Tecnología de impresión de jet de tinta , la tecnología de impresión 3D supera las limitaciones de los procesos tradicionales, logra estructuras complejas y desarrollo rápido de prototipos, proporcionando soluciones innovadoras para una producción personalizada y escalable.

> ¿Cuál es la definición básica de impresión 3D?

3d imprimir (fabricación adicional) es una tecnología de mezcolación digital que la fabricación de la molecanza digital This technology has broken through the physical limitation of traditional cutting procesar y realizar la combinación orgánica de morfología y función biomimética.

Técnicamente, 3DPrinting se basa en procesos como FDM, SLA o SLS, lo que hace posibles estructuras compuestas multimateriales. This dual innovation in technology and services has made 3D printing an interface between digital twin and the physical world, redefining the boundaries of scale y personalización.

¿Cómo se está desarrollando el mercado global de impresión 3D?

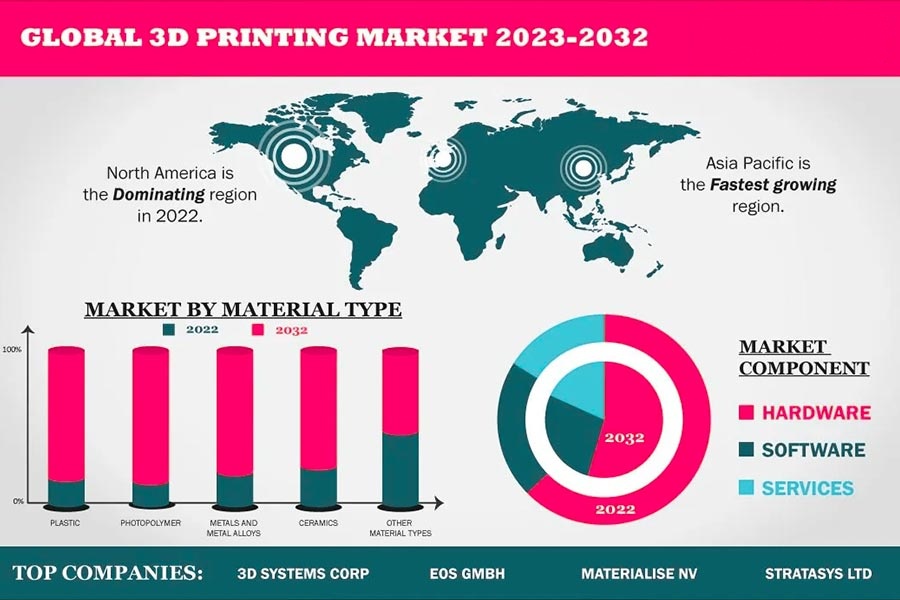

1. tendencia global de escala y crecimiento

de acuerdo con el 2023 Los modelos de impresión 3D representan más del 35% de los requisitos de diseño y fabricación, incluido el desarrollo de prototipos industriales, implantes médicos y productos de consumo. Producción conducida y personalización a pequeña escala . Se espera que el tamaño general del mercado fuera de USD 50 billones a una tasa de crecimiento anual compuesto compuesto por el 15. 2027.

2. Datos de tamaño de mercado de impresión 3D global (2022-2027)

| año | tamaño del mercado (en miles de millones de dólares estadounidenses) | tasa de crecimiento anual (CAGR) | áreas de crecimiento central | factores de conducción clave |

| 2022 | 240 | 15.3% | aeroespacial, médico, automotriz. | La demanda de modelos de impresión 3D de metal ha explotado. |

| 2023 | 276 | 15.3% | Impresión de metal, modelos dentales. | Promoción de los servicios de impresión. |

| 2025 | 375 | 16% | Manufactura inteligente, modelos de construcción. | avances en modelos de impresión 3D multimaterial. |

| 2027 | 500 | 15.3% | Bioimpresiones y productos de consumo personalizados. | Expansión del servicio de impresión en la nube. |

3. mercados segmentados y distribución regional

<

impresión 3D metal (35%):

- Áreas centrales: aeroespacial (que representa más del 65% del mercado de impresión de metales), las boquillas de combustible del motor de aviación (25% de reducción de peso, 5 aumento en la vida), Barreras técnicas: los avances tecnológicos como la sinterización colaborativa de múltiples láser (por ejemplo, EOS M400) y la fusión de haz de electrones (EBM) tienen una producción de topológica a gran escala a gran escala de estructuras de topología compleja, pero los costos de equipos (sobre $ 2 millones de $ 2 millones/pie Entrada.

