Sheet metal fabrication is one of the core links in the research and development of mechanical structure, electronic equipment shell and industrial equipment. Its design process requires to consider many key factors, from raw materials to the adaptability of manufacturing process, from structural design optimization to surface treatment selection. Each link directly affects the quality and performance of the final product.

In this paper, the key problems to be considered in sheet metal parts design are analyzed in order to ensure the consistency and quality of each product and provide a completechain of reference from design to mass production.

What are the criteria for designing sheet metal parts?

1.The fracture modules

In sheet metal design, the breaking modulus directly affects the bending performance of sheet metal. When bending, the tensile strain on the outer surface is greater than that on the inner surface. A small radius can lead to cracking. This threshold is the minimum bending radius. In design, a minimum radius shall be determined according to the thickness of the material. If necessary, the ductility of the material can be improved by polishing and other processes.

2.Optimal design of metal holes and groove

Stamping process is an economical and efficient drilling method in metal sheets processing. The minimum size of the hole, slot or groove shall not be less than the thickness of the plate. This design principle can greatly improve production efficiency, reduce the risk of punch damage, and guarantee machining accuracy.

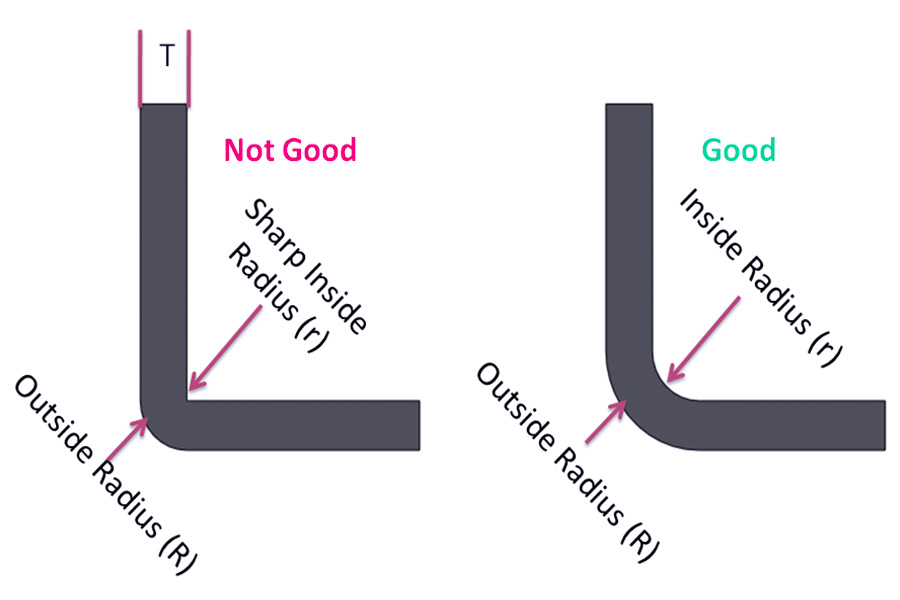

3.Minimum curvature radius

The minimum bending radius of sheet metal parts is mainly influenced by machining process and material properties. The more ductile the material is, the smaller the bending radius it can reach. In practical design, the performance differences of different metal grades must be taken fully into account. Modern DFM software can intelligently analyze these parameters to provide designers with practical and flexible solutions that meet industry standards.

4.Material selection and thickness matching

Prefer materials that are easy to process, such as aluminum sheet metal and galvanized sheet metal. Select thickness according to the process requirement of bending sheet metal. If it's too thin, it deforms, and if it's too thick, it bends and cracks. It is generally recommended to refer to a sheet metal gauge chart to ensure that the bending radius to thickness ratio is reasonable (e.g. 1.5 times the thickness).

5.Bend process selection

Depending on the complexity of the parts, such as for high-precision right-angle V-bending, suitable for bending the structure of the roll bending. JS precision manufacturing equipment supports precise bending of 0.5mm ultrathin plates. For multiple bends, it is necessary to plan the sequence of bends in advance, simplify the number and angle of bends, and avoid rebound or size deviation.

