In der modernen Produktentwicklung ist schnelles Prototyping von Konzept zur Kernbrücke geworden. Rapid Prototyping ist eine schnelle Methode, um Prototypen durch Techniken wie 3D-Druck- und CNC-Bearbeitung zu konstruieren , die digitale Designs in eine Kurzzeit in konkrete, messbare physische Objekte verwandeln können. RapiD-Data-V-7b79c893 = "> RapiD-Daten-V-7b79c893 =" " Innovation durch Verkürzung der Iterationszyklen und Reduzierung von Versuchs- und Fehlerkosten, ob die Benutzerinteraktionserfahrung die Benutzerinteraktion oder die strukturelle Stärke testen.

Sein Kernwert liegt darin, Probleme aufzudecken, die in den späteren Stadien der traditionellen Entwicklung in den frühen Stadien des Designs auftreten, wodurch sich die Verschwendung von Ressourcen stark verringern. In diesem THE-DATE-V-7B79C893 =" "> In diesem Tith-V-7b79c893 =" ""> In diesem Tith-V-7b79c893 = ""> In diesem SPAN-DATE-V-7B79C893 = "" handelt werden s, s ,eitululeitet keitet9eiteteitetstelltnenentententent Wenn Sie in schnellem Prototyping ausgewogen werden, wird eingehend diskutiert, und wie man kollaborative Durchbrüche in Effizienz und Qualität durch wissenschaftliche Entscheidungsfindung erzielt.

Was ist schnelles Prototyping und was ist sein Kernziel?

Rapid Prototyps ist eine Methode zum Konstruktion des Prototyping-Modells durch 3D-Druck, CNC-Bearbeitung, Injektionsformungen und so weiter. Dieser Verifizierungsmodus beschleunigt nicht nur die Konvertierungseffizienz, sondern hilft dem Team auch, die Entwurfsrationalität in intuitiver durch physikalische Modelle zu bewerten, das Risiko einer späteren Massenproduktion reduzieren .

Warum ist schnell Prototyping ein unverzichtbarer Teil der Produktentwicklung?

Auf dem heutigen äußerst wettbewerbsintensiven Markt ist der schnelle Prototyp zur kernkatalistischen Produktentwicklung von Konzept zur Massenproduktion geworden. 1. Data-Len = "28" Daten-V-7b79c893 = ""> Versuchs- und Fehlerkosten reduzieren

Rapid Prototyping Visualisierung von Designdetails durch physikalische Modelle und hilft dem Team dabei, potenzielle Fehler vor der Massenproduktion zu identifizieren. JS-Firma ">

JS hat 1-2 Wochen schneller Lieferkapazität (98% der Bestellungen sind pünktlich), sodass Unternehmen mehrere Designs in kürzester Zeit testen können. ANDAGE DATA-V-7B79C893 = "A. hat das Prototyping eines Lenksystems in 3 Tagen mit einer Geschwindigkeitssteigerung von 80% im Vergleich zu herkömmlichen Methoden abgeschlossen, was ihm einen Rand über dem Markt verleiht.

3. Data-Len = "53" Data-V-7B79C893 = ""> Multi-Material-Anpassung und funktionale Überprüfung

JS unterstützt die Verarbeitungsfunktionen von mehr als 50 Materialien, einschließlich Metallen, Plastik und Verbundwerkstoffen, um die Bedürfnisse von leichten bis heizungsbeständigen Bedürfnissen zu erfüllen.

JS optimiert intelligente Fertigungsprozesse und senkt durchschnittlich die durchschnittlichen Prototypen-Herstellungskosten um 20% und die Projektleitungen um 15%. ITRAGATION DATA-V-7B79C893 Dateien im 20+ -Format, wie z.

5. Data-Len = "19" Data-V-7b79c893 = ""> Green Manufacturing JS 'umweltfreundliche Prozesse wie 30% materielle Wiederherstellung und 15% Energieverbrauch sind mit schnellen Prototyping-Anforderungen stark kompatibel. Ein neuer Energiekunde validierte erfolgreich die Nachhaltigkeit des Produkts des Produkts.