Polymer 3D Impresión (40%):

- Electrónica de consumo: la tecnología Polyjet puede producir estructuras impermeables para teléfonos móvil

- Personalización médica: Admite la producción en masa invisible modelos personalizados ortodónticos con una capacidad de producción diaria de más de 500 unidades.

- Prototipos rápidos: los ciclos de diseño industrial se pueden comprimir en un 70% utilizando herramientas de diseño paramétricos, y los prototipos se pueden entregar dentro de las 48 horas.

- Personalización médica: Admite la producción en masa invisible modelos personalizados ortodónticos con una capacidad de producción diaria de más de 500 unidades.

por región regional mercado:

| área | tamaño del mercado en 2022 (en miles de millones de dólares estadounidenses) | los principales controladores de crecimiento | América del Norte | 90 | fabricación aeroespacial y automotriz. | Europa | 75 | Implantes médicos, modelos de construcción. | Asia-Pacific | 60 | productos electrónicos, personalización dental. | otras regiones | 15 | Educación y productos culturales y creativos. |

4. controladores de crecimiento futuros

- iteración tecnológica: multi material 3D Modelos de impresión Impulsar la producción masiva de componentes funcionales complejos, tales tales tales tissues.

- actualización del modo de servicio: los servicios de impresión 3D integran herramientas de diseño de IA para automatizar el proceso desde el modelo hasta los productos terminados.

- Soporte de políticas: Occidental Industry 4.0 planea estimular aún más la demanda mediante la integración de la impresión 3D en las estrategias de actualización de fabricación.

> ¿Cuáles son los desafíos y limitaciones de la impresión 3D?

1. limitaciones del material

Cuando el rango de materiales disponibles para el modelo de impresión 3D es limitado, especialmente en campos de alto rendimiento. impresión 3D de metales de grado industrial requiere una pureza de polvo extremadamente alta, mientras que los materiales de resina convencionales tienen dificultades para cumplir con los requisitos de durabilidad a largo plazo, que limita directamente la aplicación del modelo de impresión 3D en el aeroespacio, el implante y otros escenarios y otros escenarios.

Accouts y problemas de calidad A pesar de los avances en la tecnología, la precisión del modelo de impresión 3D todavía está influenciada por la resolución del dispositivo y el espesor de la capa. this opes a 3. Limitaciones de diseño de estructuras complejas 3D imprenta las excelaciones creando complejas geometric shapes ">"> ">" El diseño medio puede ser bueno, admite el diseño medio, lo que puede dar un acuerdo, el admitir el diseño central está bien, lo que puede llevar el diseño medio, ">"> ">"> " deformación o defectos de la superficie. 5. falta de estandarización y certificación Highly dependent on reprocessing La mayoría del modelo de impresión 3D requiere una molienda, pulido o tratamiento térmico para cumplir con los requisitos finales de rendimiento. Environmental and sustainability challenges 3D La impresión es difícil de reciclar y algunos materiales de resina. Corriente 3D 3D 3D 3D 3D Los modelos 3d 3D son tradicionales que son tradicionales que son tradicionales que son tradicionales que son tradicionales que los modernos tradicionales son tradicionales que los modernos tradicionales que son tradicionales que son tradicionales que son tradicionales que son tradicionales que son tradicionales que son tradicionales. fabricar y requerir innovación tecnológica para reducir los desechos de recursos.

¿Cómo se usa la impresión 3D para la creación de prototipos?