6.Optimize welding process

Welding is not the only option in sheet metal structural design. Many designers are used to soldering bracket schemes but ignore other, other potentially more optimized connection methods. We recommend that the following options be considered at the design stage:

- Integral cutting molding: Optimizing the cutting process of substrates to achieve structural function.

- Mechanical fasteners: Detachable connection scheme for bolts, rivets, etc.

- Sheet metal bending: The the material's own stiffness is used to construct the supporting structure.

What is the impact of material selection on sheet metal engineering?

In sheet metal engineering, material selection is not only a reflection of functional requirements, but also a decisive factor in manufacturing efficiency, cost control and final product quality. This can be better understood in the case of aluminum sheet metal and steel.

1.Processing difficulty and process adaptability

Aluminum sheet metal are more malleable than steel, have a smaller bending radius (usually 1-2 times the thickness of the material), are easier to form and are less prone to cracking during bending and stamping. For example, the application of aluminum plates in aviation components depends on their lightweight characteristics, while steel is better suited to heavy mechanical load-bearing structures because of its high strength.

2.Cost effectiveness

If we focus on strength, steel may be the preferred option, but its high density and weight lead to increased transportation and installation costs. On the contrary, although the unit price of aluminum plates is higher, overall, the energy consumption of aluminum plate can be reduced, processing efficiency can be improved, in the long run, can improve the value for money of aluminum plate.

3.The General Assembly Environmental Adaptation

Galvanized sheet metal improves its corrosion resistance by coating, making it suitable for humid environment. However, special care should be taken to protect the integrity of the coating during processing. Aluminum plates have natural antioxidant properties that reduce late maintenance costs.

4.The Sustainability trend

Aluminium is high as 95% recyclability rate, in line with green manufacturing trends, while steel is relatively carbon emission intensity. Many companies are turning to aluminum components,such as new energy battery trays, to achieve carbon neutrality goals, which is also driving the shift in sheet metal processes to low carbon.

What factors should be considered when designing sheet metal parts?

Sheet metal design is often caught in a vicious cycle of design and rework. Data shows that 30-50% of the product development cycle is spent on repeated revisions and that nearly a quarter of engineering errors were due to inadequate design processes. In fact, there is a huge disconnect between CAD design and reality.

When designing sheet metal parts, the process characteristics of sheet metal bend must be closely combined with manufacturing feasibility:

1.The use of standardized moulds

Preferably use standard mold dimensions for bending to avoid customizing expensive molds. If the component structure is complex, it can be formed by welding or riveting a combination of standard molds.

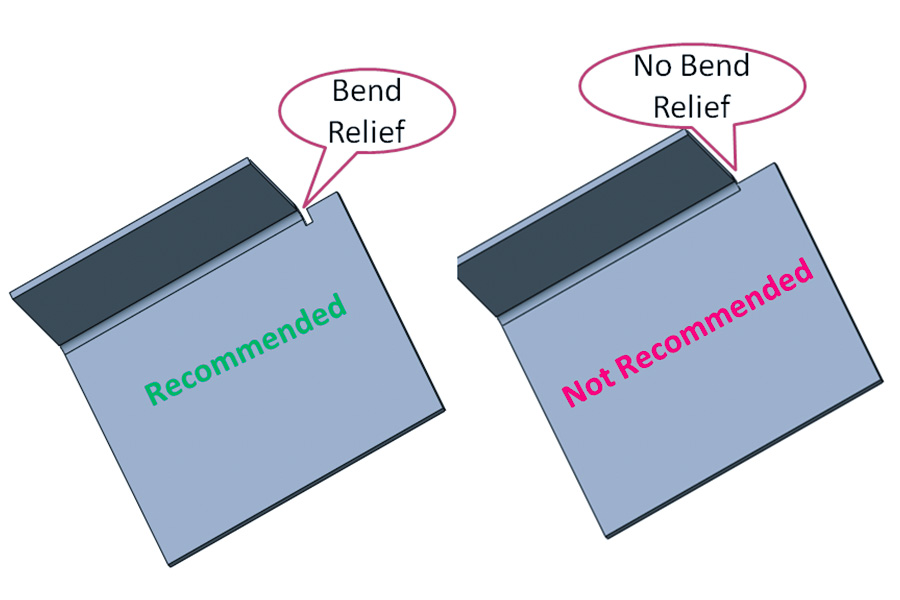

2.The bend distance and avoid hole position

Holes, incisions or connectors should be kept at least 4 times the thickness of the material (i.e. 4T principle) away from the curved edges to prevent deformation caused by bending and stretching. When bending aluminum plates, special attention should be paid to ductility differences in order to avoid tearing at the hole position.