1. Data-Len = "40" Daten-V-7b79c893 = ""> Multi-Prozess-Kollaborative Optimierung Um die mehrdimensionalen Anforderungen komplexer Prototypstrukturen zu erfüllen, übernimmt JS die Prozessstrategie von CNC-Bearbeitung und 3D-Prachtzeilen. F oder Beispiel, t Hin-Wanded Metall-Teile mit Precision mit einem Fünf-Axis-CNC-Maschinen. Funktionstestanforderungen und reduzieren die Lieferzyklen. 2. Data-Len = "34" Data-V-7b79c893 = ""> Geräte mit hoher Präzisionsgarantien Js ± 0,005 mm CNC-Bearbeitungsgenauigkeit und 3D-Druckauflösung von Industriegrads können die geometrischen Merkmale komplexer Prototypen genau reproduzieren. Prototypes of aviation component require processing of 0,3 mm Mikroporenarrays mit einer Dicke von 5 mm. durch Layer-7b79c893 =" "> durch LAY-V-7B79C893 =" "" JS implementiert erfolgreich die Entwurfsanforderungen. 3. Data-V-7B79C893 = ""> Materialanpassungsfähigkeit JS 'Materialsressourcenbibliothek kann eine Vielzahl von Optionen für unterschiedliche strukturelle Eigenschaften bereitstellen. 4. Data-Len = "41" Daten-V-7b79c893 = ""> Digitale Simulation und Prozessvalidierung Vor der Produktion verwendet JS die CAE-Simulationstechnologie, die die Verarbeitungsrisiken vorhersagen und die Verarbeitung durch schnelles Mockup verifizieren. <"> 5. Schnelle Antwort und Iteration JS '24-Stunden-technischer Antwortmechanismus und automatisierte Anführungssystem-Unterstützung Kunden, um das Design während des Rapid Mockup Phase. Ein Prototyp-Robotergelenk Die Standards für Stresstests und JS-Materialsänderungen und Prozesskorrekturen innerhalb von 48 Stunden nicht erfüllt, um sicherzustellen, dass das Projekt pünktlich war.

1. Data-Len = "35" Daten-V-7b79c893 = ""> Erweiterung der Leistungsgrenzen aufkommende Materialien haben durch die physischen Grenzen herkömmlicher Materialien gebrochen und neue Wege für schnelle Prototypen zur Funktion und Strukturdesign geöffnet. für Data-V-7b79c893 =" " Beispiel: 2. Data-V-7b79c893 = ""> Herausforderungen der Prozessanpassung Die eindeutigen Eigenschaften aufkommender Materialien werden häufig von zunehmenden Verarbeitungsschwierigkeiten begleitet.