1. iteración rápida y validación de diseño

- La impresión 3D puede transformar rápidamente los diseños CAD en prototipos físicos, acortando el ciclo del concepto al objeto físico.

- Asociación de tecnología JS: admite cargar formatos de archivo 3D como step y stl y promete cotizaciones dentro de las 24 horas . itsuttype-up. At the same time, 98% of orders can be entregado a tiempo, asegurando una transición perfecta de la producción prototipo a las etapas de desarrollo posteriores.

Las técnicas de impresión 3D como SLA y SLS alcanzan la precisión de ± 0.005 mm y son adecuadas para la verificación prototipo de estructuras complejas o componentes de precisión.

5.Formation of complex complex structures 6.Green manufacturing practices 1.Medical and Biotechnology Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc. JS technology association: 2.Automotive and Aerospace Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades). JS technology association: 3.Education and research Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development. JS technology association: 4.Industrial manufacturing Application scenarios: Mold inserts, fixtures, automation equipment components. JS technology association: Real-time application analysis of JS Consumer electronics industry: Cooling components for smart wearables Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces. Technical difficulties: JS company solution: 1.Process selection 2.Design optimization 3.Quality control 4.Technical highlights 5.Achievements 1.Material innovation New high-performance metal alloys: Breakthroughs in biocompatible materials: Expansion of Composites Applications: 2.Technological breakthroughs 3.Extension of application In the medical field: Aerospace: 4.Sustainable technology 5.Frontier exploration 1.Automated process upgrades 2.Intelligent scheduling and resource management 3.Innovations in materials and processes 4.Standardization and lean production 5.Energy and equipment maintenance management The application of 3D printing technology has pushed the boundaries of traditional manufacturing, from lightweight smart wearable devices in the consumer electronics industry to precision parts maintenance and complex structural innovations in industrial equipment. Not only does the technology shorten product development and reduce customization costs, it also provides unprecedented solutions for the industry through the diversity of materials and process flexibility. A pioneer in 3D printing technology, JS is driving the transition 3D models printing from prototype validation to mass manufacturing with its high precision processing capability (e.g. ±0.005mm tolerance), multi-material compatibility and intelligent manufacturing processes. Whether personalized prosthetics in the medical field or abrasion-resistant coating repairs for industrial devices, 3D models printing is redefining manufacturing possibilities. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.How to use 3D printing to customize prosthetics in the medical field? Through medical scanning modeling, biomaterial 3D printing and other methods, personalized prosthetics are designed to meet patients' needs accurately. 2.Can 3D printing produce complex mechanical parts? By using SLM and other technologies, complex metal parts such as aircraft engine blades and automobile transmission components can be manufactured directly, breaking through the limitation of traditional technology. 3.What parts can be 3D printing for cars? Cars can be 3D printed with lightweight components such as brackets and gears, interior parts, prototypes and tool fixtures to improve design freedom and productivity. 4.How can 3D printing help with school teaching? 3D printing supports students to build hands-on models, visualize abstract concepts, improve practical skills, and think creatively.

What industries are currently covered by 3D printing technology?

What are the latest developments in 3D printing technology?

How can JS achieve a 15% efficiency improvement in 3D printing?

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment preparation time (single order)

8 minutes

20 minutes

+60%

Post processing time (per piece)

12 minutes

30 minutes

+58%

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment utilization rate

82%

65%

+26%

Order delivery cycle

4.5 days

5.5 days

+18%

Indicator

JS scheme

Other printing shops

Efficiency improvement

Material switching time (single order)

3 minutes

15 minutes

+80%

Single layer printing time (SLA)

3 seconds

6 seconds

+100%

Indicator

JS scheme

Other printing shops

Efficiency improvement

Clamping time (single order)

5 minutes

15 minutes

+67%

Novice training cycle

1 day

3 days

+67%

Indicator

JS scheme

Other printing shops

Efficiency improvement

Equipment downtime

2 hours/week

5 hours/week

+60%

Unit energy consumption cost

$0.8/hour

$1.2/hour

+33%

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources