In modern manufacturing, rapid prototyping, as the core bridge between digital design and physical La fabrication est allée bien au-delà du prototypage traditionnel.

Quels matériaux peuvent être utilisés pour le prototypage rapide?

1. Engineering Plastics

combinant la résistance, la ténacité et les avantages des coûts, le matériau convient à Rapid Verrification des structures mécaniques . Pour l'exemple:

2. Matériaux métalliques Les prototypes de haute précision sont réalisés par l'usinage CNC ou Empression en métal 3D pour répondre aux besoins élevés de résistance :

3. résine photosensible La résine liquide est formée par photopolymérisation et a une précision de surface élevée: 4. Composites Materials combinant des matériaux de fibres et de matrice pour surmonter les limitations de performances d'un seul matériau: 5. Biomatériaux 6. Matériaux dégradables Nouvelles options pilotées par les exigences environnementales: Dans le domaine du prototypage rapide, les méthodes communes peuvent être classées dans les catégories suivantes, chacune peut être efficacement itérée et validée par : 1. Data-TranslateID = "06C09D032DE5C71CAD9BA3A8E42208E3" Data-Pos = "3" Data-Len = "36" DATA-V-7B79C893 = ""> Voici une comparaison des différences de base entre le prototypage rapide et l'usinage CNC: 1. Degré de normalisation des documents de conception La précision du modèle prototype dépend principalement de la précision des données d'entrée. 2. Caractéristiques du matériau et adaptabilité de sélection Les propriétés physiques de différents matériaux ont une grande influence sur la précision de l'usinage. 3. Processus de fabrication et précision de l'équipement 4.Level of control of reprocessing technologies After the prototype model is completed, it needs to be polished and electroplated. JS company ensures that these processes do not introduce additional errors through rigorous quality control systems such as three dimensional inspections and surface roughness testing. 1.Biocompatibility and safety PEEK is ISO 10993 cytotoxicity testing and FDA certified, and its prototyped model can be used directly for human implant validation to avoid the risk of immune rejection. 2.Matching mechanical properties to human needs In orthopedic prototyping, PEEK (3.6 GPa) has an elastic modulus close to human bone (1-20 GPa) that reduces stress shielding and prolongs the life of the implant. 3.High temperature and chemical resistance Prototyped of surgical instruments require repeated high-temperature sterilization (such as autoclaving at 134 °C), where PEEK maintains a stable size and is resistant to corrosion by disinfectants such as alcohol and hydrogen peroxide. 4.Capacity to implement complex structures Using 3D printing, PEEK can be used to manufacture prototyped structures such as porous bone scaffolds, promote bone cell growth and reduce material usage to achieve lightness. 5.Balancing cost and efficiency Compared to titanium alloys, PEEK reduces processing costs by 30%-50%, shortens shortens prototyping cycles by 40%, and makes suitable for the development of small-scale custom medical devices. 1.Extreme environmental adaptation 2.Excellent mechanical performance High intensity/lightweight: The structure of the missile body requires the use of carbon-fibre-reinforced composites (five times the specific strength of steel), such as the J-20 fuselage components. Shock and fatigue resistance: The cartridge is made of tungsten alloy (density (density 19.3g/cm³) to withstand the blast, and aircraft landing was made of ultra-high strength steel (tensile strength ≥1500 MPa). Creep-resistance and abrasion resistance: Tank tracks were coated with high manganese steel (working hardness index ≥0.3) and missile rails were coated with tungsten carbide (friction coefficient ≤0.1). 3.Security, confidentiality and counter-surveillance Electromagnetic shielding: The stealth fighter jets coating inhibits radar radar detection ferrite absorbing materials (reflection loss ≥20 dB). Non traceable characteristics: Special alloys add rare earth elements,such as gadolinium and dysprosium, to remove material fingerprints by microstructure blurring. Counterfeiting label: The cartridge uses laser microengraving QR code embedded with nanomagnetic particles for full lifecycle tracking. Environmentally friendly biodegradable prototype material About Key Technologies and Applications 1.PLA Rapid prototyping: 2.Adapting public PHA to medical conditions: 3.Limitations of natural fiber reinforcement Hygroscopicity: Bamboo fiber can absorb up to 15% of water in high humidity environments and require surface modification to accommodate precision rapid prototyping components. 4.Compost degradation conditions Industrial composting standards: Degradation is required at temperatures of 58 degrees Celsius and humidity over 80%. household composting is only 30-50% more efficient than industrial conditions. Reasons related to substance 1.Excessive shrinkage: After cooling, the volume of the material shrinks by more than 0.5mm, resulting in prototype deformation and hole displacement, especially affecting the precision of precision components. 2.Excessive moisture absorption: Materials such as PLA and nylon easily absorb moisture from the air, resulting in a 30% reduction in strength, resulting in flaking or surface cracks between layers and undermining the structural integrity of rapid prototyping parts. 3.Poor material compatibility: When the photosensitive resin does not match the printing equipment, problems such as clogging and wire breakage are likely to occur, leading to interruption of printing or deterioration of surface quality. 4.Differences in thermal expansion coefficient: High thermal expansion coefficient of metallic materials in the course of high temperature processing, will occur deformation, leading to precision components blockage or size tolerance, increasing the cost of later correction. 5.Material performance mismatch: If the selected prototype material is not strong enough or high brittleness, it may fracture during the test and design function cannot be verified. Process parameter setting error JS has taken relevant measures in this regard: 1.Accurate machining technology: Advanced CNC machine tools are used to achieve ±0.005mm of ultra-precision tolerance control, ensuring that every component strictly complies with design specifications. 2.Materials Science Management: Provides more than 50 metals, plastics and composites and optimizes processes based on material material properties (e.g. thermal expansion coefficient) to reduce deformation during processing. 3.Digital quality control: Through CAD document pre-review and 3D inspection equipment, to monitor the product size accuracy throughout the process, and timely correct possible deviations. 4.Environmental and process standardization: Maintain stable workshop humidity, implement uniform process parameters, and reduce the influence of environmental factors on material stability. 5.Experience-driven process optimization: A team of engineers with 20 years of experience, more than 30 technical training sessions per year, continuous improvement of process solutions, and increased consistency in repeat production. In the field of rapid prototyping, the boundary of material selection is constantly being reshaped, which drives the evolution of prototyping model from simple form verification to functional and intelligent. From its early reliance on a single engineering plastic to now covering metals, ceramics, biobased materials materials and smart composites, 3D printing has given prototypes properties closer to the end product through material innovation. With continuous breakthroughs in materials science, future prototype models will overcome traditional performance limitations, achieve more complex structural validation and functional testing in aerospace, consumer electronics, and bioengineering, and further cement the status of rapid prototyping technology as a core tool for product development. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.Can rapid prototyping materials be reused? Some plastics,such as PLA, can be recycled, but their performance deteriorates. metal powders can be reused, while photosensitive resins are often not. 2.Will rapid prototyping materials be affected by temperature? Yes, temperature has a big impact on material properties. ABS, for example, deforms at high temperatures, PLA becomes brittle at low temperatures, nylon loses strength when it moisture absorption, and photosensitive resin soften at high temperatures. In order to avoid warping and cracking, the temperature difference between printing and reprocessing needs to be controlled. 3.Does multi-color printing require switching materials or technology? Multi color printing can be achieved by converting materials (such as multicolor lines) or technologies (such as multi nozzle FDM). The former requires manual replacement of materials, while the latter automatically blends colors to reduce manual intervention. 4.What are the characteristics of nylon material in rapid prototyping? Nylon material is wearable, flexible and lightweight. It is suitable for dynamic situations such as gears and moving parts. However, it deforms easily when it absorbs moisture and requires control of ambient humidity. JS Expert en prototypage rapide et fabrication rapide Spécialiser dans l'usinage CNC, l'impression 3D, la coulée d'uréthane, l'outillage rapide, le moulage par injection, la coulée de métal, la tôle et l'extrusion. Étiqueter:

Quelles méthodes sont utilisées dans le prototypage rapide?

Méthode d'application

principe de travail

caractéristique

FDM (Modélisation des dépôts fusionnés)

La fonte chaude est extrudée et empilée.

faible coût, facile à utiliser, adapté à l'ABS, à l'APL et à d'autres plastiques.

SLA (stéréolithographie légère)

La résine liquide de durcissement UV est superposée.

Surface lisse et haute précision (± 0,1 mm) pour les structures complexes.

SLS (frittage laser sélectif)

frittage au laser des matériaux de poudre (nylon, poudre métallique).

Aucune structure de support, haute résistance, adaptée aux tests fonctionnels.

DLP (traitement de la lumière numérique)

Résine de durcissement en couches de projecteur numérique.

La vitesse de moulure est rapide et la précision est comparable à SLA.

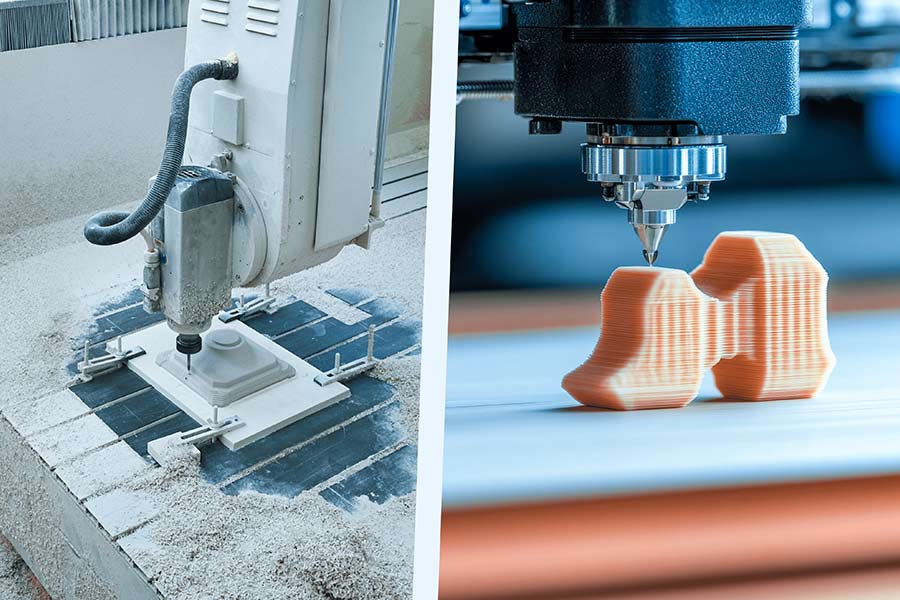

Quelle est la différence entre le prototypage rapide et l'usinage CNC?

