rotating parts, such as molds, housings, etc. CNC milling turning is suitable for complex parts with rotating features, such as turbine blades, camshafts, etc. According to the German Machine Tool Manufacturers Association (VDW), compound machining can reduce the number of clamping times by more than 60% and improve accuracy by 30%.

Comparison between CNC milling and CNC milling-turning compound machining:

| Compare projects | CNC milling | CNC milling-turning |

| Number of motion axes | 3-5 axes. | 7-axis (including turning spindle). |

| Typical parts | Mold/structural components. | Rotating composite components. |

| Machining accuracy | ±0.01mm | ±0.005mm |

| Number of knife changes | 8-15 times/piece. | 3-5 times/piece. |

| Processing cycle | 120 minutes. | 75 minutes. |

4.Economic comparison

When processing 100 gearboxes, ordinary milling requires 3 devices (lathe + milling machine + drilling machine), while compound processing can be completed by a single machine. JS company's measured data shows that compound processing reduces fixture costs by 45% and site occupancy by 60%. However, the purchase price of compound machine tools is 2-3 times higher than that of ordinary milling machines.

What are the key factors to consider when choosing CNC milling equipment?

1.Processing requirements analysis

Before choosing a CNC milling machine, you must clarify the processing requirements. You need to consider the hardness of the processing material, the size range of the parts, the processing accuracy requirements and the production batch. Soft metals such as aluminum alloys can use standard models, while difficult-to-process materials such as titanium alloys require equipment with higher rigidity. According to the American Society of Manufacturing Engineers (SME), about 35% of procurement errors are due to insufficient assessment of processing requirements.

2.Machine tool accuracy level

Machine tool accuracy directly affects product quality. Positioning accuracy should usually be within 0.01mm, and repeated positioning accuracy must be below 0.005mm. The CNC milling machine cost of high-precision machine tools is usually 40-60% higher than that of ordinary models, but it is a necessary investment for precision parts processing.

3.Control system performance

The control system is the core of the CNC milling machine. Mainstream systems such as Siemens and Fanuc provide different functional configurations. Newer control systems can achieve smoother interpolation motion and faster computing speeds, and high-quality control systems can improve processing efficiency by more than 25%.

4.Spindle performance

Spindle speed and power determine processing capabilities. Aluminum alloy processing usually requires a high-speed spindle of more than 10,000 rpm, while steel processing requires high torque. Spindle taper specifications (such as BT40, HSK63) also affect the selection of tool systems.

5.Table size and travel

Table size must be able to handle the largest part being machined. X/Y/Z axis travel must be more than 20% larger than the workpiece size to provide space for clamping. Any larger table will unnecessarily increase the cnc milling machine cost.

6.Automation configuration

The degree of automation affects the efficiency of production. Automatic tool change systems are able to reduce downtime, and automatic workpiece exchange systems are suitable for mass production. Automated devices, in the view of the German Machine Tool Manufacturers Association (VDW), have the potential to increase utilization by 30-50%.

7.After-sales service support

After-sales service is important. One should consider the supplier's technical support capability, response time and speed of spare parts supply for maintenance. Though quality service will increase the initial investment, it will reduce long-term operating risks significantly.

8.Energy consumption and maintenance costs

Apart from the purchase price of the equipment, long-term operating expenses must also be considered. High-efficiency models, although more expensive, may save 20-30% of electricity consumption. The expense of ongoing maintenance must also be included in the total expense.

Why is 5-axis CNC milling necessary for complex surface machining?

1.Reduce clamping error

The three-axis machine tool has to rotate and clamp multiple times to machine the curved surface, and the sum of error is over 0.1mm. The 5 axis CNC milling machine tool utilizes a rotary table to automatically locate the workpiece angle. When machining the turbine blade, the intake edge and exhaust edge are completed in one clamping, and the contour error is below 0.03mm. JS Company used this method to inspect helicopter rotors, and the product qualification rate was increased from 82% to 97%.

2.Optimization of tool contact

The incline angle of the tool has an effect on curved surface cutting quality. 5 axis machine tool inclines the tool axis to align with the surface normal, and the effective cutting area of ball-end milling cutter is enhanced by 40%. In processing artificial knee joints, the tool life is enhanced by 2 times, and surface roughness is up to Ra0.4μm.

3.Improve cutting efficiency

Five-axis link tool path is 60% shorter than three-axis. In manufacturing blades of aircraft engine, metal removal rate increases by 50%, and processing time is reduced to 9 hours from 18 hours. Our company uses DMG machine tool for manufacturing impellers of 800mm diameter, and blade thickness error is ≤0.05mm.

How to evaluate the cost-effectiveness of CNC milling service providers?

1.Verify technical ability and equipment level

Suppliers should possess 5 axis CNC milling equipment, with the ability to process complex surfaces and multi-angle feature parts. JS uses a 5-axis linkage machining center from Germany with ±0.005mm precision and a project qualification rate of over 95%. When dealing with an aircraft project, we utilized a 5-axis CNC milling solution to reduce the titanium alloy parts with originally required 3 clampings to single molding, saving 15% of processing time.