3.Avoid closed geometry

The linear stamping principle of plate bending restricts the formation of closed structure. In design, openings must be retained or used for segmented bending, and fully enclosed boxes replaced with U-shaped grooves.

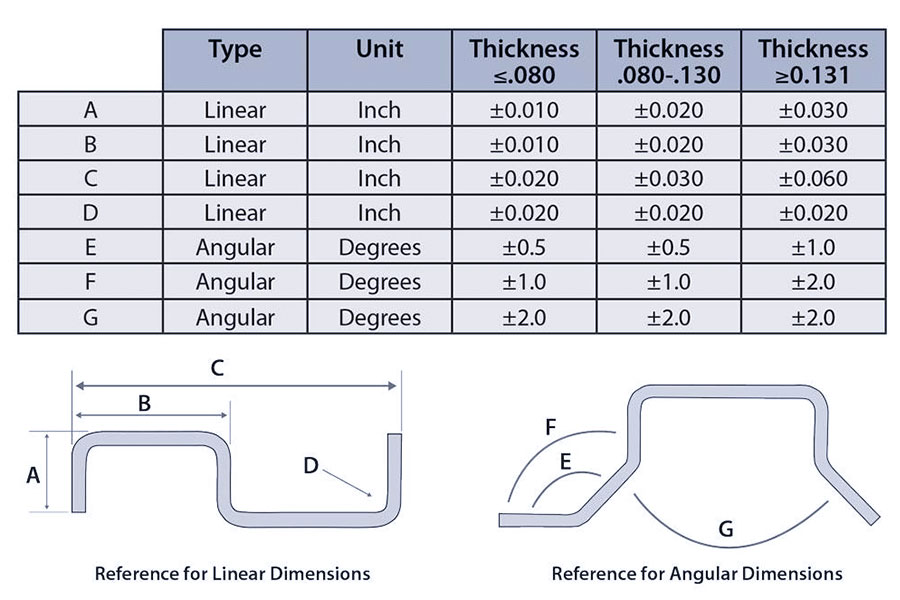

4.Tolerance control

Sheet metal tolerance is generally ±0.1mm to 0.5mm, compared to CNC machining, the accuracy requirements are not high. The final tolerance needs to be determined according to the thickness of the material, the number of bends and the accuracy of the equipment. Thin plate will accumulate errors after multiple bends and compensation space is needed.

5.Use an even bending radius

Standardized bending radius,such as 0.030 inches, can reduce mold switching time. The recommended bending radius for aluminum sheet metal is 1-1.5 times thicker, while steel requires a larger bending radius to avoid rebounding.

6.Alternative welding options

It is easy for thin plate to be deformed by welding. Riveting and pressure riveting can be chosen as alternative connection. When installing PEM hardware, it is necessary to match the thickness of the material to avoid cracking caused by stress concentration.

How to avoid common errors in sheet metal design?

1.Material selection intensity

- Many engineers misuse high-strength materials, such as 6061-T6 aluminum, causing bending and cracking. For example, one company chose 6061 aluminum for strength, but cracks appeared in bending process, while 5052-H32 aluminum was fully adapted because of its better ductility.

- Material Solutions: JS prioritises bend sheet metal friendly materials (such as 1060 pure aluminum, SPCC cold-rolled steel) whose tensile strength and ductility compatible with bending processes. At the same time, we provide a database of materials to avoid the use of special alloys that require custom molds.

Often, the bending radius is not retained or the bending sequence is confused, which leads to part deformation. In the design of the containment box, rework was required due to the inability to achieve containment bending (additional process ports are required).

JS solution:

- We set a standardized bending radius (e.g. 1-1.5 times the thickness of the material) against the industry standard of 0.030 inches.

- Plan to bend sheet metal in sequence, first folding the secondary edges, then dealing with the main structure and marking a clear bending direction (V-shaped or roll bending).

3.Sheet metal processing Tolerance design

The tolerance design of sheet metal parts adopts ± 0.05mm CNC machining accuracy standard directly, which basically confuses the physical characteristics of these two machining processes:

- CNC machining eliminates the elastic deformation of materials by cutting, and sheet metal bending is a plastic deformation process, material rebound is inevitable. SPCC cold-rolled steel, 90 example, can rebound amount between 0.2 and 0.3mm (1mm thick) when bent at 90°. If numerical control tolerance control is used, the actual angle error will far exceed the functional allowable range.

- Cumulative errors of multiple bending (e.g. the sum of the errors after 3 bends is greater than +/-0.15 mm) do not exist in CNC single processing, but in sheet metal process, the angle and size deviations will increase gradually due to different bending sequence, mold clearance and material flow characteristics. This process difference leads directly to systemic risks such as assembly interference and hole cracking.

Solutions:

- If it becomes apparent during processing that the markup tolerance cannot be achieved, our engineering team will consult with you as soon as possible to design the design optimization solutions. A better approach would be to maintain close communication with our experts during the design phase.

- Special reminder to projects that have been organically working on matching parts: Once a plate part is complete, it can be difficult to modify it. Our team strongly recommends a sheet metal priority strategy, where sheet metal manufacturers complete design reviews before processing.

4.Holes design

The design of hole position of sheet metal parts directly influences production and product performance. Common misconceptions include relying too much on special aperture of unmarked tools, or positioning holes too close to edges and curved lines, leading to deformation and assembly problems.

Solutions:

- Drill bit specifications suitable for different aperture sizes:

| Bore diameter | Applicable drill specifications | Scene | Cost effectiveness |

| φ0.125 (3.2mm) | Standard # 40 drill bit | Installation holes, ventilation holes | Tool costs ↓ 40% |

| φ0.25 (6.35mm) | Standard # 8 drill bit | connection holes for structural components | Processing efficiency ↑ 25% |

| φ0.5 (12.7mm) | Standard # 20 drill bit | Flange edge fixing hole | Mold lifespan extended by 50% |

- The safe limits of holes:

| Feature type | Minimum distance requirements | Failure case |

| Adjacent distance of the curved line | Thickness≥ 2 times(e.g. 1mm board → ≥2mm) | hole length bend line 1.5mm → Tear |

| Edge of hole | Thickness≥ 1 times (e.g. 0.8mm board→ ≥0.8mm) | hole margin 0.5 mm → edge crack |

| Hole spacing | Thickness ≥3 times (to prevent stress superposition) | hole spacing is twice as thick → spacing deformation the plate |

5.Surface treatment: feasibility and cost considerations

Enterprises require special surface-treatment processes that cause costs to soar or processes to become unviable. Recently, a JS customer asked for nickel foil for copper parts, but only a handful of factories in the world have the capability and nickel foil is too expensive.

Solutions:

- We would advise customers to prioritise common processes such as spray coating and anodizing and to confirm feasibility with them in advance.

- If custom surface treatment is required, additional construction period (e.g. 8 weeks of special paint delivery time) is required.

How to choose the optimal thickness for metal welding?

1.Matching material type and thickness

- Stainless steel: According to the sheet metal gauge, welding thickness is generally 0.5-6mm for low carbon steel and 1-4mm for stainless steel (e.g. 304). For example, TIG welding is suitable for 0.5-3mm sheets and MIG welding is suitable for 3-6mm sheets.

- Aluminium and aluminum alloys: Aluminum plates has high ductility, but easy to oxidize, welding thickness should refer to sheet metal gauge chart. TIG welding is recommended at 0.3-2mm and MIG welding is recommended at 1-5mm. If more than 5mm, preheat or other processes should be used.

2.Welding process selection guide

- For thin stainless or aluminum plates less than 1 mm, TIG welding is our recommended technique. The TIG weld can weld rigidly without bending the plate.