Comparaison des dimensions

Prototypage rapide

CNC Machining

Principes de fabrication

Sur la base de la fabrication en couches (par exemple SLA, SLS, etc.), les matériaux sont empilés et moulés.

Sur la base de coupe soustractive, utilisez des outils de coupe pour éliminer l'excès de matières premières.

Applicabilité du matériau

Soutenez plusieurs matériaux (plastiques, résine photosensible, poudre métallique, etc.) pour les prototypes rapides.

Le grand nombre sont les métaux (aluminium, acier) et les plastiques durs (ABS, PC).

Précision et qualité de surface

Précision ± 0,1-0,5 mm, surface poreuse / rugueuse, post-traitement requis.

La précision est à moins de ± 0,02 mm, la douceur de surface élevée et peut être utilisée directement pour les tests fonctionnels.

rentable

Faible coût de la production de petits lots (pas de frais de moisissure), adapté à une itération rapide.

Le coût unitaire est relativement élevé et adapté à la production de lots moyens.

Scénarios d'application

Validation du concept précoce (par exemple les prototypes de voitures), prototypes structurels complexes (par exemple, grilles creuses).

Tests fonctionnels (tels que les cadres téléphoniques) et la préparation de la production de masse de composants de précision.

Quels facteurs affectent la précision des modèles de prototypage?

Why choose PEEK material for medical equipment?

What are the special requirements for prototype materials in the military industry?

Performance requirements

Specific scenarios

Matériaux typiques

Heat resistance (800 °C+)

Missile engine nozzle, spacecraft thermal protection layer.

Titanium alloy and ceramic matrix composites. (CMC).

Low temperature resistance (-196 °C)

Polar equipment, liquid hydrogen fuel storage tanks.

Aluminum alloy (7075-T73), PEEK.

Radiation resistance

Nuclear submarines, space probes.

Molybdenum alloy, polyethylene (HDPE).

Corrosion resistance (salt spray/acid alkali)

Ship propeller, mine-resistant hull.

Stainless steel 316L, titanium Ti-6 Al-4V.

What are the environmentally friendly biodegradable prototype materials?

Type of material

Typical material

Core features

Suitable for rapid prototyping technology

Biobased plastics

PLA (Polylactic Acid)

Complete synthesis (180 days), non-toxic and easy to process (FDM printing temperature 190-220 °C).

FDM, SLA.

PHA (polyhydroxyalkanoates)

The ocean is biodegradable, heat-resistant (melting point 180 °C) and extremely biocompatible.

SLS, injection molding.

Natural fibre boost

Bamboo fiber boost PLA

Compared to pure PLA, it is 50% stronger, a renewable resource, and has a manageable degradation rate (adjusted for starch addition).

CNC machining, 3D printing.

Hemp fiber boosts PBAT

High toughness 80% increase impact resistance), acid-base resistance, suitable for complex structures.

Compression molding and lamination process.

Synthetic biodegradable materials

PBAT (Polyadipic Acid/Butanediol Terephthalate)

The compost degradation cycle ≤ 90 days, mixed with PLA, can improve mechanical properties.

Blow molding, thermoforming.

PBS (polybutylene succinate)

High temperature resistance (melting point 110 °C), excellent creep resistance, suitable for load-bearing members.

Injection molding, extrusion molding.

What are the common reasons for rapid prototyping failures?

Classification of reasons

Concrete manifestations

Influencing results

Improper layer thickness

Excessive layer thickness (>0.2mm).

Surface roughness excess (Ra >6.3μm).

Temperature parameter errors

Low Printing temperature (if PLA is below 190°C).

The material cannot be bonded and the bond between layers is insufficient.

Lack of support structures

Suspension structure without added support.

Lower cave-in, inner void.

Scanning too fast

SLA laser scan speed>8m/s.

Decreased molding accuracy (±0.1mm error).

How does JS company ensure the stability of prototype size?

Résumé

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com FAQS

Resources

Blogs connexes

Pourquoi les grandes entreprises s'appuient-elles sur un prototypage rapide? Révéler les principales considérations de conception

Du concept à la réalité: 5 applications inattendues de la technologie de prototypage rapide

Guide de 5 minutes pour 6 techniques de prototypage rapide principales: l'impression 3D n'est-elle pas vraiment la meilleure option?

Économisez du temps et de l'argent? Guide du matériau de prototypage rapide: éviter 90% des erreurs courantes

Prototypage rapide 5 étapes de base: Guide du débutant pour maîtriser le processus en 2025

Qu'est-ce que le prototypage rapide?

Criticism

Featured Blogs