2.Analyze material adaptation

JS provides more than 50 material options, such as specialty materials of aviation aluminum and PEEK. JS supported medical device customers in completing production of composite structures of stainless steel and medical plastics, saving 20% of R&D costs with material performance testing.

3.Measure the cost structure of the entire process

There must be a comparison of quotation transparency and managing hidden costs. Our company uses an intelligent process planning system to reduce customers' manufacturing costs by 20% on average. One car parts project reduced raw material loss by 30% with a tolerance of ±0.01mm by optimizing tool paths and cutting parameters.

4.Authenticate the delivery cycle

An automobile parts manufacturer requires urgently 500 sets of aluminum alloy brake discs, and we complete the delivery within 3 days. The deviation of processed brake disc parts is below 0.01 mm, and loading test pass rate is 100%. This case well reflects our company's quick response and precision processing capacity.

5.Evaluate sustainable development capabilities

Select suppliers with green production processes. We reduce 15% of the volume of carbon emissions per unit product with recycling of waste and energy management processes. 5-axis CNC machining of aluminum alloy shell in a green energy project achieves 100% recycling of waste aluminum.

Summary

Being the basic technology of modern manufacturing industry, CNC milling technology can provide a complete range of solutions from simple plane processing to complex curved surface forming. In this article, various ways of processing such as plane milling, end milling, and composite milling are described in detail, and especially the advantages of 5 axis CNC milling in complex part processing are emphasized.

Whether they are precision components or complex structural components, selection of the appropriate milling process possesses tremendous potential for improving production efficiency and product quality. With rich industry experience and technical accumulation, JS can provide customers with whole-process services ranging from equipment selection to process optimization in order to help customers achieve optimal processing effects.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.What does 4-axis milling have more than 3-axis?

4-axis milling has one more rotary axis (usually A-axis) than 3-axis, allowing the workpiece to rotate around the X-axis. This design enables the machine tool to process the side or cylindrical surface of the part without re-clamping, which is suitable for processing complex structures such as gears and threads that require multi-angle cutting.

2.What tools are commonly used for CNC milling?

CNC milling commonly uses flat head milling cutters, ball head milling cutters, face milling cutters, T-slot cutters, drills and thread milling cutters. Carbide tools are suitable for steel parts, and coated tools improve aluminum processing efficiency.

3.How many axis devices are needed for surface milling?

Surface milling requires at least 3-axis equipment, but 5-axis CNC milling is required to process complex surfaces. 5-axis machine tools achieve multi-angle cutting through rotary axes (such as B-axis or C-axis), can complete multi-faceted processing at one time, reduce clamping errors and improve surface accuracy.

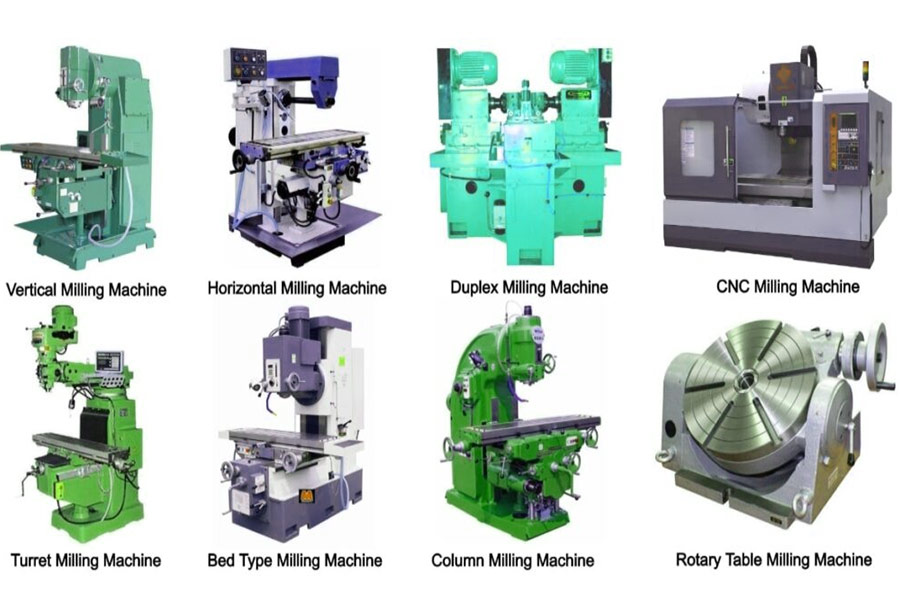

4.How many types of CNC milling machines are there?

CNC milling machines are mainly divided into four categories: vertical, horizontal, gantry and 5-axis. Vertical is the most common and suitable for small and medium-sized parts. Horizontal is suitable for long parts processing. Gantry is used for large workpieces. 5-axis can process complex curved surfaces.

Resources