- MIG welding is better used when welding with medium-thick plates. The welding speed of it is comparable to relatively high, but watch out when you adjust the current, or you will weld through the plate very easily. Our factory masters have an experience that the welding gun moving speed must be appropriately matched to the current.

3.Choose materials based on usage scenario

When we need to create load-bearing items such as brackets and frames, engineers usually like to use more than 3mm thick steel. With such a thickness, the tensile strength will be sufficient, and the product will be stronger. Just as we make a house using strong steel bars, these thick steels can sustain the entire building over time.

4.Process constraints that need to be taken into account in design

- There are basic requirements on material thickness for all welding processes.

- When laser welding of stainless steel, plate with at least 0.5 mm thickness must be used. Otherwise, it will not be welded strongly.

- When handling steel plates over 6 mm thick, workers will groove the edge of the steel plate first. The groove shapes are generally V-shaped and U-shaped, like creating a special channel for welding. The advantage is that the solder can fully penetrate and firmly bond the two steel plates together.

5.Cost control measures and efficiency enhancement

- Too thin plates will be troublesome: The application of plates too thin, i.e., below 0.5 mm, is likely to weld through or warp. This will require frequent maintenance, which will be a cost addition.

- It doesn't suit plates too thick as well: Plates over 8 mm thick must be welded several times, which consumes time and material. Here, profiles or castings are preferably used.

- The best option: It's recommended to look up the standard sheet metal gauge chart and choose common thicknesses such as 1 mm, 2 mm, and 3 mm. This can reduce special processing.

How to mass produce complex sheet metal parts through JS automation equipment?

1. Intelligent design and simulation optimization

JS team allows customers to upload CAD files in any format. We use simulation software automatically and predict the forming effect of sheet metal parts in advance. For complex structures, our team achieves layout optimization through parametric design in order to reduce material waste and achieve the compliance of high precision requirements of ±0.005mm. This step can reduce the design cycle by 30%, especially for sheet metal fabricators projects which contain many iterations.

2.High-speed automated processing center

JS employs a fully automatic production line of multi-axis laser cutting machines, CNC punching machines and bending machines. For complex sheet metal parts:

- Laser cutting: Cutting accuracy of ±0.02mm, with more than 50 materials applicable such as stainless steel and aluminum alloy, and cutting speed is

- 3 times higher than that of traditional equipment.

- Stamping: With servo presses for repeated positioning at the micron level to handle complex punching and stretching processes.

- Bending automation: Through machine clamping and visual positioning systems, multi-angle precision bending is achieved to reduce errors of manual intervention.

3.Real-time quality monitoring

Our production line can scan sheet metal dimensions and surface defects in real time, with a 99.8% pass rate. We also provide SPC statistical process control reports to optimize process parameters and reduce defect rates through big data analysis. One car customer, for example, cut rework costs by 40% through JS's automated quality inspection system.

4.Fast delivery

JS's intelligent scheduling system supports small batches and multiple varieties of hybrid production and can complete the entire process from design to delivery in 7 working days.

Summary

Each step of sheet metal fabrication is essentially a process of dialogue with metal. From design drawings to workshop production, smart technology is like giving engineers perspective eyes that can not only see the tempering of plates of different thickness through stamping process, but also use digital models to pre-verify millions of corners.

Now our production lines are not just mechanical repetitions, they are more like bridges between metal and data. Each CNC punch landing proved the craftsmanship of structural design. Our engineers have a high level of expertise to assist businesses complete difficult sheet metal fabrication projects.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.How to prevent deformation of intricate structures?

When metal machining, the shape of cutting must be designed to minimize deformation, bend slowly, and manage temperature. The machine employs hard die and leveling machinery to automatically adjust bounce and maintain shape.

2.How to improve sheet metal parts strength?

Select high strength material, enhance reinforcement design, apply rounded corner bending, laser cutting, minimize burr, control welding, minimize deformation.

3.What is minimum bending radius?

Minimum bend radius is usually 1-2 times of material thickness. Aluminum plates to be used single time and steel more than 1.5 times to avoid cracking.

4.How to achieve sheet metal parts flatness?

In order to have best structural design, use proper material, bending process, work with high rigidity die and leveling process, reduce rebound deformation.