3. Data-Len = "35" Daten-V-7b79c893 = ""> nachhaltige Entwicklung und kreisförmige Wirtschaft Emerging Materials Drive Rapid Prototypen Übergang zum Umgebungsschutz: 4. Innovatives Design Thinking aufkommende Materialien führen zu neuen Designparadigmen, die mit der herkömmlichen technischen Logik brechen: In the field of rapid prototyping, CNC machining is the core technology for verifying complex structures and functions with high precision, high flexibility and wide range of material adaptability 1.High-precision complex structure prototype 2.Strict tolerance requirements 3.Quick prototypes switch with multiple materials 4.Rapid iteration of functional prototypes 5.High-surface quality prototype The surface roughness (Ra 0.8-3.2μm) of CNC processed products can be directly used for appearance verification or precision assembly. JS technical support: Standard post-treatment processes such as mirror polishing, sandblasting, anodic oxidation, etc. A prototype of a consumer electronics is verified by numerical CNC machining PVD coating synchronize metal texture with IP67 waterproof performance. Prototyped verification for medical devices and consumer electronics are completely different depending on application scenarios, safety risks and regulatory requirements: 1.Regulatory and certification requirements 2.Test items and standards 3.Material selection and limitations 4.Verification cycle and cost Validation standards for medical device prototypes focus on safety, taking into account regulations, biocompatibility and long-term reliability. Consumer electronics prototypes are user experience-oriented and cost effective. JS Company offers bespoke solutions for both prototypes with 98% on-time delivery and 20% cost savings, helping customers balance stringent standards with market opportunities. 1.Rapid delivery from month to day Whereas traditional manufacturing relies on mold development and long-term scheduling, JS uses a hybrid process line for rapid prototyping: 2.Beyond the standard of traditional craft Whereas traditional manufacturing is limited by device precision and manual operation, JS rapid prototyping relies on cutting-edge technology to achieve micrometer level control: 3.Addressing multi-material verification requirements Whereas traditional manufacturing is constrained by a single material supply, JS has built an ecosystem of more than 50 materials, covering all scenarios of metals, plastics and composites: 4.Low-cost trial and error Whereas traditional manufacturing requires high mold costs and the risk of mass production, JS's rapid prototyping reduces costs through the following strategies: 5.Change from prototype to mass production Traditional manufacturing has pain point of disconnection between prototyping and mass production, and JS has achieved a smooth transition from rapid prototyping to mass production through its vertical integration capability: JS rapid prototyping service core indicators Prototyping meaning transforming abstract concepts into verifiable entity models by minimizing time and resource investment, thus accelerating innovation iterations and reducing development risks. Its essence is not only technological innovation, but also the validation of design-driven thinking paradigms that seek the best balance between functionality, cost, and user experience by rapidly constructing prototyping model. Rapid prototyping design enhances agility and responsiveness to feedback while improving accuracy and scalability, ultimately compressing development cycles, reducing trial and error risks, and translating uncertainty into actionable executable engineering insights, making it an indispensable approach in modern product development. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.What are the advantages of CNC machining in prototypes? The advantages of CNC machining are high precision, high efficiency, good material compatibility, good surface quality, and suitable for rapid prototyping of complex structures. 2.What are the tolerance control standards for rapid prototyping? Rapid prototyping tolerances are adjusted according to process and material (e.g. FDM ±0.2-0.5mm), with the core meeting functional requirements rather than extreme precision to reduce costs and accelerate validation. 3.How does rapid prototyping respond to mass production needs? Rapid prototyping reduces validation cycle times, reduces production risks and ensures a smooth transition from design to large-scale production by early validation of design feasibility, optimization of structures and adaptation to large-scale production processes. 4.How to achieve customized requirements through rapid prototyping? Driven directly by digital design, without the need for traditional moulds, it supports flexible adjustments, responds quickly to personalized or small-batch needs, and reduces customization costs and cycles. Wie kann das Schlüsseldesign komplexer Prototypen durch Prozessauswahl erreicht werden?

Was sind die Auswirkungen aufkommender Materialien auf das Prototypdesign?

Materialtyp

Kernfunktionen

direkte Auswirkungen auf das Prototypdesign

Kohlefaser verstärkte Kunststoff

hohe spezifische Festigkeit und Leichtgewicht.

15% -30% Gewichtsreduzierung für Luft- und Raumfahrt-Präzisionskomponenten.

Metallic Glass

Keine Korngrenzendefekte, korrosionsbeständige.

Dünnwandige Strukturen verbessern die Ermüdungsbeständigkeit und sind für medizinische Implantate geeignet.

Formgedächtnispolymer

Temperaturreformation Verformung.

Prototyp-Validierung dynamischer Anschlüsse und bereitgestellter Satellitenkomponenten.

Materialtyp

Umwelteigenschaften

Anwendungsszenarien und Vorteile

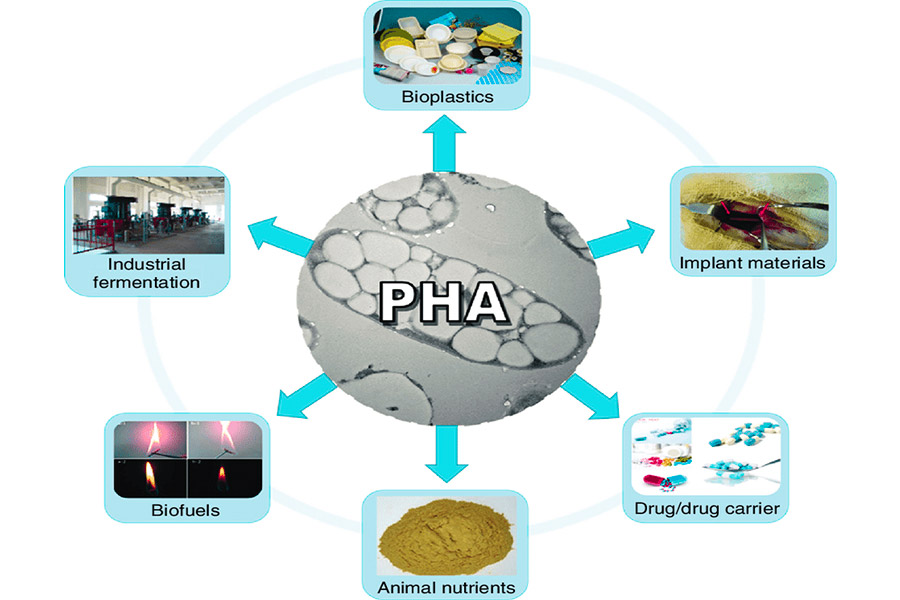

PHA (Polyhydroxyalkanoates)

Der industrielle Kompost verschlechtert sich vollständig in 180 Tagen.

Prototypen von Einweg-Medizinprodukten ohne verbleibende Kontamination.

Regenerierte Kohlefaser

Carbonfaserwiederherstellung ≥ 90%.

Neue Energie für Energieauto-Batteriebox Prototyped, 20% Gewichtsreduzierung, Energieverbrauch.

What are the advantageous scenarios of CNC machining in rapid prototyping?

Medical device prototype vs. consumer electronics prototype: what are the differences in verification standards?

Dimension

Medical device prototype

Consumer electronics prototype

JS support

Core certification

FDA 510(k)、CE MDR、ISO 13485.

FCC certification, CE certification, UL certification.

Provide material compliance verification and assist in the submission of certification documents.

Approval cycle

6-18 months (including clinical trials and ethical review).

2-6 months.

Accelerate prototype iteration to match authentication time nodes.

Document integrity

A complete risk analysis report and clinical data support are required.

Focus on functional and safety testing reports.

Provides full-process document management services.

Dimension

Medical device prototype

Consumer electronics prototype

JS support

Biocompatibility

ISO 10993 (Cytotoxicity, Allergy Testing).

There are no mandatory requirements.

Medical grade materials such as titanium alloy and PEEK are available.

Environmental adaptability

High temperature and autoclaving (ETO, gamma rays) tests are required.

IP waterproof rating, high and low temperature cycling test.

Supports vacuum coating, anodic oxidation and other surface treatment processes.

Functional verification

Simulate human usage scenarios (e.g. implant fatigue life testing).

Drop test, button life test.

Customized fixture development and automated testing platform.

Dimension

Medical device prototype

Consumer electronics prototype

JS support

Material safety

Only FDA approved biocompatible materials (such as ABS-M30i) are allowed.

Widely used are plastics, metals, and composite materials.

Inventory of over 50 types of medical/industrial grade materials.

Durability requirements

Must have a service life of at least 5 years.

Usually, the product design cycle is 2-3 years.

Provide material aging testing and accelerated life assessment.

Compliance constraints

Prohibit the use of carcinogens (such as DEHP plasticizers).

Focus on lightweight and cost optimization.

Material composition traceability and environmental certification support.

Dimension

Medical device prototype

Consumer electronics prototype

JS support

Prototype delivery cycle

3-6 months (including multiple design iterations).

1-3 weeks (quick sampling).

24-hour technical response, priority scheduling of emergency orders.

Single verification cost

High (including certification fees and clinical sample fees).

Low (material and processing costs only).

Optimize the process to reduce prototype production costs by 30%.

Cost risk of failure

Very high (recall losses can run into billions of dollars).

Medium (brand reputation and after-sales service costs).

Provide DFM (Manufacturing Design) optimization suggestions.

What are the unique competitive advantages of JS's rapid prototyping service compared to traditional manufacturing?

Competitive dimension

JS rapid prototyping

Traditional manufacturing mode

Technical gap

First version delivery cycle

1-3 days.

2-4 weeks.

80% acceleration.

Minimum processing size

0.02mm thin-walled structure.

Minimum order of 0.5mm.

25 times accuracy improvement.

Optional types of materials

More than 50 types(metal/plastic/composite materials)

5-10 standardized materials.

10 times the selection space.

Comprehensive cost

Reduce small batch costs by 70%

Mold costs account for over 60%.

Cost structure reconstruction.

Mass production conversion rate

90% of prototypes can be directly imported into mass production

Mass production yield fluctuates greatly, requiring repeated debugging.

Pre risk, increased success rate.

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources